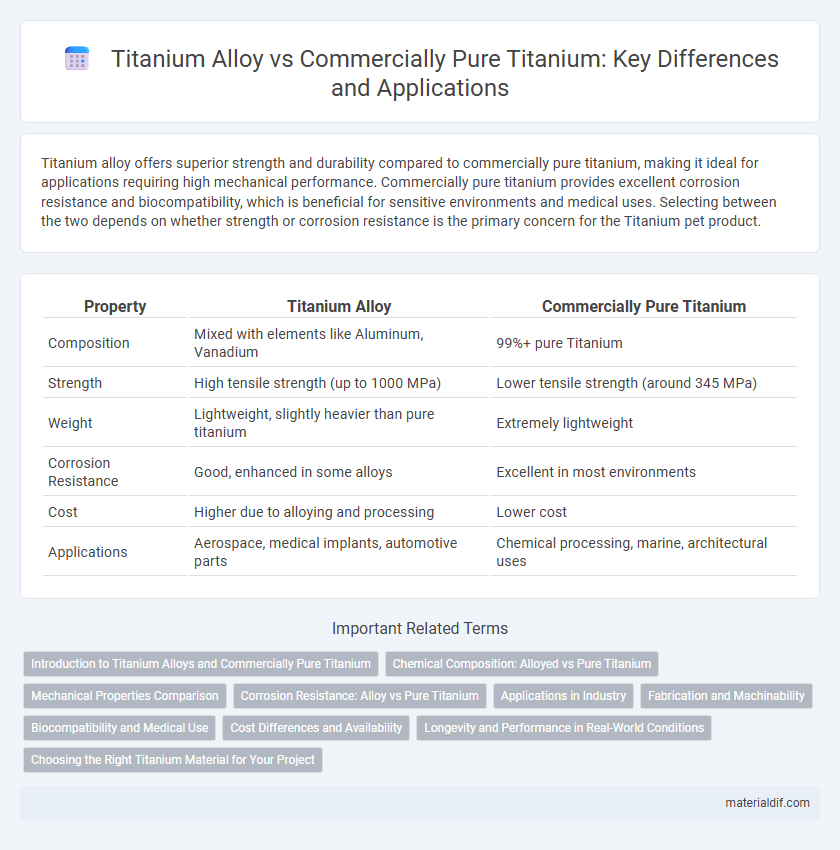

Titanium alloy offers superior strength and durability compared to commercially pure titanium, making it ideal for applications requiring high mechanical performance. Commercially pure titanium provides excellent corrosion resistance and biocompatibility, which is beneficial for sensitive environments and medical uses. Selecting between the two depends on whether strength or corrosion resistance is the primary concern for the Titanium pet product.

Table of Comparison

| Property | Titanium Alloy | Commercially Pure Titanium |

|---|---|---|

| Composition | Mixed with elements like Aluminum, Vanadium | 99%+ pure Titanium |

| Strength | High tensile strength (up to 1000 MPa) | Lower tensile strength (around 345 MPa) |

| Weight | Lightweight, slightly heavier than pure titanium | Extremely lightweight |

| Corrosion Resistance | Good, enhanced in some alloys | Excellent in most environments |

| Cost | Higher due to alloying and processing | Lower cost |

| Applications | Aerospace, medical implants, automotive parts | Chemical processing, marine, architectural uses |

Introduction to Titanium Alloys and Commercially Pure Titanium

Titanium alloys, primarily composed of titanium mixed with elements such as aluminum, vanadium, or molybdenum, offer enhanced strength, corrosion resistance, and elevated temperature performance compared to commercially pure titanium (CP-Ti). Commercially pure titanium, classified into grades 1 through 4 based on oxygen content, provides excellent corrosion resistance and ductility but lower mechanical strength than titanium alloys. Applications demanding high strength-to-weight ratios and fatigue resistance typically utilize titanium alloys, whereas CP-Ti is favored in environments requiring maximum corrosion resistance and formability.

