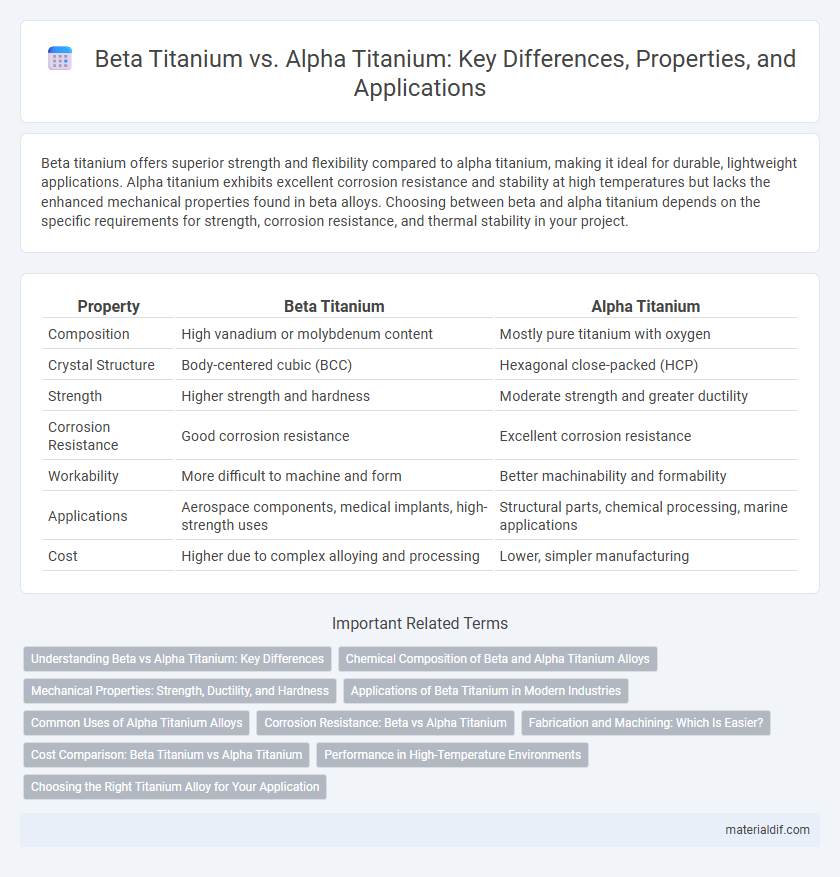

Beta titanium offers superior strength and flexibility compared to alpha titanium, making it ideal for durable, lightweight applications. Alpha titanium exhibits excellent corrosion resistance and stability at high temperatures but lacks the enhanced mechanical properties found in beta alloys. Choosing between beta and alpha titanium depends on the specific requirements for strength, corrosion resistance, and thermal stability in your project.

Table of Comparison

| Property | Beta Titanium | Alpha Titanium |

|---|---|---|

| Composition | High vanadium or molybdenum content | Mostly pure titanium with oxygen |

| Crystal Structure | Body-centered cubic (BCC) | Hexagonal close-packed (HCP) |

| Strength | Higher strength and hardness | Moderate strength and greater ductility |

| Corrosion Resistance | Good corrosion resistance | Excellent corrosion resistance |

| Workability | More difficult to machine and form | Better machinability and formability |

| Applications | Aerospace components, medical implants, high-strength uses | Structural parts, chemical processing, marine applications |

| Cost | Higher due to complex alloying and processing | Lower, simpler manufacturing |

Understanding Beta vs Alpha Titanium: Key Differences

Beta titanium alloys exhibit higher strength and excellent corrosion resistance compared to alpha titanium, making them suitable for aerospace and biomedical applications requiring durability. Alpha titanium is more stable at room temperature and offers superior weldability and toughness, which is advantageous for chemical processing and marine environments. The microstructure differences, with beta phases stabilized by elements like vanadium and molybdenum, result in distinct mechanical properties and heat treatment responses between beta and alpha titanium alloys.

