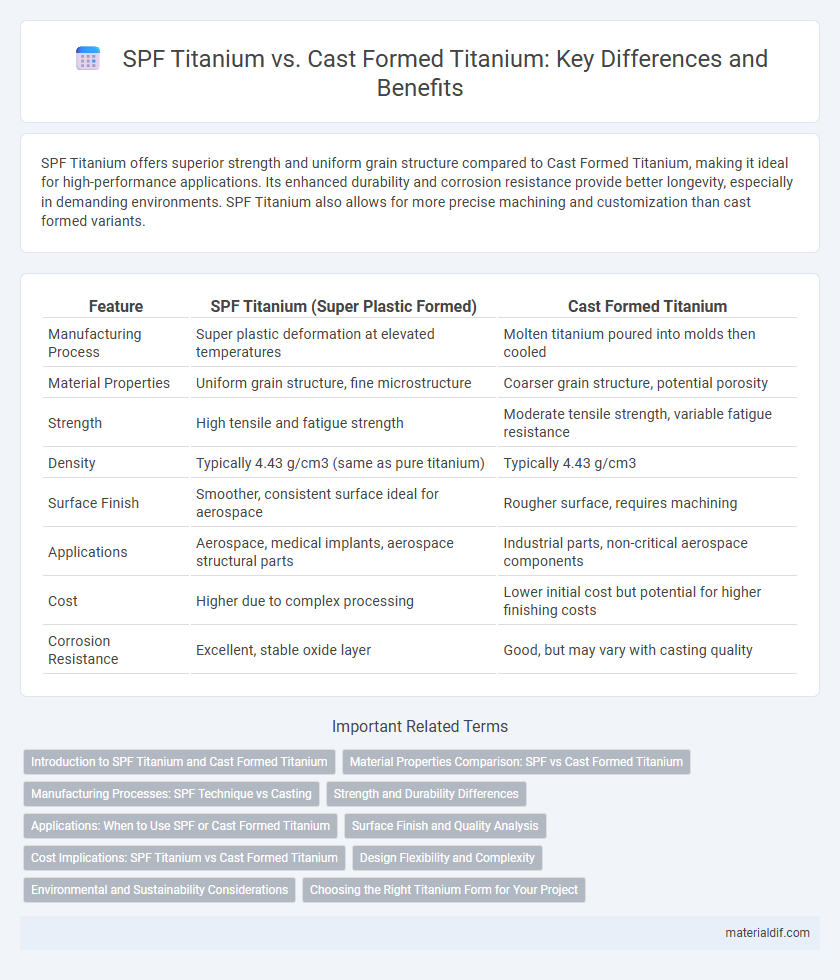

SPF Titanium offers superior strength and uniform grain structure compared to Cast Formed Titanium, making it ideal for high-performance applications. Its enhanced durability and corrosion resistance provide better longevity, especially in demanding environments. SPF Titanium also allows for more precise machining and customization than cast formed variants.

Table of Comparison

| Feature | SPF Titanium (Super Plastic Formed) | Cast Formed Titanium |

|---|---|---|

| Manufacturing Process | Super plastic deformation at elevated temperatures | Molten titanium poured into molds then cooled |

| Material Properties | Uniform grain structure, fine microstructure | Coarser grain structure, potential porosity |

| Strength | High tensile and fatigue strength | Moderate tensile strength, variable fatigue resistance |

| Density | Typically 4.43 g/cm3 (same as pure titanium) | Typically 4.43 g/cm3 |

| Surface Finish | Smoother, consistent surface ideal for aerospace | Rougher surface, requires machining |

| Applications | Aerospace, medical implants, aerospace structural parts | Industrial parts, non-critical aerospace components |

| Cost | Higher due to complex processing | Lower initial cost but potential for higher finishing costs |

| Corrosion Resistance | Excellent, stable oxide layer | Good, but may vary with casting quality |

Introduction to SPF Titanium and Cast Formed Titanium

SPF Titanium is produced through a Spraying, Forming, and Pressing technique that results in refined microstructure and enhanced mechanical properties compared to traditional methods. Cast Formed Titanium involves melting and casting the titanium alloy into molds, leading to coarser grain structures and potentially lower mechanical performance. The differences in production methods directly impact the material's strength, ductility, and corrosion resistance, which are critical for aerospace and biomedical applications.

