Titanium wire offers superior strength and flexibility, making it ideal for precise applications requiring durability and resistance to corrosion. In contrast, titanium springs provide enhanced elasticity and resilience, effectively absorbing shocks and maintaining consistent performance under repeated stress. Choosing between titanium wire and titanium springs depends on whether rigidity or flexibility is prioritized in the pet-related device or structure.

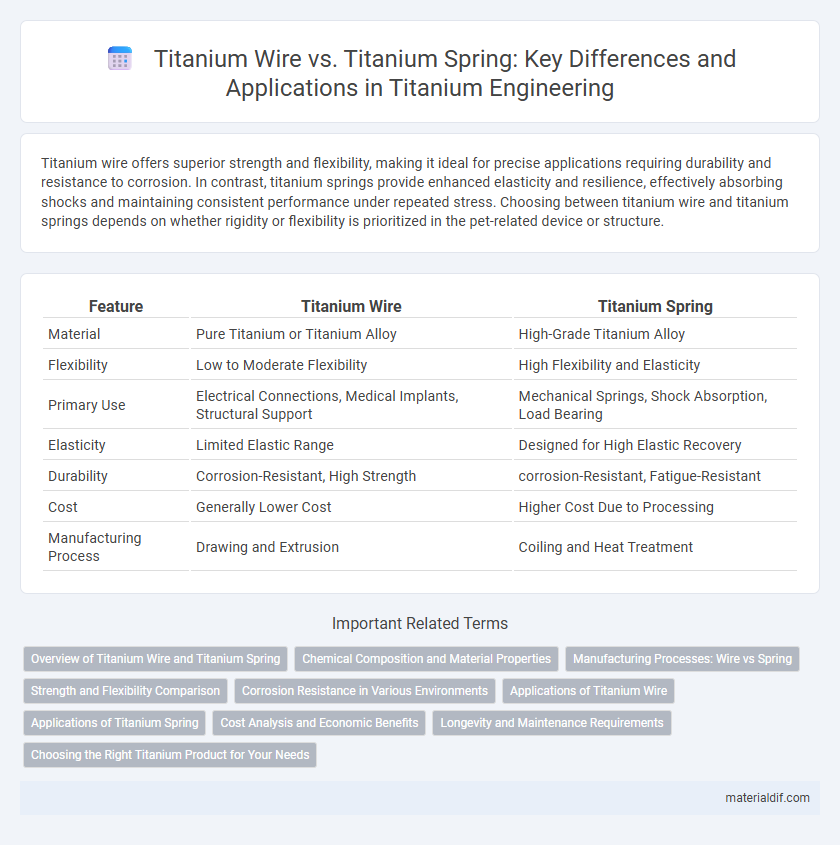

Table of Comparison

| Feature | Titanium Wire | Titanium Spring |

|---|---|---|

| Material | Pure Titanium or Titanium Alloy | High-Grade Titanium Alloy |

| Flexibility | Low to Moderate Flexibility | High Flexibility and Elasticity |

| Primary Use | Electrical Connections, Medical Implants, Structural Support | Mechanical Springs, Shock Absorption, Load Bearing |

| Elasticity | Limited Elastic Range | Designed for High Elastic Recovery |

| Durability | Corrosion-Resistant, High Strength | corrosion-Resistant, Fatigue-Resistant |

| Cost | Generally Lower Cost | Higher Cost Due to Processing |

| Manufacturing Process | Drawing and Extrusion | Coiling and Heat Treatment |

Overview of Titanium Wire and Titanium Spring

Titanium wire offers exceptional tensile strength, corrosion resistance, and lightweight properties, making it ideal for medical, aerospace, and industrial applications where precision and durability are critical. Titanium springs utilize the metal's elasticity and fatigue resistance to provide reliable performance in high-stress environments such as automotive suspensions and aerospace components. Both forms leverage titanium's biocompatibility and resistance to harsh conditions, yet titanium springs are specifically engineered for dynamic flexibility while titanium wire excels in structural and electrical functions.

