Solid titanium offers superior strength, durability, and corrosion resistance compared to titanium composite materials, making it ideal for high-performance and long-lasting applications. Titanium composites blend titanium with other materials to reduce weight and cost but often sacrifice some mechanical properties and corrosion resistance. Choosing between solid titanium and titanium composite depends on the specific requirements for strength, weight, and budget in pet-related products.

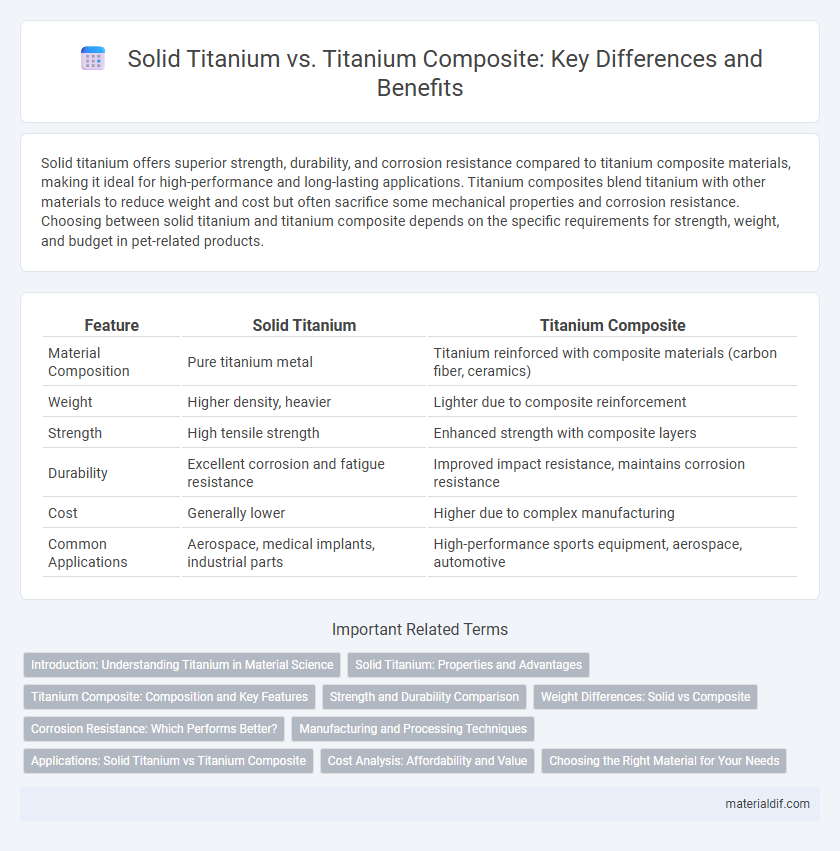

Table of Comparison

| Feature | Solid Titanium | Titanium Composite |

|---|---|---|

| Material Composition | Pure titanium metal | Titanium reinforced with composite materials (carbon fiber, ceramics) |

| Weight | Higher density, heavier | Lighter due to composite reinforcement |

| Strength | High tensile strength | Enhanced strength with composite layers |

| Durability | Excellent corrosion and fatigue resistance | Improved impact resistance, maintains corrosion resistance |

| Cost | Generally lower | Higher due to complex manufacturing |

| Common Applications | Aerospace, medical implants, industrial parts | High-performance sports equipment, aerospace, automotive |

Introduction: Understanding Titanium in Material Science

Solid titanium boasts exceptional strength, corrosion resistance, and biocompatibility, making it a preferred choice in aerospace, medical implants, and industrial applications. Titanium composites combine titanium with other materials like carbon fibers or ceramics to enhance specific properties such as stiffness, lightweight performance, and thermal stability. Understanding the differences between solid titanium and titanium composites is crucial for selecting the right material based on application requirements and performance criteria.

Solid Titanium: Properties and Advantages

Solid titanium boasts exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for aerospace, medical implants, and industrial applications. Its homogeneous metallic structure ensures consistent mechanical properties, superior durability, and ease of fabrication compared to titanium composites. Solid titanium also offers excellent thermal stability and fatigue resistance, enhancing long-term performance in demanding environments.

