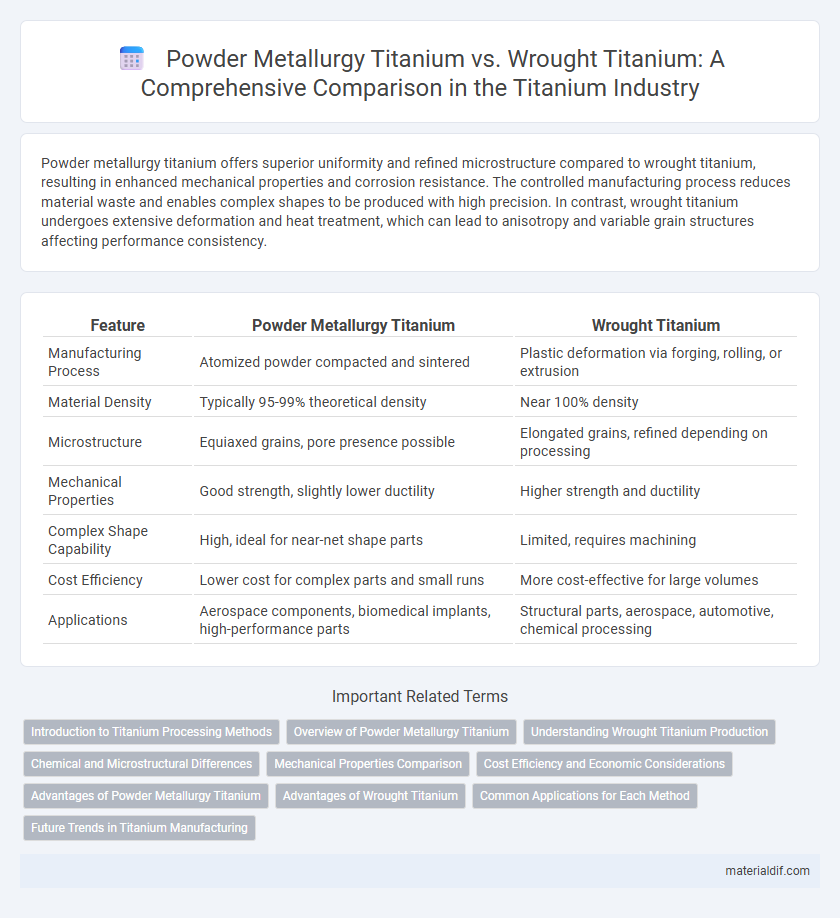

Powder metallurgy titanium offers superior uniformity and refined microstructure compared to wrought titanium, resulting in enhanced mechanical properties and corrosion resistance. The controlled manufacturing process reduces material waste and enables complex shapes to be produced with high precision. In contrast, wrought titanium undergoes extensive deformation and heat treatment, which can lead to anisotropy and variable grain structures affecting performance consistency.

Table of Comparison

| Feature | Powder Metallurgy Titanium | Wrought Titanium |

|---|---|---|

| Manufacturing Process | Atomized powder compacted and sintered | Plastic deformation via forging, rolling, or extrusion |

| Material Density | Typically 95-99% theoretical density | Near 100% density |

| Microstructure | Equiaxed grains, pore presence possible | Elongated grains, refined depending on processing |

| Mechanical Properties | Good strength, slightly lower ductility | Higher strength and ductility |

| Complex Shape Capability | High, ideal for near-net shape parts | Limited, requires machining |

| Cost Efficiency | Lower cost for complex parts and small runs | More cost-effective for large volumes |

| Applications | Aerospace components, biomedical implants, high-performance parts | Structural parts, aerospace, automotive, chemical processing |

Introduction to Titanium Processing Methods

Powder metallurgy titanium offers superior control over alloy composition and microstructure compared to wrought titanium, enabling complex shapes and fine microstructures that improve mechanical properties. This process involves atomizing titanium into fine powders, which are then compacted and sintered to form dense, near-net shape components. Wrought titanium processing, involving forging, rolling, and extrusion, provides excellent strength and toughness but is limited in geometric complexity and requires extensive machining.

