Titanium alloy offers enhanced strength and durability compared to pure titanium, making it ideal for applications requiring high mechanical performance. While pure titanium boasts superior corrosion resistance and biocompatibility, titanium alloys are engineered to provide a balance between lightweight properties and structural integrity. Selecting between titanium alloy and pure titanium depends on the specific needs for strength, corrosion resistance, and weight in pet-related products.

Table of Comparison

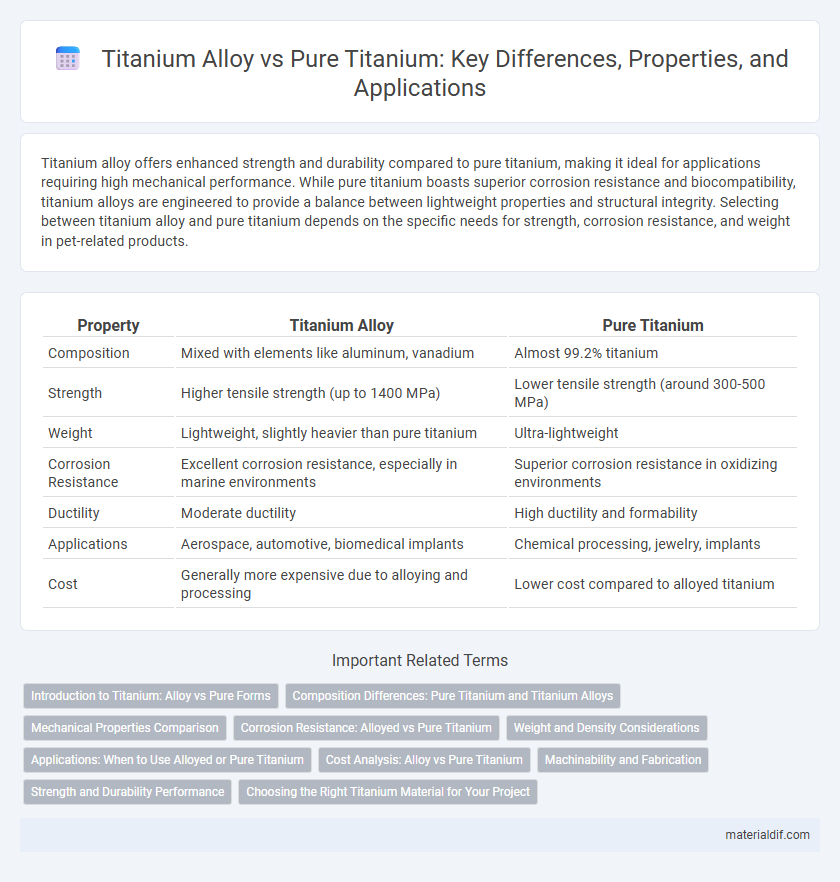

| Property | Titanium Alloy | Pure Titanium |

|---|---|---|

| Composition | Mixed with elements like aluminum, vanadium | Almost 99.2% titanium |

| Strength | Higher tensile strength (up to 1400 MPa) | Lower tensile strength (around 300-500 MPa) |

| Weight | Lightweight, slightly heavier than pure titanium | Ultra-lightweight |

| Corrosion Resistance | Excellent corrosion resistance, especially in marine environments | Superior corrosion resistance in oxidizing environments |

| Ductility | Moderate ductility | High ductility and formability |

| Applications | Aerospace, automotive, biomedical implants | Chemical processing, jewelry, implants |

| Cost | Generally more expensive due to alloying and processing | Lower cost compared to alloyed titanium |

Introduction to Titanium: Alloy vs Pure Forms

Titanium alloys consist of titanium combined with elements such as aluminum, vanadium, or molybdenum, enhancing strength, corrosion resistance, and heat tolerance compared to pure titanium. Pure titanium, also known as commercially pure (CP) titanium, offers excellent corrosion resistance and biocompatibility but has lower mechanical strength. These differences make titanium alloys ideal for aerospace and medical implants, while pure titanium suits chemical processing and marine applications.

