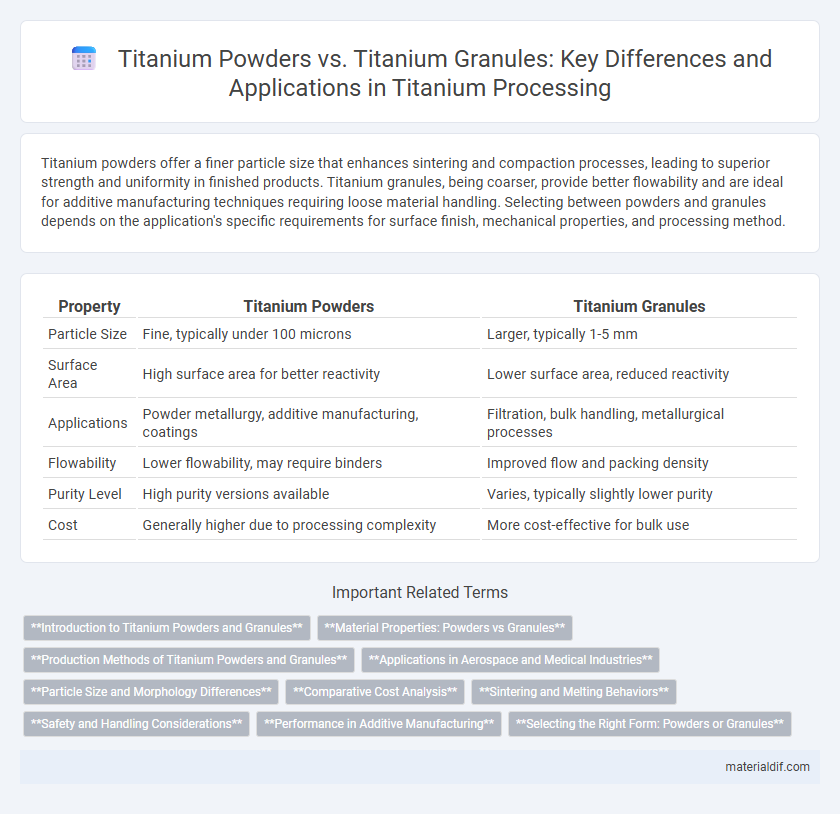

Titanium powders offer a finer particle size that enhances sintering and compaction processes, leading to superior strength and uniformity in finished products. Titanium granules, being coarser, provide better flowability and are ideal for additive manufacturing techniques requiring loose material handling. Selecting between powders and granules depends on the application's specific requirements for surface finish, mechanical properties, and processing method.

Table of Comparison

| Property | Titanium Powders | Titanium Granules |

|---|---|---|

| Particle Size | Fine, typically under 100 microns | Larger, typically 1-5 mm |

| Surface Area | High surface area for better reactivity | Lower surface area, reduced reactivity |

| Applications | Powder metallurgy, additive manufacturing, coatings | Filtration, bulk handling, metallurgical processes |

| Flowability | Lower flowability, may require binders | Improved flow and packing density |

| Purity Level | High purity versions available | Varies, typically slightly lower purity |

| Cost | Generally higher due to processing complexity | More cost-effective for bulk use |

Introduction to Titanium Powders and Granules

Titanium powders consist of fine particles typically less than 150 microns, offering high surface area and reactivity used extensively in additive manufacturing and powder metallurgy. Titanium granules are coarser aggregates, generally between 150 to 3000 microns, valued for ease of handling and consistent flow characteristics in processes like sintering and chemical vapor deposition. Understanding the distinctions in particle size and morphology between titanium powders and granules is essential for optimizing their use in aerospace, biomedical implants, and chemical applications.

Material Properties: Powders vs Granules

Titanium powders exhibit higher surface area and enhanced reactivity compared to titanium granules, making them ideal for additive manufacturing and powder metallurgy applications. In contrast, titanium granules feature larger particle sizes, offering improved flowability and reduced oxidation sensitivity, which benefits processes like casting and sintering. The distinct morphology and particle size distribution directly influence the mechanical properties and thermal behavior in titanium-based material processing.

Production Methods of Titanium Powders and Granules

Titanium powders are primarily produced through methods such as atomization, including gas and plasma atomization, which yield fine, spherical particles ideal for additive manufacturing and powder metallurgy. In contrast, titanium granules are typically manufactured by crushing and milling larger titanium pieces, resulting in coarser particles used mainly for metallurgical applications and sintering processes. The choice of production method directly influences particle size, morphology, and purity, which are critical parameters for end-use performance in aerospace, medical implants, and industrial components.

Applications in Aerospace and Medical Industries

Titanium powders are extensively used in aerospace and medical industries due to their superior ability to produce complex shapes through additive manufacturing, enhancing fuel efficiency and implant biocompatibility. Titanium granules, preferred in traditional manufacturing, enable the production of large, structural aerospace components and orthopedic implants with high strength and durability. Both forms provide critical materials for aerospace engines and medical devices, optimizing performance and patient outcomes.

Particle Size and Morphology Differences

Titanium powders typically feature fine, uniformly sized particles with spherical or near-spherical morphology, enhancing flowability and packing density for additive manufacturing and powder metallurgy applications. In contrast, titanium granules exhibit larger, irregularly shaped particles, often resulting from mechanical granulation processes, which can affect surface area and compaction behavior. These distinctions in particle size and morphology directly influence the material's sintering, mechanical properties, and overall performance in industrial uses.

Comparative Cost Analysis

Titanium powders generally incur higher production costs due to more complex atomization processes and stringent quality control requirements compared to titanium granules. Granules offer cost advantages by utilizing simpler manufacturing techniques and lower material handling expenses, making them more economical for bulk applications. The price differential often influences selection based on budget constraints and desired material properties in aerospace and biomedical industries.

Sintering and Melting Behaviors

Titanium powders exhibit superior sintering behavior due to their high surface area and fine particle size, enabling lower sintering temperatures and enhanced densification compared to titanium granules. Granules, characterized by larger particle size and reduced surface area, require higher temperatures for effective melting and sintering, often resulting in less uniform microstructures. The melting point of titanium remains consistent across both forms, but powders facilitate more efficient thermal diffusion during sintering processes.

Safety and Handling Considerations

Titanium powders present higher safety risks compared to titanium granules due to their increased surface area and finer particle size, which elevate the potential for dust explosions and respiratory hazards. Proper handling protocols for titanium powders require using inert atmospheres, explosion-proof equipment, and personal protective equipment (PPE) to mitigate fire and inhalation dangers. In contrast, titanium granules possess lower dustiness and reduced reactivity, allowing for safer storage and handling with standard industrial precautions.

Performance in Additive Manufacturing

Titanium powders exhibit superior flowability and packing density, which enhance precision and consistency in additive manufacturing processes such as selective laser melting. In contrast, titanium granules often require additional processing to achieve comparable particle size distribution, impacting layer uniformity and mechanical properties. The finer particle size of titanium powders enables better energy absorption and melting behavior, resulting in higher-quality, defect-free components.

Selecting the Right Form: Powders or Granules

Selecting the right titanium form depends on the intended application and processing method; titanium powders offer higher surface area and reactivity, ideal for additive manufacturing and sintering processes. Titanium granules provide better flowability and are preferred for melting, casting, or powder metallurgy where uniform packing density is critical. Understanding the differences in particle size, morphology, and packing behavior ensures optimized mechanical properties and processing efficiency in aerospace, medical implants, and chemical industries.

Titanium Powders vs Titanium Granules Infographic

materialdif.com

materialdif.com