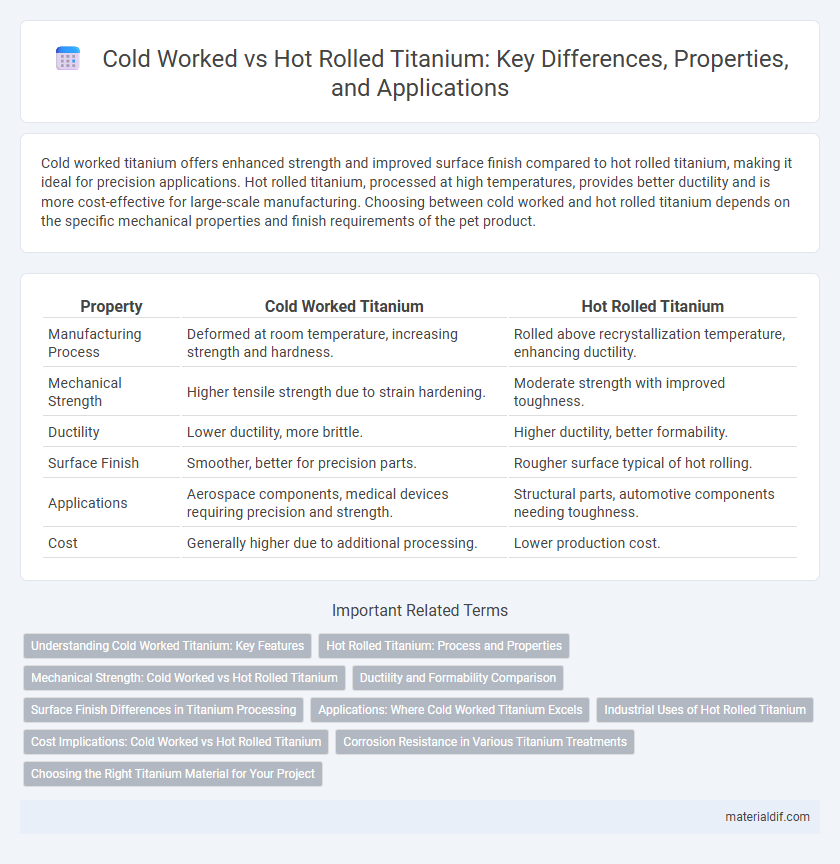

Cold worked titanium offers enhanced strength and improved surface finish compared to hot rolled titanium, making it ideal for precision applications. Hot rolled titanium, processed at high temperatures, provides better ductility and is more cost-effective for large-scale manufacturing. Choosing between cold worked and hot rolled titanium depends on the specific mechanical properties and finish requirements of the pet product.

Table of Comparison

| Property | Cold Worked Titanium | Hot Rolled Titanium |

|---|---|---|

| Manufacturing Process | Deformed at room temperature, increasing strength and hardness. | Rolled above recrystallization temperature, enhancing ductility. |

| Mechanical Strength | Higher tensile strength due to strain hardening. | Moderate strength with improved toughness. |

| Ductility | Lower ductility, more brittle. | Higher ductility, better formability. |

| Surface Finish | Smoother, better for precision parts. | Rougher surface typical of hot rolling. |

| Applications | Aerospace components, medical devices requiring precision and strength. | Structural parts, automotive components needing toughness. |

| Cost | Generally higher due to additional processing. | Lower production cost. |

Understanding Cold Worked Titanium: Key Features

Cold worked titanium undergoes plastic deformation at room temperature, enhancing its strength and hardness through strain hardening while maintaining excellent corrosion resistance. Its refined microstructure offers superior fatigue resistance and improved dimensional stability compared to hot rolled titanium, making it ideal for aerospace and medical applications. The absence of high-temperature processing preserves the titanium's grain structure, resulting in enhanced mechanical properties and a smoother surface finish.

