Titanium anodizing enhances the metal's surface by creating a durable oxide layer that improves corrosion resistance and allows for vibrant color customization, making it ideal for both aesthetic and protective applications. Titanium passivation, on the other hand, involves chemically treating the titanium to remove contaminants and strengthen the natural oxide layer without altering the metal's color. While anodizing emphasizes surface enhancement and visual appeal, passivation primarily focuses on increasing corrosion resistance and maintaining the metal's natural appearance.

Table of Comparison

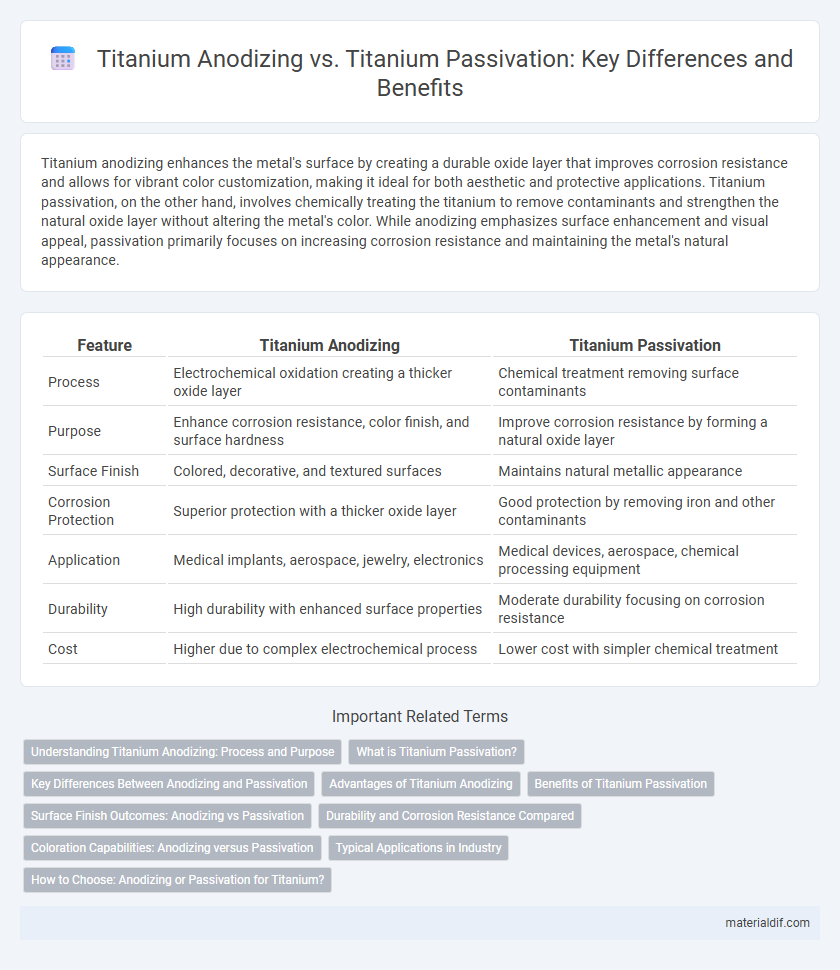

| Feature | Titanium Anodizing | Titanium Passivation |

|---|---|---|

| Process | Electrochemical oxidation creating a thicker oxide layer | Chemical treatment removing surface contaminants |

| Purpose | Enhance corrosion resistance, color finish, and surface hardness | Improve corrosion resistance by forming a natural oxide layer |

| Surface Finish | Colored, decorative, and textured surfaces | Maintains natural metallic appearance |

| Corrosion Protection | Superior protection with a thicker oxide layer | Good protection by removing iron and other contaminants |

| Application | Medical implants, aerospace, jewelry, electronics | Medical devices, aerospace, chemical processing equipment |

| Durability | High durability with enhanced surface properties | Moderate durability focusing on corrosion resistance |

| Cost | Higher due to complex electrochemical process | Lower cost with simpler chemical treatment |

Understanding Titanium Anodizing: Process and Purpose

Titanium anodizing involves electrochemically treating the metal surface to create a durable, corrosion-resistant oxide layer with enhanced aesthetic properties, such as vibrant color variations controlled by voltage adjustments. This process improves titanium's wear resistance and biocompatibility, making it essential for medical implants, aerospace components, and consumer electronics. Unlike passivation, which removes contaminants to form a thin, protective oxide film, anodizing actively modifies the surface structure to achieve specific functional and decorative outcomes.

