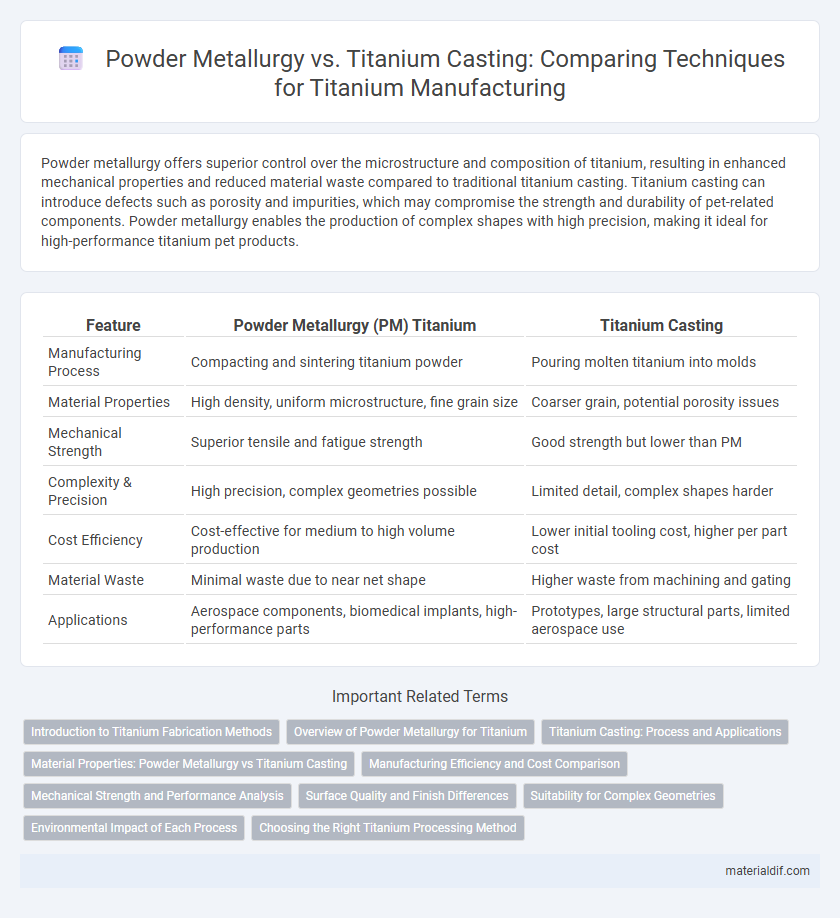

Powder metallurgy offers superior control over the microstructure and composition of titanium, resulting in enhanced mechanical properties and reduced material waste compared to traditional titanium casting. Titanium casting can introduce defects such as porosity and impurities, which may compromise the strength and durability of pet-related components. Powder metallurgy enables the production of complex shapes with high precision, making it ideal for high-performance titanium pet products.

Table of Comparison

| Feature | Powder Metallurgy (PM) Titanium | Titanium Casting |

|---|---|---|

| Manufacturing Process | Compacting and sintering titanium powder | Pouring molten titanium into molds |

| Material Properties | High density, uniform microstructure, fine grain size | Coarser grain, potential porosity issues |

| Mechanical Strength | Superior tensile and fatigue strength | Good strength but lower than PM |

| Complexity & Precision | High precision, complex geometries possible | Limited detail, complex shapes harder |

| Cost Efficiency | Cost-effective for medium to high volume production | Lower initial tooling cost, higher per part cost |

| Material Waste | Minimal waste due to near net shape | Higher waste from machining and gating |

| Applications | Aerospace components, biomedical implants, high-performance parts | Prototypes, large structural parts, limited aerospace use |

Introduction to Titanium Fabrication Methods

Titanium fabrication primarily involves powder metallurgy and casting, each offering distinct advantages for aerospace and medical applications. Powder metallurgy enables superior control over alloy composition and microstructure, resulting in enhanced strength and corrosion resistance through precise powder blending and sintering processes. Casting allows complex geometries by melting titanium alloy into molds, but challenges include controlling porosity and achieving uniform mechanical properties compared to powder metallurgy.