Chemical Composition and Material Properties

Titanium wire primarily consists of commercially pure titanium with minimal alloying elements, offering excellent corrosion resistance and high tensile strength ideal for general use. Titanium springs are often made from titanium alloys such as Ti-6Al-4V, which include aluminum and vanadium to enhance elasticity, fatigue resistance, and mechanical strength. The difference in chemical composition between pure titanium wire and alloyed titanium springs directly influences their material properties, making springs more suitable for dynamic applications requiring resilience and durability.

Manufacturing Processes: Wire vs Spring

Titanium wire manufacturing involves precise drawing processes where titanium billets are extruded and cold-worked to achieve uniform diameter and tensile strength, ensuring high corrosion resistance and flexibility. In contrast, titanium spring production requires additional forming techniques such as coiling and heat treatment to impart elasticity and restore mechanical properties after deformation. Both processes prioritize maintaining the alloy's biocompatibility and durability, but spring manufacturing demands meticulous control of stress relief to optimize performance under cyclic loading.

Strength and Flexibility Comparison

Titanium wire exhibits exceptional tensile strength, making it ideal for applications requiring durability under heavy loads, while titanium springs prioritize flexibility and resilience to cyclic stresses without permanent deformation. The higher modulus of elasticity in titanium wire ensures superior rigidity, whereas titanium springs leverage alloy composition and coil design to optimize elastic recovery and fatigue resistance. Understanding the balance between strength and flexibility is crucial for selecting titanium materials tailored to specific engineering demands.

Corrosion Resistance in Various Environments

Titanium wire and titanium spring both exhibit exceptional corrosion resistance due to the formation of a stable oxide layer, making them ideal for use in harsh environments such as marine, chemical, and biomedical applications. Titanium spring, often subjected to continuous mechanical stress, maintains its corrosion resistance without compromising flexibility, while titanium wire offers superior durability and resistance to crack propagation in static or minimally stressed environments. Both materials outperform stainless steel and aluminum alloys in resisting oxidation, pitting, and crevice corrosion across acidic, saline, and alkaline conditions.

Applications of Titanium Wire

Titanium wire is widely used in medical devices such as surgical implants and orthodontic appliances due to its biocompatibility, corrosion resistance, and high strength-to-weight ratio. Its flexibility and durability make it ideal for aerospace components, electronic connectors, and chemical processing equipment. Unlike titanium springs, which primarily function for elasticity and load-bearing, titanium wire excels in structural and conductive roles across various industries.

Applications of Titanium Spring

Titanium springs are extensively used in aerospace, medical devices, and automotive sectors due to their exceptional corrosion resistance, high strength-to-weight ratio, and fatigue durability. Unlike titanium wire, which is primarily utilized for structural reinforcement, titanium springs provide dynamic load absorption and consistent performance under cyclic stresses. These properties make titanium springs ideal for precision instruments, prosthetics, and high-performance suspension systems where reliability and longevity are critical.

Cost Analysis and Economic Benefits

Titanium wire typically offers a lower initial cost compared to titanium springs due to simpler manufacturing processes and reduced material complexity. Although titanium springs may have a higher upfront expense, their superior elasticity and durability often lead to longer service life and lower replacement frequency, resulting in better long-term economic benefits. Cost analysis favors titanium wire for applications requiring basic tensile strength, while titanium springs provide enhanced performance that justifies higher investment through improved lifecycle cost efficiency.

Longevity and Maintenance Requirements

Titanium wire exhibits exceptional longevity due to its high tensile strength and corrosion resistance, requiring minimal maintenance with occasional inspections for wear or damage. Titanium springs, designed to endure repetitive stress, maintain their elasticity and structural integrity over extended cycles, reducing the need for frequent replacement or lubrication. Both forms benefit from titanium's inherent resistance to fatigue and environmental degradation, making them ideal for long-term applications with low upkeep demands.

Choosing the Right Titanium Product for Your Needs

Selecting the right titanium product depends on the application requirements; titanium wire offers exceptional tensile strength and flexibility ideal for medical devices and aerospace components, while titanium springs provide superior elasticity and corrosion resistance, making them suitable for mechanical and precision instruments. Titanium wire's versatility in size and diameter allows customization for intricate designs, whereas titanium springs are engineered for consistent performance under repeated stress cycles. Understanding the specific mechanical properties and environmental conditions will ensure optimal functionality and longevity of the titanium material in use.

Titanium Wire vs Titanium Spring Infographic

materialdif.com

materialdif.com