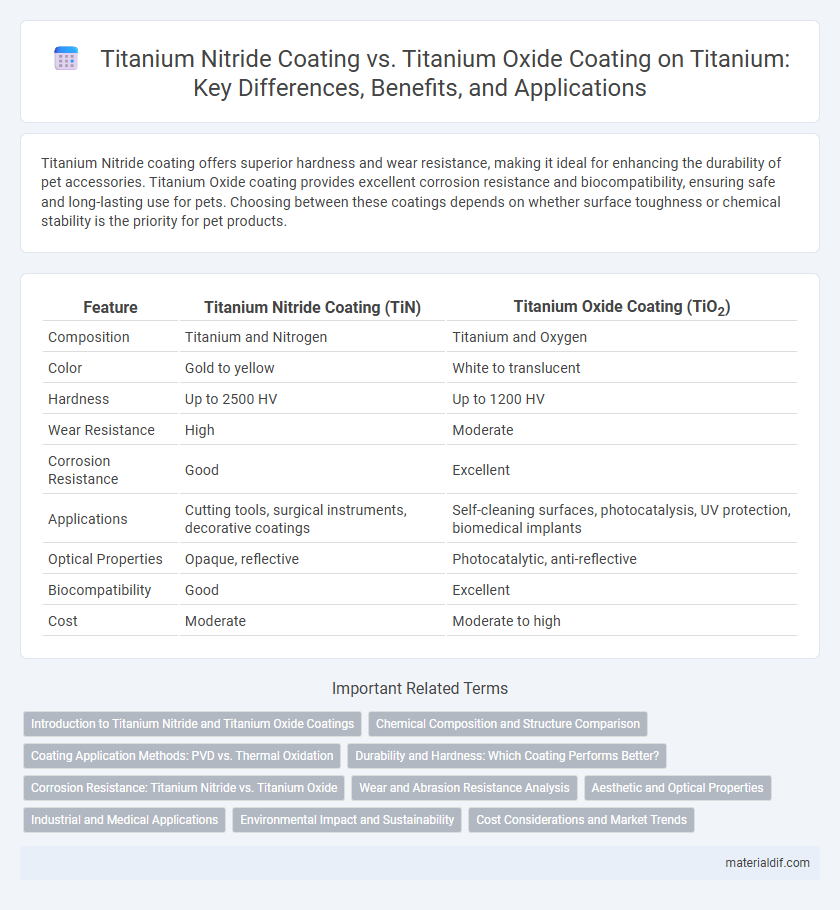

Titanium Nitride coating offers superior hardness and wear resistance, making it ideal for enhancing the durability of pet accessories. Titanium Oxide coating provides excellent corrosion resistance and biocompatibility, ensuring safe and long-lasting use for pets. Choosing between these coatings depends on whether surface toughness or chemical stability is the priority for pet products.

Table of Comparison

| Feature | Titanium Nitride Coating (TiN) | Titanium Oxide Coating (TiO2) |

|---|---|---|

| Composition | Titanium and Nitrogen | Titanium and Oxygen |

| Color | Gold to yellow | White to translucent |

| Hardness | Up to 2500 HV | Up to 1200 HV |

| Wear Resistance | High | Moderate |

| Corrosion Resistance | Good | Excellent |

| Applications | Cutting tools, surgical instruments, decorative coatings | Self-cleaning surfaces, photocatalysis, UV protection, biomedical implants |

| Optical Properties | Opaque, reflective | Photocatalytic, anti-reflective |

| Biocompatibility | Good | Excellent |

| Cost | Moderate | Moderate to high |

Introduction to Titanium Nitride and Titanium Oxide Coatings

Titanium Nitride (TiN) coating offers exceptional hardness, wear resistance, and a characteristic golden appearance, making it ideal for cutting tools and medical implants. Titanium Oxide (TiO2) coating is prized for its photocatalytic properties, UV resistance, and biocompatibility, commonly used in self-cleaning surfaces and sunscreens. Both coatings enhance titanium's surface performance but serve distinct industrial applications due to their unique chemical and physical properties.

Chemical Composition and Structure Comparison

Titanium Nitride (TiN) coating consists of a ceramic compound formed by the reaction of titanium and nitrogen atoms, featuring a face-centered cubic crystalline structure that provides excellent hardness and wear resistance. Titanium Oxide (TiO2) coating is primarily composed of titanium and oxygen atoms, typically exhibiting a rutile or anatase crystalline phase known for superior photocatalytic activity and chemical stability. The TiN coating's dense and metallic-like lattice contrasts with TiO2's more porous and oxide-based structure, influencing their respective applications in cutting tools and protective surfaces versus self-cleaning and anti-corrosive technologies.

