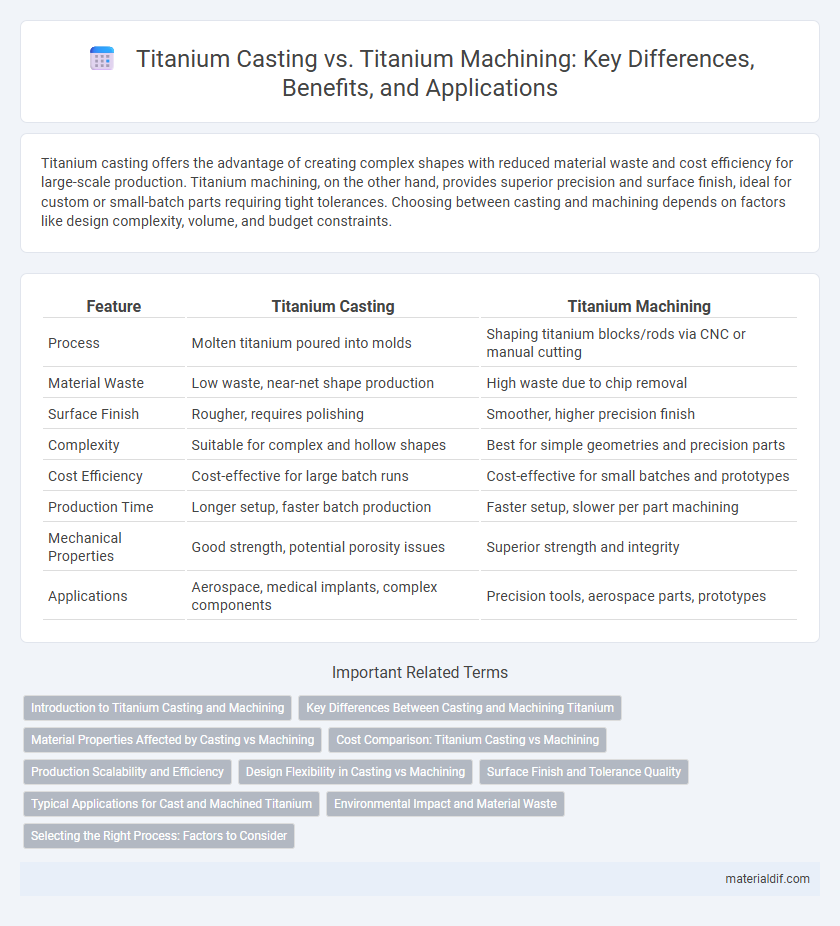

Titanium casting offers the advantage of creating complex shapes with reduced material waste and cost efficiency for large-scale production. Titanium machining, on the other hand, provides superior precision and surface finish, ideal for custom or small-batch parts requiring tight tolerances. Choosing between casting and machining depends on factors like design complexity, volume, and budget constraints.

Table of Comparison

| Feature | Titanium Casting | Titanium Machining |

|---|---|---|

| Process | Molten titanium poured into molds | Shaping titanium blocks/rods via CNC or manual cutting |

| Material Waste | Low waste, near-net shape production | High waste due to chip removal |

| Surface Finish | Rougher, requires polishing | Smoother, higher precision finish |

| Complexity | Suitable for complex and hollow shapes | Best for simple geometries and precision parts |

| Cost Efficiency | Cost-effective for large batch runs | Cost-effective for small batches and prototypes |

| Production Time | Longer setup, faster batch production | Faster setup, slower per part machining |

| Mechanical Properties | Good strength, potential porosity issues | Superior strength and integrity |

| Applications | Aerospace, medical implants, complex components | Precision tools, aerospace parts, prototypes |

Introduction to Titanium Casting and Machining

Titanium casting involves pouring molten titanium into molds to create complex shapes with high strength-to-weight ratios, suitable for aerospace and medical applications. Titanium machining uses precise cutting tools to shape solid titanium billets, offering superior surface finish and tight dimensional tolerances for critical components. Both methods optimize titanium's corrosion resistance and biocompatibility but differ in production speed, cost, and design flexibility.

