Titanium fasteners offer superior corrosion resistance and lightweight strength compared to stainless steel fasteners, making them ideal for demanding environments. They provide exceptional durability and are less prone to galvanic corrosion, ensuring long-lasting performance in marine and aerospace applications. While stainless steel fasteners are cost-effective and widely used, titanium fasteners deliver enhanced reliability and longevity where strength-to-weight ratio is critical.

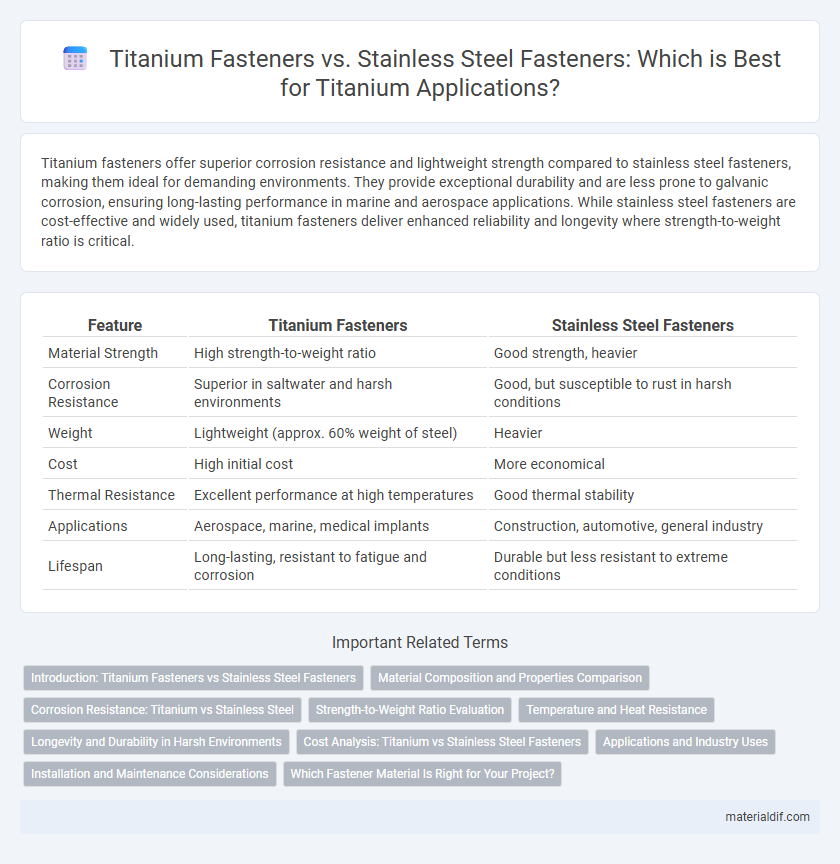

Table of Comparison

| Feature | Titanium Fasteners | Stainless Steel Fasteners |

|---|---|---|

| Material Strength | High strength-to-weight ratio | Good strength, heavier |

| Corrosion Resistance | Superior in saltwater and harsh environments | Good, but susceptible to rust in harsh conditions |

| Weight | Lightweight (approx. 60% weight of steel) | Heavier |

| Cost | High initial cost | More economical |

| Thermal Resistance | Excellent performance at high temperatures | Good thermal stability |

| Applications | Aerospace, marine, medical implants | Construction, automotive, general industry |

| Lifespan | Long-lasting, resistant to fatigue and corrosion | Durable but less resistant to extreme conditions |

Introduction: Titanium Fasteners vs Stainless Steel Fasteners

Titanium fasteners offer exceptional strength-to-weight ratio and superior corrosion resistance compared to stainless steel fasteners, making them ideal for aerospace, marine, and chemical processing industries. Stainless steel fasteners provide excellent durability and cost-effectiveness but can be prone to corrosion in highly aggressive environments. Selecting between titanium and stainless steel fasteners depends on application-specific requirements such as mechanical performance, environmental exposure, and budget constraints.

Material Composition and Properties Comparison

Titanium fasteners are composed primarily of titanium alloys, offering exceptional strength-to-weight ratio and superior corrosion resistance compared to stainless steel fasteners, which contain iron, chromium, and nickel alloys. Titanium's biocompatibility and resistance to stress corrosion cracking make it ideal for aerospace and medical applications, whereas stainless steel fasteners provide higher hardness and are more cost-effective for general engineering purposes. The lower density of titanium results in lighter fasteners without sacrificing mechanical strength, enhancing performance in weight-sensitive environments.