What is Titanium Passivation?

Titanium passivation is a chemical treatment process that enhances the metal's corrosion resistance by forming a thin, protective oxide layer on its surface. This method uses acidic solutions, such as nitric acid, to remove free iron and contaminants, preventing rust and surface degradation. Unlike titanium anodizing, which alters the surface color and thickness through electrochemical means, passivation focuses solely on improving durability and extending the lifespan of titanium components.

Key Differences Between Anodizing and Passivation

Titanium anodizing enhances corrosion resistance and surface hardness by creating a thick, controlled oxide layer through electrochemical oxidation, resulting in vibrant, durable colors and improved wear resistance. Titanium passivation, in contrast, naturally forms a thin, protective oxide film by removing free iron and contaminants, primarily improving corrosion resistance without altering surface appearance or mechanical properties. The key differences lie in anodizing's ability to modify surface aesthetics and hardness, while passivation focuses solely on enhancing corrosion protection through chemical stabilization.

Advantages of Titanium Anodizing

Titanium anodizing enhances corrosion resistance by forming a thick, durable oxide layer that protects the metal surface from harsh environments and chemical exposure. This process also allows for customization of surface colors without painting, improving both aesthetic appeal and wear resistance. Compared to titanium passivation, anodizing provides superior surface hardness and long-lasting protection, making it ideal for aerospace, medical, and industrial applications.

Benefits of Titanium Passivation

Titanium passivation enhances corrosion resistance by creating a stable oxide layer that protects the metal surface from chemical reactions and environmental damage. This process improves the durability and lifespan of titanium components in harsh conditions, such as chemical processing or marine applications. Unlike anodizing, passivation maintains the metal's natural appearance while providing superior protection against rust and contamination.

Surface Finish Outcomes: Anodizing vs Passivation

Titanium anodizing enhances surface finish by creating a vibrant, corrosion-resistant oxide layer that can be precisely controlled in thickness and color, offering both aesthetic appeal and functional durability. Titanium passivation, in contrast, improves surface finish primarily by removing free iron and contaminants, forming a transparent, chemically inert oxide film that boosts corrosion resistance without altering surface coloration. The anodizing process yields a more pronounced and customizable surface finish, while passivation provides a subtle, cleaner, and protective finish essential for medical and aerospace applications.

Durability and Corrosion Resistance Compared

Titanium anodizing enhances durability by forming a thick, colorful oxide layer that significantly improves corrosion resistance in harsh environments, making it ideal for marine and industrial applications. In contrast, titanium passivation creates a thin, transparent oxide film that provides baseline corrosion protection without altering the surface appearance or mechanical properties. While anodizing offers superior resistance to wear and chemical attack due to its enhanced oxide thickness, passivation primarily prevents surface contamination and oxidation, maintaining titanium's natural longevity.

Coloration Capabilities: Anodizing versus Passivation

Titanium anodizing enhances coloration capabilities by creating an oxide layer whose thickness varies with voltage, producing vibrant, controllable colors through light interference effects. In contrast, titanium passivation primarily improves corrosion resistance without altering the surface color, maintaining the metal's natural appearance. Therefore, anodizing offers superior aesthetic versatility for applications requiring decorative or color-coded titanium finishes.

Typical Applications in Industry

Titanium anodizing is widely used in aerospace and medical industries for enhancing corrosion resistance and creating color-coded components, improving both durability and identification. Titanium passivation finds typical applications in chemical processing and marine environments, where it forms a protective oxide layer to prevent surface contamination and oxidation. Both processes are critical for extending titanium's lifespan in harsh industrial conditions, with anodizing favored for functional aesthetics and passivation for chemical inertness.

How to Choose: Anodizing or Passivation for Titanium?

Choosing between titanium anodizing and titanium passivation depends on the desired surface properties and application requirements. Anodizing enhances corrosion resistance and allows for color customization by forming a thicker oxide layer, ideal for aesthetic and protective purposes. Passivation, on the other hand, removes surface contaminants and improves natural oxide layer stability without altering color, making it suitable for medical or chemical environments where biocompatibility and purity are critical.

Titanium Anodizing vs Titanium Passivation Infographic

materialdif.com

materialdif.com