Key Differences Between Casting and Machining Titanium

Titanium casting involves pouring molten metal into molds to create complex shapes with minimal waste, while titanium machining uses cutting tools to remove material from solid blocks, offering higher precision and tighter tolerances. Casting typically suits large, intricate components but may result in variable microstructures and surface finish, whereas machining provides superior surface quality and uniform mechanical properties. Cost considerations differ as casting reduces material loss but requires expensive mold creation, whereas machining incurs higher tool wear and longer processing times.

Material Properties Affected by Casting vs Machining

Titanium casting often results in microstructural variations such as grain size heterogeneity and porosity, which can reduce mechanical properties like tensile strength and fatigue resistance compared to wrought or machined titanium. Machining titanium from wrought bars maintains uniform grain structure and higher density, leading to superior surface finish and consistent material properties. The inherent differences in cooling rates during casting versus the controlled deformation in machining significantly influence hardness, ductility, and corrosion resistance of the final titanium components.

Cost Comparison: Titanium Casting vs Machining

Titanium casting typically incurs lower initial costs compared to machining due to reduced material waste and ability to produce complex shapes in fewer steps, benefiting large or intricate parts. Machining titanium, however, demands expensive tooling and slower processing times because of the metal's hardness and toughness, increasing labor and machine wear costs. Overall, casting proves more cost-effective for high-volume or complex geometries, while machining suits low-volume, precision applications despite higher per-unit expenses.

Production Scalability and Efficiency

Titanium casting enables the production of complex shapes with reduced machining steps, enhancing scalability for large volumes while maintaining material efficiency through near-net-shape processes. Titanium machining offers high precision and surface finish but involves longer cycle times and increased tool wear, limiting its efficiency for high-volume production. Selecting between casting and machining depends on balancing production scalability with the desired tolerances and design complexity in aerospace and medical applications.

Design Flexibility in Casting vs Machining

Titanium casting offers greater design flexibility by enabling complex geometries and intricate internal features that are difficult or impossible to achieve through machining. Machining titanium is often limited by tool access and the material's hardness, restricting the design to simpler shapes and requiring extensive post-processing. Casting allows for near-net-shape production, reducing waste and enabling customized designs tailored to specific engineering requirements.

Surface Finish and Tolerance Quality

Titanium casting offers complex shapes and cost efficiency but typically results in a rougher surface finish and wider tolerance ranges due to mold limitations. Titanium machining provides superior surface finish quality with smoother textures and tighter tolerance control, essential for high-precision aerospace and biomedical components. Machining also allows post-processing improvements, enhancing dimensional accuracy beyond cast parts.

Typical Applications for Cast and Machined Titanium

Titanium casting is typically used for complex geometries in aerospace components, medical implants, and automotive parts where high strength-to-weight ratio and corrosion resistance are critical. Machined titanium is preferred for precision parts such as fasteners, aerospace turbine blades, and medical surgical instruments requiring tight tolerances and smooth surface finishes. Both processes leverage titanium's exceptional properties, with casting suited for intricate shapes and machining ideal for detailed, high-precision applications.

Environmental Impact and Material Waste

Titanium casting generates less material waste compared to titanium machining, which often results in substantial scrap due to the subtractive nature of the process. The casting process typically uses precise mold designs that optimize material use and reduce energy consumption, leading to a lower environmental footprint. In contrast, machining titanium requires significant energy input and coolant usage, contributing to higher environmental impact and waste disposal challenges.

Selecting the Right Process: Factors to Consider

Selecting the right process between titanium casting and titanium machining depends on factors such as part complexity, production volume, and cost efficiency. Titanium casting is ideal for intricate shapes and lower production runs, offering material savings and design flexibility. Titanium machining suits high-precision components and large-scale manufacturing, ensuring superior surface finish and tight dimensional tolerances.

Titanium Casting vs Titanium Machining Infographic

materialdif.com

materialdif.com