Corrosion Resistance: Titanium vs Stainless Steel

Titanium fasteners exhibit superior corrosion resistance compared to stainless steel fasteners due to titanium's natural oxide layer, which provides excellent protection in highly corrosive environments such as marine and chemical applications. Stainless steel fasteners, particularly those made from 316-grade, offer good corrosion resistance but are prone to pitting and crevice corrosion under aggressive conditions. The enhanced durability of titanium fasteners makes them ideal for long-term use where exposure to saltwater, acids, or extreme weather is a concern.

Strength-to-Weight Ratio Evaluation

Titanium fasteners exhibit a superior strength-to-weight ratio compared to stainless steel fasteners, providing high tensile strength while significantly reducing overall component weight. This advantage makes titanium fasteners ideal for aerospace, automotive, and high-performance engineering applications where minimizing mass without compromising durability is critical. Despite stainless steel's corrosion resistance, titanium's combination of lightness and mechanical performance drives its selection in weight-sensitive designs.

Temperature and Heat Resistance

Titanium fasteners exhibit superior temperature and heat resistance compared to stainless steel fasteners, maintaining strength and structural integrity at temperatures up to 600degC (1112degF) without significant deformation. Stainless steel fasteners, particularly austenitic grades like 304 and 316, start to lose strength and corrosion resistance above 400degC (752degF), making them less suitable for high-temperature applications. This distinct thermal stability makes titanium fasteners ideal for aerospace, automotive exhaust systems, and industrial heat exchangers where consistent performance under extreme heat is critical.

Longevity and Durability in Harsh Environments

Titanium fasteners exhibit superior longevity and durability compared to stainless steel fasteners, especially in harsh environments such as marine or chemical settings due to their exceptional corrosion resistance and high strength-to-weight ratio. Unlike stainless steel, titanium resists corrosion from saltwater, chlorides, and acidic conditions without rusting or weakening over time. This makes titanium fasteners ideal for aerospace, marine, and industrial applications where long-term reliability and maintenance reduction are critical.

Cost Analysis: Titanium vs Stainless Steel Fasteners

Titanium fasteners generally have a higher upfront cost compared to stainless steel fasteners due to the expensive raw materials and complex manufacturing processes involved in titanium production. Despite the initial expense, titanium fasteners offer superior corrosion resistance, strength-to-weight ratio, and longevity, which can lead to reduced maintenance and replacement costs in the long term. Stainless steel fasteners are more budget-friendly initially but may incur higher lifecycle expenses in corrosive or high-stress environments due to their lower durability compared to titanium.

Applications and Industry Uses

Titanium fasteners excel in aerospace, automotive, and marine industries due to their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal for high-performance and corrosive environments. Stainless steel fasteners are widely used in construction, food processing, and chemical industries for their durability, cost-effectiveness, and resistance to oxidation and chemical exposure. Both materials serve critical roles where mechanical performance and environmental resistance are essential but diverge based on weight constraints and specific corrosion challenges.

Installation and Maintenance Considerations

Titanium fasteners offer superior corrosion resistance and a lightweight advantage, reducing installation time due to easier handling and reduced torque requirements compared to stainless steel fasteners. Stainless steel fasteners require more frequent inspection and preventive maintenance to avoid galling and corrosion, particularly in marine or high-humidity environments. Installation of titanium fasteners demands careful attention to avoid galling, often necessitating lubrication, but their reduced maintenance frequency results in lower long-term operational costs.

Which Fastener Material Is Right for Your Project?

Titanium fasteners offer superior corrosion resistance and a high strength-to-weight ratio, making them ideal for aerospace and marine applications where durability and weight savings are critical. Stainless steel fasteners provide excellent corrosion resistance with greater cost efficiency, commonly used in construction and automotive industries where budget and strength are balanced. Choosing the right material depends on project requirements including environmental exposure, mechanical load, and budget constraints to ensure optimal performance and longevity.

Titanium Fasteners vs Stainless Steel Fasteners Infographic

materialdif.com

materialdif.com