Commercially Pure Titanium offers excellent corrosion resistance and biocompatibility, making it ideal for pet accessories that require durability and safety. Alloyed Titanium provides increased strength and hardness through the addition of elements like aluminum and vanadium, suitable for applications demanding enhanced performance. Choosing between commercially pure and alloyed titanium depends on the specific balance needed between flexibility and structural integrity for pet products.

Table of Comparison

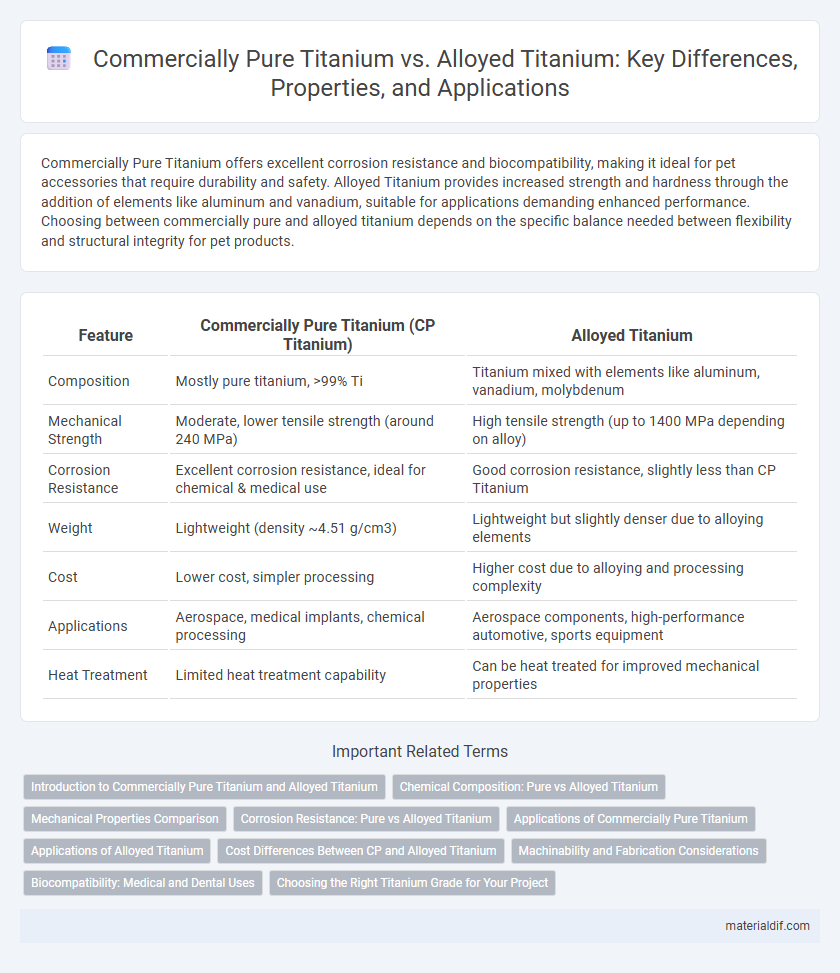

| Feature | Commercially Pure Titanium (CP Titanium) | Alloyed Titanium |

|---|---|---|

| Composition | Mostly pure titanium, >99% Ti | Titanium mixed with elements like aluminum, vanadium, molybdenum |

| Mechanical Strength | Moderate, lower tensile strength (around 240 MPa) | High tensile strength (up to 1400 MPa depending on alloy) |

| Corrosion Resistance | Excellent corrosion resistance, ideal for chemical & medical use | Good corrosion resistance, slightly less than CP Titanium |

| Weight | Lightweight (density ~4.51 g/cm3) | Lightweight but slightly denser due to alloying elements |

| Cost | Lower cost, simpler processing | Higher cost due to alloying and processing complexity |

| Applications | Aerospace, medical implants, chemical processing | Aerospace components, high-performance automotive, sports equipment |

| Heat Treatment | Limited heat treatment capability | Can be heat treated for improved mechanical properties |

Introduction to Commercially Pure Titanium and Alloyed Titanium

Commercially pure titanium consists of unalloyed titanium with a minimum of 99% titanium content, known for its excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility, making it ideal for medical implants and aerospace applications. Alloyed titanium combines titanium with elements such as aluminum, vanadium, and molybdenum, significantly enhancing mechanical properties like strength, toughness, and temperature resistance for demanding structural and industrial uses. The selection between commercially pure and alloyed titanium depends on performance requirements, environmental conditions, and cost considerations within specific engineering or manufacturing contexts.