Chemical Composition: Alloyed vs Pure Titanium

Titanium alloys contain controlled amounts of elements such as aluminum, vanadium, and molybdenum, enhancing mechanical properties like strength and corrosion resistance compared to commercially pure titanium. Commercially pure titanium consists primarily of elemental titanium with minimal impurities, typically classified into grades 1 through 4 based on oxygen and iron content. The alloying elements in titanium alloys modify phase structures, resulting in distinct variations in chemical composition and performance characteristics between the two.

Mechanical Properties Comparison

Titanium alloys exhibit significantly higher tensile strength and fatigue resistance compared to commercially pure titanium, making them ideal for high-stress applications in aerospace and automotive industries. Commercially pure titanium offers superior corrosion resistance and ductility but has lower yield strength and hardness, limiting its use in structural components. The choice between titanium alloy and commercially pure titanium depends on balancing mechanical performance requirements with environmental durability and fabrication needs.

Corrosion Resistance: Alloy vs Pure Titanium

Titanium alloys typically contain elements such as aluminum and vanadium, which can reduce corrosion resistance compared to commercially pure titanium due to galvanic interactions within the alloy matrix. In contrast, commercially pure titanium exhibits superior corrosion resistance, especially in oxidizing and reducing environments, owing to its stable and continuous titanium oxide passive layer. This makes commercially pure titanium ideal for highly corrosive applications like marine and chemical processing industries.

Applications in Industry

Titanium alloys are widely used in aerospace, automotive, and medical industries due to their superior strength-to-weight ratio and enhanced corrosion resistance compared to commercially pure titanium. Commercially pure titanium finds application in chemical processing, marine, and biomedical implants where excellent corrosion resistance and biocompatibility are critical. The distinct mechanical properties of titanium alloys make them ideal for structural components, while commercially pure titanium suits environments requiring high corrosion resistance but lower mechanical strength.

Fabrication and Machinability

Titanium alloys exhibit superior strength and hardness compared to commercially pure titanium, making their fabrication more challenging and often requiring specialized techniques such as precision machining and controlled heat treatments. Commercially pure titanium offers excellent workability and is easier to machine due to its lower strength and higher ductility, which reduces tool wear and machining time. Advanced manufacturing processes like additive manufacturing and CNC machining are increasingly employed to optimize the fabrication of titanium alloys for aerospace and medical applications.

Biocompatibility and Medical Use

Titanium alloys, such as Ti-6Al-4V, exhibit enhanced mechanical strength compared to commercially pure titanium (CP Ti), making them favorable for load-bearing medical implants while maintaining excellent biocompatibility. CP Ti demonstrates superior corrosion resistance and minimal ion release, reducing the risk of inflammatory responses in patients, which is critical for long-term implant success. Both materials are widely used in orthopedic and dental implants, with titanium alloys preferred for their durability and CP Ti favored for applications requiring maximum biological inertness.

Cost Differences and Availability

Titanium alloy generally costs more than commercially pure titanium due to the addition of alloying elements like aluminum and vanadium that enhance strength and corrosion resistance. Commercially pure titanium is widely available and more economical for applications demanding excellent corrosion resistance but lower mechanical strength. Titanium alloys, while pricier, offer superior performance in aerospace and medical industries where strength-to-weight ratio is critical, justifying their limited yet strategic availability.

Longevity and Performance in Real-World Conditions

Titanium alloy offers superior strength-to-weight ratio and enhanced corrosion resistance compared to commercially pure titanium, making it more durable under extreme stress and harsh environmental conditions. In real-world applications such as aerospace and medical implants, titanium alloys maintain structural integrity and performance longevity, reducing the risk of deformation and fatigue failure. Commercially pure titanium, while highly corrosion-resistant and biocompatible, typically demonstrates lower mechanical strength and may not perform as well in high-load scenarios over extended periods.

Choosing the Right Titanium Material for Your Project

Titanium alloy offers superior strength and corrosion resistance compared to commercially pure titanium, making it ideal for high-stress applications such as aerospace and medical implants. Commercially pure titanium excels in biocompatibility and formability, suitable for projects requiring excellent corrosion resistance and lightweight properties without the need for extreme strength. Evaluating project requirements like mechanical load, environmental exposure, and fabrication processes ensures the optimal choice between titanium alloy and commercially pure titanium.

Titanium Alloy vs Commercially Pure Titanium Infographic

materialdif.com

materialdif.com