Composition Differences: Pure Titanium and Titanium Alloys

Pure titanium consists almost entirely of titanium with minimal impurities, offering excellent corrosion resistance and high strength-to-weight ratio. Titanium alloys incorporate elements like aluminum, vanadium, molybdenum, or iron to enhance mechanical properties, including improved strength, hardness, and temperature resistance. These composition differences make titanium alloys more suitable for aerospace, medical implants, and industrial applications requiring superior durability compared to pure titanium.

Mechanical Properties Comparison

Titanium alloy exhibits superior mechanical properties compared to pure titanium, featuring higher tensile strength and improved hardness due to the addition of elements like aluminum and vanadium. The alloy's enhanced fatigue resistance and better wear properties make it suitable for demanding aerospace and biomedical applications. Pure titanium, while more corrosion-resistant and ductile, generally lacks the strength and durability required for high-stress environments.

Corrosion Resistance: Alloyed vs Pure Titanium

Titanium alloys generally exhibit enhanced mechanical properties compared to pure titanium but may present slightly varied corrosion resistance depending on the alloying elements used. Pure titanium offers exceptional corrosion resistance in most environments due to its stable oxide layer, making it highly resistant to oxidation, seawater, and acidic conditions. Some titanium alloys maintain similar corrosion resistance, particularly those alloyed with palladium or molybdenum, which enhance resistance to chloride-induced corrosion, while others may be more susceptible in certain aggressive environments.

Weight and Density Considerations

Titanium alloys typically exhibit higher strength-to-weight ratios compared to pure titanium, making them ideal for applications requiring enhanced mechanical performance without significant weight increase. Pure titanium has a density of approximately 4.51 g/cm3, while common titanium alloys, such as Ti-6Al-4V, have slightly higher densities around 4.43 to 4.48 g/cm3 but offer superior strength. The marginal difference in density often results in lighter components with titanium alloys, optimizing durability and weight in aerospace and automotive industries.

Applications: When to Use Alloyed or Pure Titanium

Titanium alloys offer superior strength, corrosion resistance, and wear resistance, making them ideal for aerospace, military, and automotive applications that require high performance and durability. Pure titanium excels in biomedical implants and chemical processing equipment due to its excellent biocompatibility and resistance to corrosion in aggressive environments. Selecting between titanium alloy and pure titanium depends on the specific application demands, balancing strength, corrosion resistance, and biocompatibility.

Cost Analysis: Alloy vs Pure Titanium

Titanium alloys generally offer superior strength and corrosion resistance compared to pure titanium, but they come at a higher production cost due to complex alloying and processing techniques. Pure titanium is less expensive and easier to fabricate, making it suitable for applications where cost efficiency outweighs the need for enhanced mechanical properties. Analyzing total lifecycle expenses reveals that although titanium alloys have a higher upfront cost, their durability and performance often reduce maintenance and replacement expenditures over time.

Machinability and Fabrication

Titanium alloys typically exhibit improved machinability compared to pure titanium due to the addition of elements such as aluminum and vanadium, which enhance strength and reduce ductility, allowing more precise and efficient fabrication processes. Pure titanium, while highly corrosion-resistant and biocompatible, tends to be more challenging to machine because of its lower thermal conductivity and higher chemical reactivity, leading to rapid tool wear and slower cutting speeds. Fabrication of titanium alloys generally benefits from advanced machining techniques like CNC and EDM, optimizing productivity while maintaining the material's excellent strength-to-weight ratio.

Strength and Durability Performance

Titanium alloys exhibit significantly higher strength and improved durability compared to pure titanium, making them ideal for aerospace, automotive, and medical applications. Alloying elements such as aluminum and vanadium enhance tensile strength and fatigue resistance while maintaining corrosion resistance and lightweight properties. Pure titanium offers excellent biocompatibility and corrosion resistance but has lower mechanical strength, limiting its use in high-stress environments.

Choosing the Right Titanium Material for Your Project

Titanium alloys offer enhanced strength, corrosion resistance, and durability compared to pure titanium, making them ideal for high-stress applications in aerospace, automotive, and medical industries. Pure titanium provides superior biocompatibility and corrosion resistance, suitable for implants and chemical processing equipment where contamination is critical. Selecting the right titanium material depends on balancing mechanical properties, environmental factors, and budget constraints specific to your project's requirements.

Titanium Alloy vs Pure Titanium Infographic

materialdif.com

materialdif.com