Chemical Composition: Pure vs Alloyed Titanium

Commercially pure titanium primarily consists of over 99% titanium, with minimal impurities such as iron, oxygen, and carbon, ensuring excellent corrosion resistance and biocompatibility. Alloyed titanium incorporates elements like aluminum, vanadium, molybdenum, and iron, enhancing mechanical strength, hardness, and fatigue resistance for demanding engineering applications. The specific chemical composition variations directly impact properties like tensile strength, ductility, and corrosion behavior in different industrial uses.

Mechanical Properties Comparison

Commercially pure titanium exhibits excellent corrosion resistance and high ductility but has lower tensile strength and hardness compared to alloyed titanium. Alloyed titanium, typically combined with elements such as aluminum and vanadium, delivers significantly enhanced mechanical properties, including increased yield strength, tensile strength, and fatigue resistance. These improvements make alloyed titanium ideal for aerospace, automotive, and biomedical applications requiring superior load-bearing capacity and durability.

Corrosion Resistance: Pure vs Alloyed Titanium

Commercially pure titanium exhibits exceptional corrosion resistance in various environments due to its stable oxide layer, making it highly suitable for medical implants and chemical processing equipment. Alloyed titanium, while offering enhanced mechanical strength, may have slightly reduced corrosion resistance depending on the alloying elements such as aluminum, vanadium, or molybdenum. The balance between corrosion resistance and mechanical properties in titanium alloys is critical for applications requiring both durability and resistance to harsh chemical or marine conditions.

Applications of Commercially Pure Titanium

Commercially pure titanium is widely used in aerospace, medical, and chemical processing industries due to its excellent corrosion resistance, biocompatibility, and high strength-to-weight ratio. Unlike alloyed titanium, which is enhanced with elements like aluminum and vanadium for higher strength, commercially pure titanium offers superior corrosion resistance in marine and aggressive chemical environments. Its applications include surgical implants, heat exchangers, and desalination plants where material purity and longevity are critical.

Applications of Alloyed Titanium

Alloyed titanium offers enhanced strength, corrosion resistance, and temperature tolerance, making it ideal for demanding aerospace components, automotive parts, and medical implants. Its ability to withstand extreme environments extends to chemical processing equipment and marine applications, where durability and lightweight properties are crucial. Alloyed titanium's versatility supports high-performance engineering solutions across various industries requiring superior mechanical and thermal performance.

Cost Differences Between CP and Alloyed Titanium

Commercially Pure (CP) Titanium typically costs less than alloyed titanium due to its simpler composition and easier processing requirements. Alloyed titanium, which contains elements such as aluminum, vanadium, or molybdenum, incurs higher costs because of additional raw materials and more complex manufacturing processes. The price difference reflects the enhanced mechanical properties and corrosion resistance provided by alloying elements, making alloyed titanium more suitable for demanding industrial applications despite its higher expense.

Machinability and Fabrication Considerations

Commercially Pure Titanium offers superior corrosion resistance and excellent weldability but has lower strength and machinability compared to Alloyed Titanium. Alloyed Titanium, such as Grade 5 (Ti-6Al-4V), provides higher strength and enhanced mechanical properties, resulting in increased tool wear and more challenging machining processes. Fabrication considerations must balance machinability with performance requirements, where Commercially Pure Titanium suits complex forming and welding, while Alloyed Titanium demands specialized tooling and parameter optimization for efficient machining.

Biocompatibility: Medical and Dental Uses

Commercially pure titanium exhibits superior biocompatibility due to its minimal alloying elements, making it the preferred choice for dental implants and orthopedic devices where tissue integration and reduced allergic reactions are critical. Alloyed titanium, such as Ti-6Al-4V, offers enhanced mechanical strength but may introduce trace elements that can affect cellular response and long-term implant stability. Medical-grade commercially pure titanium grades 1 to 4 balance corrosion resistance and biocompatibility, ensuring safe and durable applications in surgical implants and prosthetics.

Choosing the Right Titanium Grade for Your Project

Commercially Pure Titanium offers excellent corrosion resistance and biocompatibility, making it ideal for medical implants and chemical processing equipment, whereas Alloyed Titanium grades provide enhanced strength and durability suitable for aerospace and automotive applications. Selecting the right titanium grade depends on project-specific requirements such as mechanical performance, environmental exposure, and budget constraints. Understanding the differences between Grade 1-4 commercially pure titanium and alloyed grades like Ti-6Al-4V ensures optimal material performance and cost-efficiency.

Commercially Pure Titanium vs Alloyed Titanium Infographic

materialdif.com

materialdif.com