Chemical Composition of Beta and Alpha Titanium Alloys

Beta titanium alloys primarily contain elements such as molybdenum, vanadium, and niobium, which stabilize the beta phase and enhance strength and corrosion resistance. Alpha titanium alloys are enriched with aluminum and oxygen, providing improved creep resistance and excellent weldability. The distinct chemical compositions of these alloys influence their microstructure and mechanical properties, making beta alloys suitable for high-strength applications and alpha alloys ideal for aerospace components.

Mechanical Properties: Strength, Ductility, and Hardness

Beta titanium alloys exhibit higher strength and hardness compared to alpha titanium due to their body-centered cubic (BCC) crystal structure, which allows for enhanced mechanical performance under stress. Alpha titanium, characterized by a hexagonal close-packed (HCP) structure, offers superior ductility and better resistance to creep at elevated temperatures. The balance between strength and ductility in beta titanium makes it ideal for aerospace and biomedical applications requiring robust and durable materials.

Applications of Beta Titanium in Modern Industries

Beta titanium alloys exhibit superior strength, corrosion resistance, and excellent formability, making them ideal for aerospace components, medical implants, and automotive parts. Their ability to be heat treated for enhanced mechanical properties allows for lightweight yet durable structures in modern engineering. Industries rely on beta titanium for high-performance applications requiring toughness and fatigue resistance under extreme conditions.

Common Uses of Alpha Titanium Alloys

Alpha titanium alloys are widely used in aerospace applications due to their excellent corrosion resistance and good weldability, making them ideal for aircraft engine components and structural parts. These alloys offer high strength and stability at elevated temperatures, which suits them for chemical processing equipment and marine environments. Their non-magnetic properties also lend well to medical implants and precision instruments.

Corrosion Resistance: Beta vs Alpha Titanium

Beta titanium alloys exhibit superior corrosion resistance compared to alpha titanium, especially in chloride-containing environments, due to their stabilized microstructure with elements like molybdenum and vanadium. Alpha titanium provides excellent corrosion resistance in oxidizing environments but tends to be less effective in reducing or acidic conditions where beta titanium outperforms. The enhanced resistance of beta titanium alloys makes them ideal for marine and chemical processing applications requiring prolonged exposure to aggressive agents.

Fabrication and Machining: Which Is Easier?

Beta titanium alloys exhibit superior machinability compared to alpha titanium due to their lower strength and higher ductility at room temperature, facilitating easier cutting and shaping processes. Alpha titanium's higher strength and lower ductility increase tool wear and require slower machining speeds, making fabrication more challenging. Manufacturers often prefer beta titanium in applications demanding intricate machining and complex geometries, optimizing production efficiency and cost.

Cost Comparison: Beta Titanium vs Alpha Titanium

Beta titanium alloys generally cost more than alpha titanium alloys due to their complex alloying elements and advanced heat treatment requirements. Alpha titanium is cheaper to produce, benefiting from simpler processing and lower alloy content. The price disparity influences their selection in industries prioritizing either cost-efficiency or superior mechanical properties.

Performance in High-Temperature Environments

Beta titanium alloys exhibit superior performance in high-temperature environments compared to alpha titanium, maintaining strength and corrosion resistance at temperatures above 600degC (1112degF). Alpha titanium alloys typically lose mechanical properties when exposed to elevated temperatures exceeding 400degC (752degF) due to phase instability. This makes beta titanium ideal for aerospace and automotive components requiring durability under thermal stress.

Choosing the Right Titanium Alloy for Your Application

Beta titanium alloys offer higher strength and improved corrosion resistance compared to alpha titanium, making them ideal for aerospace and biomedical implants requiring durability and toughness. Alpha titanium alloys exhibit excellent weldability and good corrosion resistance, suitable for applications like chemical processing and marine environments where formability is crucial. Selecting the right titanium alloy depends on balancing mechanical properties, corrosion resistance, and manufacturing needs tailored to the specific industrial application.

Beta Titanium vs Alpha Titanium Infographic

materialdif.com

materialdif.com