Coating Application Methods: PVD vs. Thermal Oxidation

Titanium Nitride (TiN) coatings are predominantly applied using Physical Vapor Deposition (PVD), a vacuum-based technique that produces a hard, wear-resistant layer with excellent adhesion and uniform thickness. In contrast, Titanium Oxide (TiO2) coatings are commonly created through thermal oxidation, a high-temperature process that forms an oxide layer by exposing titanium surfaces to oxygen, enhancing corrosion resistance and biocompatibility. PVD offers precise control over coating composition and microstructure, while thermal oxidation is cost-effective and suitable for forming stable oxide films on complex geometries.

Durability and Hardness: Which Coating Performs Better?

Titanium Nitride (TiN) coating exhibits superior hardness with a typical hardness rating of 2,200 HV, significantly outperforming Titanium Oxide (TiO2), which generally measures around 800 HV. In terms of durability, TiN coatings provide enhanced wear resistance, making them ideal for cutting tools and high-friction applications, while TiO2 coatings offer better corrosion resistance but lower mechanical strength. For environments requiring maximum hardness and abrasion resistance, Titanium Nitride coating performs better than Titanium Oxide.

Corrosion Resistance: Titanium Nitride vs. Titanium Oxide

Titanium Nitride (TiN) coating exhibits superior corrosion resistance due to its dense, inert ceramic layer that effectively prevents oxidation and chemical degradation in harsh environments. Titanium Oxide (TiO2) coating, while providing good corrosion protection through its stable oxide film, is more susceptible to cracking under mechanical stress, potentially compromising its barrier properties. TiN coatings are preferred in applications demanding enhanced durability against corrosive agents, ensuring prolonged component lifespan.

Wear and Abrasion Resistance Analysis

Titanium nitride coating exhibits superior wear and abrasion resistance compared to titanium oxide coating due to its higher hardness and dense microstructure, making it ideal for cutting tools and high-friction applications. Titanium oxide coatings provide excellent corrosion resistance and photocatalytic properties but have lower hardness, resulting in less effective protection against mechanical wear. Studies show titanium nitride's hardness typically ranges from 1800 to 2200 HV, significantly outperforming titanium oxide's hardness of around 500 to 700 HV, thus extending the lifespan of coated components under abrasive conditions.

Aesthetic and Optical Properties

Titanium Nitride coating exhibits a distinctive gold-like color with high reflectivity, enhancing the aesthetic appeal of jewelry and decorative items through its metallic luster and durability. Titanium Oxide coating, particularly in its anatase and rutile forms, offers superior optical properties such as high refractive index and strong UV light scattering, making it ideal for applications requiring enhanced whiteness and brightness. The choice between Titanium Nitride and Titanium Oxide coatings depends on the desired visual effect--metallic sheen versus bright, white opacity--and their specific reflectance and color stability under various lighting conditions.

Industrial and Medical Applications

Titanium Nitride (TiN) coating offers exceptional hardness, wear resistance, and biocompatibility, making it ideal for cutting tools, medical implants, and surgical instruments. Titanium Oxide (TiO2) coating excels in corrosion resistance, photocatalytic properties, and antimicrobial activity, which are crucial in medical devices and sterilization equipment. Both coatings enhance the durability and performance of industrial components and medical tools by providing tailored surface protection and improved functionality.

Environmental Impact and Sustainability

Titanium Nitride (TiN) coatings are prized for their hardness and wear resistance but require energy-intensive physical vapor deposition processes, contributing to a higher carbon footprint compared to Titanium Oxide (TiO2) coatings, which are often produced through more sustainable sol-gel or thermal oxidation methods. Titanium Oxide coatings offer photocatalytic properties that enable environmental benefits such as air purification and self-cleaning surfaces, enhancing sustainability by reducing the need for chemical cleaners. The recyclability and non-toxic nature of TiO2 coatings further improve their environmental profile, making them a preferred choice for eco-friendly applications.

Cost Considerations and Market Trends

Titanium Nitride (TiN) coating generally commands higher costs due to its complex application process and superior hardness properties, making it favored in high-performance industrial tools and medical devices. Titanium Oxide (TiO2) coatings are more cost-effective, widely adopted in consumer goods and environmental applications, driven by their photocatalytic and corrosion resistance benefits. Market trends indicate growing demand for TiO2 in sustainable technologies, while TiN maintains steady growth in sectors prioritizing durability and wear resistance.

Titanium Nitride Coating vs Titanium Oxide Coating Infographic

materialdif.com

materialdif.com