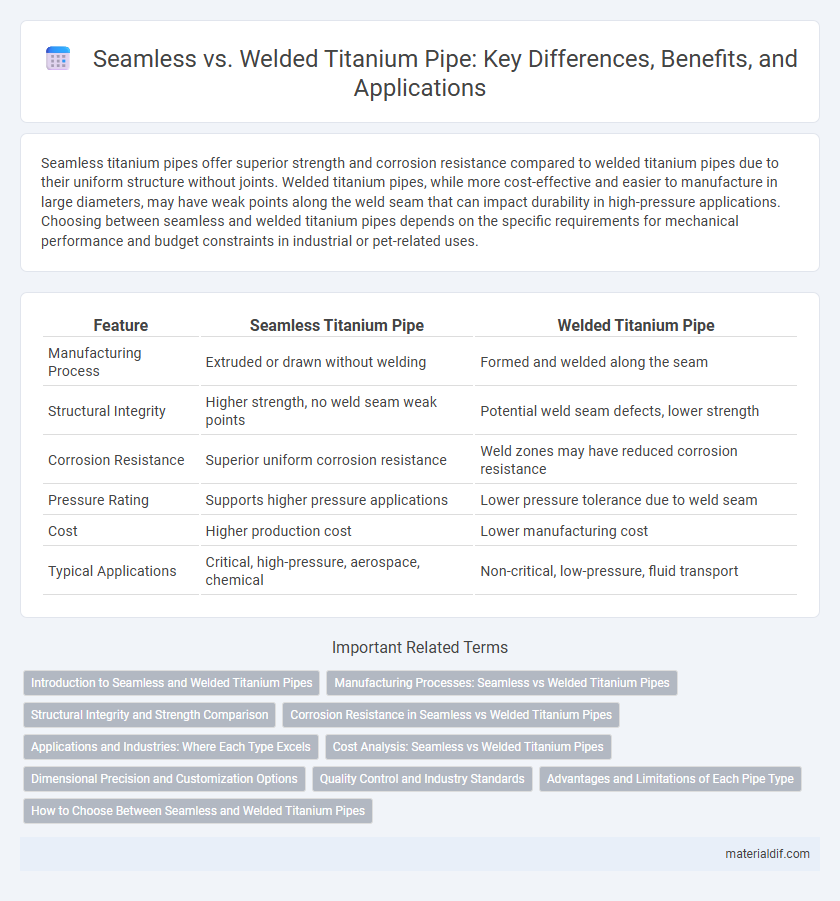

Seamless titanium pipes offer superior strength and corrosion resistance compared to welded titanium pipes due to their uniform structure without joints. Welded titanium pipes, while more cost-effective and easier to manufacture in large diameters, may have weak points along the weld seam that can impact durability in high-pressure applications. Choosing between seamless and welded titanium pipes depends on the specific requirements for mechanical performance and budget constraints in industrial or pet-related uses.

Table of Comparison

| Feature | Seamless Titanium Pipe | Welded Titanium Pipe |

|---|---|---|

| Manufacturing Process | Extruded or drawn without welding | Formed and welded along the seam |

| Structural Integrity | Higher strength, no weld seam weak points | Potential weld seam defects, lower strength |

| Corrosion Resistance | Superior uniform corrosion resistance | Weld zones may have reduced corrosion resistance |

| Pressure Rating | Supports higher pressure applications | Lower pressure tolerance due to weld seam |

| Cost | Higher production cost | Lower manufacturing cost |

| Typical Applications | Critical, high-pressure, aerospace, chemical | Non-critical, low-pressure, fluid transport |

Introduction to Seamless and Welded Titanium Pipes

Seamless titanium pipes are manufactured through a hot extrusion or rotary piercing process, creating a uniform, joint-free tube ideal for high-pressure applications and corrosive environments. Welded titanium pipes are produced by rolling or bending titanium sheets into shape and joining the seam through welding, offering cost-effective solutions for larger diameters and less demanding conditions. Both types provide excellent corrosion resistance and strength, but selection depends on application-specific pressure requirements and fabrication complexity.