Hot Rolled Titanium: Process and Properties

Hot rolled titanium undergoes deformation at high temperatures above 900degC, which refines its microstructure and enhances ductility while maintaining strength. This process improves grain size uniformity, resulting in better toughness and resistance to fatigue compared to cold worked titanium. Hot rolled titanium typically exhibits superior formability and dimensional stability, making it ideal for aerospace and industrial applications requiring complex shaping and high performance.

Mechanical Strength: Cold Worked vs Hot Rolled Titanium

Cold worked titanium exhibits significantly higher tensile strength and hardness compared to hot rolled titanium due to the strain hardening effects induced during deformation below its recrystallization temperature. Hot rolled titanium, processed at elevated temperatures, maintains superior ductility and toughness but with comparatively lower yield strength and tensile strength. Mechanical performance differences between cold worked and hot rolled titanium are critical in applications demanding either enhanced strength or improved formability.

Ductility and Formability Comparison

Cold worked titanium exhibits higher strength and improved surface finish but typically has reduced ductility compared to hot rolled titanium due to strain hardening during processing. Hot rolled titanium retains greater ductility and enhanced formability, making it suitable for applications requiring extensive shaping or bending. The choice between cold worked and hot rolled titanium depends on balancing the need for strength versus the ability to deform without cracking.

Surface Finish Differences in Titanium Processing

Cold worked titanium exhibits a smoother surface finish with higher hardness and enhanced strength due to strain hardening, making it ideal for applications requiring precision and corrosion resistance. Hot rolled titanium often shows a rougher, scaled surface texture resulting from high-temperature processing, which may require additional surface treatment for improved aesthetics and performance. The difference in surface finish directly impacts titanium's suitability for aerospace, medical implants, and chemical processing industries.

Applications: Where Cold Worked Titanium Excels

Cold worked titanium exhibits superior strength and enhanced surface finish, making it ideal for aerospace components, medical implants, and high-performance sports equipment where precision and durability are critical. This treatment optimizes fatigue resistance and maintains tight tolerances, benefiting applications subjected to cyclic loading and wear. Industries requiring lightweight, corrosion-resistant materials with exceptional mechanical properties frequently prefer cold worked titanium over hot rolled alternatives.

Industrial Uses of Hot Rolled Titanium

Hot rolled titanium exhibits superior ductility and structural integrity, making it ideal for industrial applications requiring high strength and corrosion resistance, such as aerospace components, chemical processing equipment, and marine hardware. Its grain structure, refined through hot rolling, enhances toughness and weldability compared to cold worked titanium, which is stronger but less formable. Industries leverage hot rolled titanium for manufacturing pressure vessels, pipelines, and heat exchangers that demand durability under extreme temperatures and harsh environments.

Cost Implications: Cold Worked vs Hot Rolled Titanium

Cold worked titanium involves mechanical deformation below recrystallization temperature, resulting in higher strength but increased manufacturing costs due to additional processing steps and tooling wear. Hot rolled titanium, processed above recrystallization temperature, offers reduced production expenses through simplified rolling and lower energy consumption, though it may exhibit lower strength and reduced dimensional accuracy. Cost implications favor hot rolled titanium for large, less strength-critical applications, while cold worked titanium is preferred in high-performance sectors despite its premium price.

Corrosion Resistance in Various Titanium Treatments

Cold worked titanium exhibits enhanced corrosion resistance due to increased dislocation density and strain hardening, which refine the passive oxide film on its surface. Hot rolled titanium, while possessing good corrosion resistance, may have a less uniform oxide layer because of grain growth and potential inclusions formed during the elevated temperature processing. The differences in microstructure between cold worked and hot rolled titanium significantly influence their performance in aggressive environments such as marine or chemical processing applications.

Choosing the Right Titanium Material for Your Project

Cold worked titanium offers higher strength and improved surface finish due to strain hardening, making it ideal for applications requiring precision and durability, such as aerospace components and medical implants. Hot rolled titanium provides superior ductility and is more cost-effective for large-scale structural projects where forming and welding are essential. Selecting the right titanium material depends on balancing mechanical properties, fabrication needs, and budget constraints relevant to your specific project requirements.

Cold Worked Titanium vs Hot Rolled Titanium Infographic

materialdif.com

materialdif.com