Material Properties Comparison: SPF vs Cast Formed Titanium

SPF (Superplastic Formed) titanium exhibits enhanced ductility and uniform grain structure compared to cast formed titanium, resulting in superior strength-to-weight ratios and improved fatigue resistance. Cast formed titanium typically shows coarser grains and potential porosity that can reduce mechanical performance and increase susceptibility to stress corrosion cracking. The controlled deformation process in SPF titanium enables better dimensional accuracy and improved mechanical properties critical for aerospace and biomedical applications.

Manufacturing Processes: SPF Technique vs Casting

SPF Titanium (Superplastic Forming) utilizes high-temperature superplastic deformation allowing complex, lightweight structures with fine grain microstructures, resulting in superior mechanical properties and reduced waste. Cast Formed Titanium involves pouring molten titanium into molds, which can lead to coarser grain structures, potential porosity, and lower strength compared to SPF. The SPF technique enables precise control over material flow and thickness distribution, optimizing performance for aerospace and biomedical applications.

Strength and Durability Differences

SPF Titanium, produced through Superplastic Forming, exhibits higher tensile strength due to its refined microstructure and uniform grain distribution compared to Cast Formed Titanium. Cast Formed Titanium typically has a coarser grain structure, leading to lower fatigue resistance and reduced durability under cyclic loading conditions. This makes SPF Titanium preferable for aerospace and medical applications where enhanced strength and long-term durability are critical.

Applications: When to Use SPF or Cast Formed Titanium

SPF titanium is ideal for aerospace and automotive applications requiring complex shapes with improved mechanical properties and uniform microstructure, offering enhanced strength and fatigue resistance. Cast formed titanium suits biomedical implants and intricate turbine components where fine detail and tailored material properties are critical, especially in low-volume, custom parts. Selecting SPF or cast formed titanium depends on application-specific needs for performance, geometry, and production scale.

Surface Finish and Quality Analysis

SPF Titanium exhibits a smoother surface finish with reduced microstructural defects compared to cast formed titanium, enhancing its fatigue resistance and corrosion performance. The surface quality analysis reveals SPF Titanium's uniform grain structure reduces stress concentrators, resulting in superior mechanical properties. In contrast, cast formed titanium often shows surface irregularities and porosity, impacting its overall material integrity.

Cost Implications: SPF Titanium vs Cast Formed Titanium

SPF titanium typically incurs higher production costs due to the complex process of powder consolidation and precise control required, whereas cast formed titanium benefits from lower material waste and simplified shaping methods, reducing overall expenses. However, SPF titanium often offers superior mechanical properties, potentially justifying the initial cost for high-performance applications. In contrast, cast formed titanium is generally more cost-effective for larger, less demanding components where budget constraints are critical.

Design Flexibility and Complexity

SPF titanium offers superior design flexibility due to its ability to be tailored during the manufacturing process, enabling intricate geometries and complex shapes that cast formed titanium cannot easily achieve. Cast formed titanium, while strong, is limited by mold constraints and typically results in less detailed designs with lower accuracy. The advanced microstructure of SPF titanium also enhances its performance in complex applications requiring lightweight and structurally optimized components.

Environmental and Sustainability Considerations

SPF titanium, produced through Spray Forming Process, offers superior material efficiency by minimizing waste compared to traditional Cast Formed Titanium, which involves higher energy consumption and scrap rates. The reduced energy footprint and enhanced recyclability of SPF titanium align with sustainable manufacturing goals, lowering greenhouse gas emissions during production. Choosing SPF titanium supports eco-friendly practices by promoting resource conservation and reducing environmental impact throughout the titanium lifecycle.

Choosing the Right Titanium Form for Your Project

SPF titanium offers superior strength and enhanced fatigue resistance due to its near-net shape manufacturing, making it ideal for aerospace and high-performance engineering applications. Cast formed titanium provides excellent corrosion resistance and complex geometric flexibility, suitable for custom medical implants and intricate components. Selecting the right titanium form depends on balancing mechanical properties and design complexity to meet your project's specific performance and manufacturing requirements.

SPF Titanium vs Cast Formed Titanium Infographic

materialdif.com

materialdif.com