Titanium Composite: Composition and Key Features

Titanium composites consist of a titanium matrix reinforced with materials like carbon fibers or ceramic particles, enhancing strength, stiffness, and wear resistance compared to solid titanium. These composites offer improved fatigue resistance and reduced weight, making them ideal for aerospace, automotive, and biomedical applications. The integration of reinforcement materials creates a tailored balance of mechanical properties while maintaining titanium's corrosion resistance and biocompatibility.

Strength and Durability Comparison

Solid titanium offers exceptional strength and superior corrosion resistance, making it highly durable under extreme conditions. Titanium composites combine titanium with other materials to enhance specific properties like weight reduction and impact resistance while maintaining substantial strength. In applications requiring maximum durability and structural integrity, solid titanium typically outperforms composites, though composites provide a favorable balance for weight-sensitive uses.

Weight Differences: Solid vs Composite

Solid titanium exhibits higher density, typically around 4.5 g/cm3, making it significantly heavier than titanium composites, which combine titanium with lighter materials like carbon fiber or aluminum to reduce overall weight. Titanium composites can achieve weight reductions of up to 30-50% compared to solid titanium while maintaining comparable strength and durability. These weight savings enhance applications in aerospace, automotive, and sporting goods where reducing mass without sacrificing performance is critical.

Corrosion Resistance: Which Performs Better?

Solid titanium exhibits exceptional corrosion resistance due to its homogeneous microstructure and protective oxide layer, making it highly durable in harsh environments. Titanium composites, while engineered for enhanced strength and weight reduction, may have varied corrosion resistance depending on the matrix and reinforcement materials used. Solid titanium generally outperforms titanium composites in corrosion resistance, particularly in aggressive chemical and marine conditions.

Manufacturing and Processing Techniques

Solid titanium is typically produced through methods like vacuum arc remelting (VAR) and electron beam melting (EBM), requiring precise temperature control to ensure high purity and uniform grain structure. Titanium composites combine titanium with reinforcing materials such as carbon fibers or ceramics, utilizing advanced powder metallurgy and hot isostatic pressing (HIP) techniques to achieve enhanced strength-to-weight ratios and improved fatigue resistance. Processing titanium composites demands specialized equipment for matrix infiltration and curing, which differs significantly from the machining and forging processes used for solid titanium components.

Applications: Solid Titanium vs Titanium Composite

Solid titanium is favored in aerospace and medical implants due to its exceptional strength, corrosion resistance, and biocompatibility, ensuring reliability in critical structural components and prosthetics. Titanium composites combine titanium with reinforcing fibers or ceramics, enhancing stiffness and reducing weight, making them ideal for high-performance automotive parts and sporting equipment where lightweight durability is crucial. The application choice depends on balancing mechanical properties and cost-efficiency, with solid titanium excelling in durability and composites offering optimized strength-to-weight ratios.

Cost Analysis: Affordability and Value

Solid titanium offers exceptional strength and corrosion resistance but comes with a higher price due to raw material costs and machining complexity. Titanium composites, combining titanium with carbon fiber or ceramic, reduce weight and manufacturing expenses while maintaining structural integrity, providing a cost-effective alternative for aerospace and automotive industries. Evaluating total lifecycle costs, including maintenance and performance, reveals titanium composites as a valuable investment where weight savings and affordability drive design decisions.

Choosing the Right Material for Your Needs

Solid titanium offers exceptional strength, corrosion resistance, and biocompatibility, making it ideal for high-performance applications such as aerospace and medical implants. Titanium composites combine titanium with other materials to reduce weight while maintaining sufficient durability, suitable for automotive and sports equipment where lightweight and flexibility are critical. Selecting between solid titanium and titanium composites depends on balancing factors like mechanical strength requirements, weight constraints, and cost efficiency for your specific project.

Solid Titanium vs Titanium Composite Infographic

materialdif.com

materialdif.com