Manufacturing Processes: Seamless vs Welded Titanium Pipes

Seamless titanium pipes are manufactured through a hot extrusion or rotary piercing process, resulting in a single, continuous metal structure without joints, which enhances their strength and resistance to high pressure. Welded titanium pipes are produced by rolling titanium plates or strips and then welding the edges together, which may introduce potential weak points along the weld seam despite advanced welding techniques. The manufacturing process differences directly impact the mechanical properties, corrosion resistance, and suitability of titanium pipes for critical applications in aerospace, chemical processing, and marine industries.

Structural Integrity and Strength Comparison

Seamless titanium pipes exhibit superior structural integrity due to the absence of weld joints, minimizing stress concentration points and potential failure risks under high-pressure applications. Welded titanium pipes, while often more cost-effective and readily available in larger diameters, may present vulnerabilities at the weld seams, impacting overall strength and durability. In critical environments such as aerospace or chemical processing, seamless titanium pipes are preferred for their enhanced resistance to fatigue and corrosion-related degradation.

Corrosion Resistance in Seamless vs Welded Titanium Pipes

Seamless titanium pipes exhibit superior corrosion resistance due to the absence of welded joints, which can act as potential sites for corrosion initiation and stress concentration. In contrast, welded titanium pipes may have heat-affected zones around the welds that are more susceptible to corrosion, especially in aggressive environments involving chlorides or acidic media. This inherent advantage makes seamless titanium pipes ideal for highly corrosive applications in chemical processing and marine industries.

Applications and Industries: Where Each Type Excels

Seamless titanium pipes excel in aerospace, chemical, and marine industries due to their superior strength, corrosion resistance, and ability to withstand high pressure and temperature conditions without welding seams. Welded titanium pipes find extensive use in oil and gas, power generation, and pharmaceutical sectors where cost-efficiency and custom dimensions are critical, with weld zones designed to meet specific mechanical and environmental requirements. Both pipe types serve critical roles in water treatment and desalination plants, choosing seamless or welded titanium based on operational stress and fluid type.

Cost Analysis: Seamless vs Welded Titanium Pipes

Seamless titanium pipes generally have a higher upfront cost due to complex manufacturing processes and the use of expensive raw titanium billets. Welded titanium pipes are more cost-effective as they involve lower production expenses, utilizing titanium strips or plates joined through welding techniques. Long-term cost analysis must also consider factors like durability, performance under stress, and maintenance, where seamless pipes often offer better value despite initial higher investment.

Dimensional Precision and Customization Options

Seamless titanium pipes offer superior dimensional precision due to their manufacturing process, which eliminates weld seams and reduces variability in wall thickness and diameter. Welded titanium pipes provide greater customization options, allowing for tailored dimensions and designs to accommodate specific project requirements. Both types maintain high corrosion resistance and strength, but seamless pipes excel in applications demanding stringent tolerances and uniformity.

Quality Control and Industry Standards

Seamless titanium pipes offer superior quality control due to their uniform structure and absence of weld seams, reducing potential weak points and enhancing corrosion resistance in critical applications. Welded titanium pipes undergo rigorous inspection processes, including radiographic and ultrasonic testing, to ensure weld integrity meets ASTM B861 and ASME B31.3 industry standards. Both types must comply with strict specifications for material composition and mechanical properties to guarantee performance in aerospace, chemical processing, and marine industries.

Advantages and Limitations of Each Pipe Type

Seamless titanium pipes offer superior strength, corrosion resistance, and uniformity, making them ideal for high-pressure and critical applications such as aerospace and chemical processing. Welded titanium pipes provide cost-effectiveness and the ability to produce larger diameters with customized lengths but may have slightly reduced mechanical properties at the weld joints, affecting performance under extreme stress. Both types exhibit excellent corrosion resistance, yet seamless pipes are preferred for demanding environments due to their homogeneous structure and absence of weld defects.

How to Choose Between Seamless and Welded Titanium Pipes

Choosing between seamless and welded titanium pipes depends on the application's pressure requirements and corrosion resistance needs. Seamless titanium pipes offer superior strength and uniformity, making them ideal for high-pressure environments and critical aerospace or chemical processing applications. Welded titanium pipes are more cost-effective and suitable for low to moderate pressure uses where corrosion resistance is still essential but exact internal surface quality is less critical.

Seamless Titanium Pipe vs Welded Titanium Pipe Infographic

materialdif.com

materialdif.com