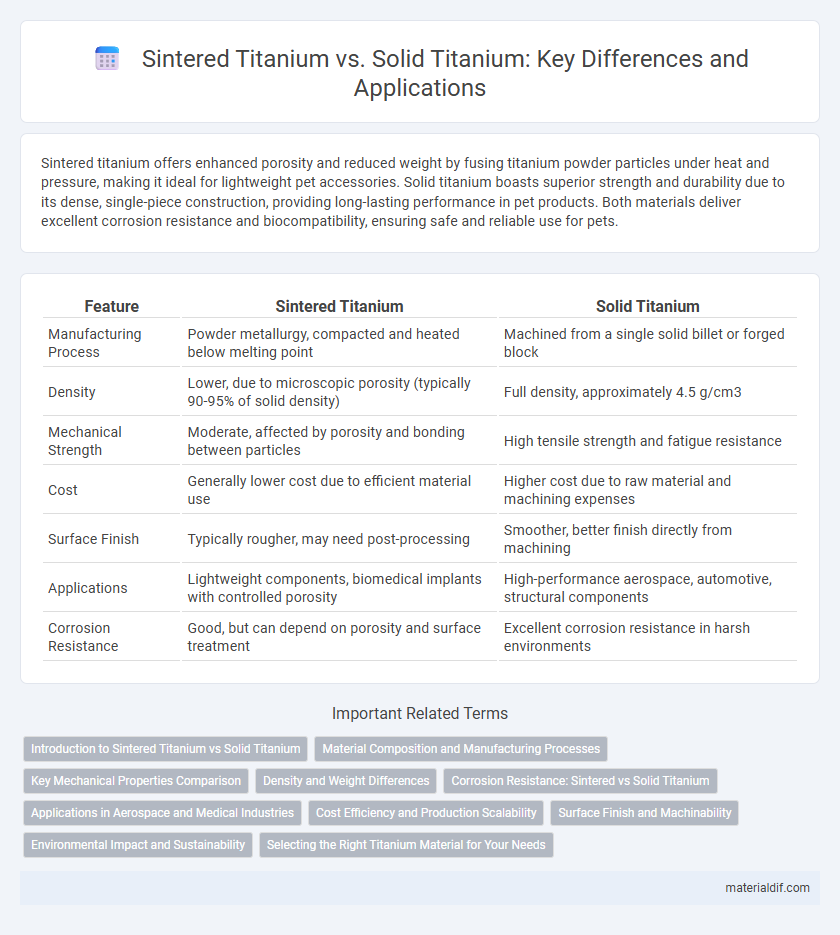

Sintered titanium offers enhanced porosity and reduced weight by fusing titanium powder particles under heat and pressure, making it ideal for lightweight pet accessories. Solid titanium boasts superior strength and durability due to its dense, single-piece construction, providing long-lasting performance in pet products. Both materials deliver excellent corrosion resistance and biocompatibility, ensuring safe and reliable use for pets.

Table of Comparison

| Feature | Sintered Titanium | Solid Titanium |

|---|---|---|

| Manufacturing Process | Powder metallurgy, compacted and heated below melting point | Machined from a single solid billet or forged block |

| Density | Lower, due to microscopic porosity (typically 90-95% of solid density) | Full density, approximately 4.5 g/cm3 |

| Mechanical Strength | Moderate, affected by porosity and bonding between particles | High tensile strength and fatigue resistance |

| Cost | Generally lower cost due to efficient material use | Higher cost due to raw material and machining expenses |

| Surface Finish | Typically rougher, may need post-processing | Smoother, better finish directly from machining |

| Applications | Lightweight components, biomedical implants with controlled porosity | High-performance aerospace, automotive, structural components |

| Corrosion Resistance | Good, but can depend on porosity and surface treatment | Excellent corrosion resistance in harsh environments |

Introduction to Sintered Titanium vs Solid Titanium

Sintered titanium is produced through a powder metallurgy process where titanium powder is compacted and heated below its melting point, enhancing material density and mechanical properties. Solid titanium, in contrast, is derived from wrought or cast titanium, offering uniform microstructure and superior strength. Understanding the differences in microstructure, density, and mechanical performance between sintered and solid titanium is essential for selecting materials in aerospace, biomedical, and industrial applications.