Overview of Powder Metallurgy Titanium

Powder metallurgy titanium is produced by compacting and sintering titanium powders, resulting in complex shapes with minimal material waste and enhanced mechanical properties. This manufacturing method allows precise control over microstructure and porosity, offering superior strength-to-weight ratios compared to conventional wrought titanium. Applications in aerospace, biomedical implants, and automotive components benefit from powder metallurgy's ability to create near-net-shape parts with excellent performance characteristics.

Understanding Wrought Titanium Production

Wrought titanium production involves mechanically working titanium ingots through processes such as rolling, forging, and extrusion to enhance strength, ductility, and grain structure uniformity. This method offers superior control over microstructure and mechanical properties compared to powder metallurgy titanium, making it ideal for aerospace and biomedical applications requiring high fatigue resistance. The controlled deformation and heat treatment cycles in wrought titanium production result in materials with optimized toughness and corrosion resistance.

Chemical and Microstructural Differences

Powder metallurgy titanium exhibits a more homogeneous microstructure with finer alpha grain size compared to wrought titanium, resulting from rapid solidification during powder processing. Chemically, powder metallurgy titanium typically has lower residual oxygen and nitrogen levels, enhancing ductility and fatigue resistance relative to wrought counterparts. These differences contribute to improved mechanical properties and corrosion resistance in applications requiring precise chemical control and microstructural uniformity.

Mechanical Properties Comparison

Powder metallurgy titanium exhibits superior homogeneity and fine microstructure, resulting in enhanced tensile strength and fatigue resistance compared to wrought titanium. Wrought titanium provides better ductility and fracture toughness due to its forged and rolled grain structure, making it more suitable for applications requiring high deformation capacity. Both methods offer distinct mechanical advantages tailored to specific industrial demands, with powder metallurgy favored for complex geometries and wrought titanium preferred for structural components.

Cost Efficiency and Economic Considerations

Powder metallurgy titanium offers significant cost efficiency compared to wrought titanium by minimizing material waste and reducing machining time, which lowers overall production expenses. The near-net-shape manufacturing process of powder metallurgy allows for complex geometries that would be cost-prohibitive with wrought titanium due to extensive machining and material removal. Economic considerations favor powder metallurgy titanium in high-volume or precision applications where reducing raw material and processing costs directly impacts profitability.

Advantages of Powder Metallurgy Titanium

Powder metallurgy titanium offers superior uniformity in microstructure and enhanced material properties such as increased strength and improved fatigue resistance compared to wrought titanium. The process allows for near-net shape manufacturing, reducing material waste and machining costs while enabling complex geometries that are difficult to achieve with wrought methods. Powder metallurgy also enhances control over alloy composition and porosity, leading to optimized mechanical performance in aerospace, biomedical, and high-performance industrial applications.

Advantages of Wrought Titanium

Wrought titanium exhibits superior mechanical properties such as higher ductility, tensile strength, and fracture toughness compared to powder metallurgy titanium, making it ideal for aerospace and biomedical applications. The wrought process enhances grain refinement and alignment, resulting in improved fatigue resistance and structural integrity. Enhanced machinability and surface finish of wrought titanium also provide significant advantages for precision engineering.

Common Applications for Each Method

Powder metallurgy titanium is widely used in aerospace components, medical implants, and high-performance automotive parts due to its ability to form complex geometries with minimal material waste and superior mechanical properties. Wrought titanium is commonly employed in structural applications such as aircraft frames, marine hardware, and sports equipment, where high strength, ductility, and reliability are critical. Both methods leverage titanium's excellent corrosion resistance and biocompatibility, but powder metallurgy excels in precision manufacturing while wrought titanium suits large-scale forming processes.

Future Trends in Titanium Manufacturing

Powder metallurgy titanium offers enhanced material efficiency and the ability to produce complex geometries, aligning with future trends in lightweight aerospace and biomedical applications. Wrought titanium maintains advantages in high-strength structural components where precise mechanical properties and surface finishes are critical. Emerging innovations in additive manufacturing and hybrid processing are expected to integrate powder metallurgy and wrought titanium methods, driving sustainable and cost-effective production in the titanium industry.

Powder Metallurgy Titanium vs Wrought Titanium Infographic

materialdif.com

materialdif.com