Overview of Powder Metallurgy for Titanium

Powder metallurgy for titanium involves producing titanium components through pressing and sintering fine titanium powders, enabling precise control over material properties and complex geometries. This process offers superior mechanical performance, such as enhanced strength and toughness, compared to conventional casting methods, while reducing material waste and allowing near-net shape manufacturing. Its ability to produce homogeneous microstructures makes powder metallurgy an ideal choice for aerospace, medical implants, and high-performance engineering applications.

Titanium Casting: Process and Applications

Titanium casting involves pouring molten titanium into molds to create complex shapes with high dimensional accuracy and superior mechanical properties, suitable for aerospace and biomedical implants. This process enables the production of intricate geometries that are difficult to achieve with powder metallurgy, offering enhanced fatigue resistance and corrosion resistance. Common applications of titanium casting include turbine blades, aircraft structural components, and custom medical devices where strength-to-weight ratio and biocompatibility are critical.

Material Properties: Powder Metallurgy vs Titanium Casting

Powder metallurgy titanium exhibits superior mechanical properties such as higher strength, enhanced fatigue resistance, and improved microstructural uniformity compared to titanium casting. The powder metallurgy process produces finer grain structures that contribute to better tensile strength and fracture toughness. In contrast, titanium casting often results in coarser grains and porosity, leading to reduced mechanical performance and increased risk of defects.

Manufacturing Efficiency and Cost Comparison

Powder metallurgy offers superior manufacturing efficiency for titanium by enabling near-net shape production, reducing material waste, and minimizing machining time compared to traditional titanium casting methods, which often involve longer cycle times and higher scrap rates due to melt-based processes. The cost comparison reveals that powder metallurgy generally has lower overall expenses for small to medium batch sizes, driven by reduced energy use and less post-processing, while titanium casting becomes more economical in large-scale production due to established mold reuse and economies of scale. Selecting between powder metallurgy and casting depends heavily on the complexity of titanium components and production volume, with powder metallurgy excelling in precision parts and casting favored for high-volume, less intricate shapes.

Mechanical Strength and Performance Analysis

Powder metallurgy Titanium exhibits superior mechanical strength and uniform microstructure compared to traditional casting, enhancing fatigue resistance and tensile properties. Titanium casting often results in coarser grain structures and potential porosity, leading to variable performance under load and reduced fracture toughness. Performance analysis consistently shows powder metallurgy Titanium components deliver higher reliability in aerospace and biomedical applications due to their enhanced structural integrity and durability.

Surface Quality and Finish Differences

Powder metallurgy produces titanium components with finer microstructures and superior surface quality compared to titanium casting, resulting in smoother finishes and reduced porosity. Titanium casting often exhibits coarser grain structures and higher surface roughness due to shrinkage and mold interactions, necessitating extensive post-processing for enhanced finish. The inherently precise control in powder metallurgy enables near-net-shape production, minimizing machining requirements and optimizing surface integrity for aerospace and biomedical applications.

Suitability for Complex Geometries

Powder metallurgy offers superior suitability for complex geometries in titanium components due to its ability to produce near-net shapes with high dimensional accuracy and minimal waste. Titanium casting can handle intricate designs but often faces challenges such as porosity and limited control over microstructure, affecting mechanical properties. Powder metallurgy enables the fabrication of titanium parts with fine detail and intricate internal features, making it ideal for aerospace and biomedical applications requiring precise and complex geometries.

Environmental Impact of Each Process

Powder metallurgy for titanium significantly reduces material waste and energy consumption compared to traditional titanium casting. The additive nature of powder metallurgy minimizes scrap and lowers greenhouse gas emissions during production. Titanium casting involves higher energy inputs and generates more industrial waste due to melting and mold processes, increasing its environmental footprint.

Choosing the Right Titanium Processing Method

Selecting the appropriate titanium processing method depends on the desired mechanical properties, complexity, and cost considerations of the final product. Powder metallurgy offers superior control over microstructure and allows for near-net shape manufacturing with minimal waste, making it ideal for high-strength, precision components. Titanium casting provides cost-effective solutions for larger, less intricate parts but may introduce porosity and inconsistent properties compared to powder metallurgy.

Powder Metallurgy vs Titanium Casting Infographic

materialdif.com

materialdif.com