Material Composition and Manufacturing Processes

Sintered titanium is produced by compacting and heating titanium powder below its melting point, resulting in a porous structure with controlled density and mechanical properties, while solid titanium is formed through traditional casting or forging of bulk titanium ingots, yielding a fully dense material. The material composition of sintered titanium may include trace additives to enhance sintering efficiency and mechanical strength, whereas solid titanium typically maintains a pure or alloyed composition with consistent elemental distribution. Manufacturing processes for sintered titanium emphasize powder metallurgy techniques optimizing particle bonding, contrasting with the high-temperature thermomechanical treatments applied to solid titanium to refine grain structure and mechanical performance.

Key Mechanical Properties Comparison

Sintered titanium exhibits lower tensile strength and fatigue resistance compared to solid titanium due to its porous microstructure, which can impact load-bearing applications. Solid titanium offers superior mechanical properties, including higher yield strength, improved ductility, and greater hardness, making it ideal for aerospace and biomedical implants. The density and uniform grain structure of solid titanium contribute to its enhanced toughness and corrosion resistance relative to sintered counterparts.

Density and Weight Differences

Sintered titanium exhibits a lower density compared to solid titanium due to its porous structure formed through powder metallurgy, resulting in significant weight reduction. Solid titanium, being a fully consolidated material, has a density of approximately 4.5 g/cm3, providing higher mechanical strength but increased weight. The reduced density in sintered titanium components makes them advantageous for aerospace and biomedical applications where weight savings are critical without drastically compromising strength.

Corrosion Resistance: Sintered vs Solid Titanium

Sintered titanium exhibits superior corrosion resistance compared to solid titanium due to its uniform microstructure and reduced impurities achieved during the powder metallurgy process. This enhanced corrosion resistance makes sintered titanium ideal for applications in aggressive chemical environments and biomedical implants. In contrast, solid titanium may have more heterogeneous grain structures, potentially leading to localized corrosion under certain conditions.

Applications in Aerospace and Medical Industries

Sintered titanium offers enhanced porosity and precise control over microstructure, making it ideal for aerospace components requiring lightweight strength and complex geometries, such as turbine blades and structural parts. In the medical industry, sintered titanium's porous nature promotes osseointegration in implants like dental and orthopedic devices, improving patient outcomes. Solid titanium, known for its high strength, corrosion resistance, and fatigue durability, is preferred for critical aerospace components like airframes and engine parts, as well as load-bearing medical implants demanding long-term stability.

Cost Efficiency and Production Scalability

Sintered titanium offers significant cost efficiency by reducing raw material waste and lowering energy consumption compared to solid titanium manufacturing. Its production scalability is enhanced through additive manufacturing techniques, allowing complex geometries to be produced rapidly without the need for extensive machining. In contrast, solid titanium requires extensive machining and material removal, increasing production costs and limiting scalability for large or intricate components.

Surface Finish and Machinability

Sintered titanium typically presents a rougher surface finish due to its porous microstructure, which can negatively impact aesthetics and corrosion resistance, while solid titanium offers a smoother, more uniform surface ideal for high-precision applications. Machinability of sintered titanium is generally lower because its porosity causes tool wear and inconsistent cutting forces, contrasting with the superior machinability of solid titanium that allows for precise shaping and finishing. The choice between sintered and solid titanium depends heavily on the required surface quality and machining efficiency in aerospace, medical, or automotive industries.

Environmental Impact and Sustainability

Sintered titanium production reduces material waste and energy consumption compared to solid titanium manufacturing, resulting in a lower carbon footprint. The additive nature of sintering minimizes scrap and allows for recycling of unused powders, enhancing resource efficiency. Solid titanium typically involves extensive machining and forging processes, which generate higher emissions and resource depletion, making sintered titanium a more sustainable option in advanced manufacturing.

Selecting the Right Titanium Material for Your Needs

Sintered titanium offers enhanced porosity and improved biocompatibility, making it ideal for medical implants and applications requiring bone integration. Solid titanium provides superior strength and corrosion resistance, suitable for aerospace, automotive, and structural components demanding high durability. Selecting the right titanium material depends on the balance needed between mechanical performance and biological compatibility for your specific application.

Sintered Titanium vs Solid Titanium Infographic

materialdif.com

materialdif.com