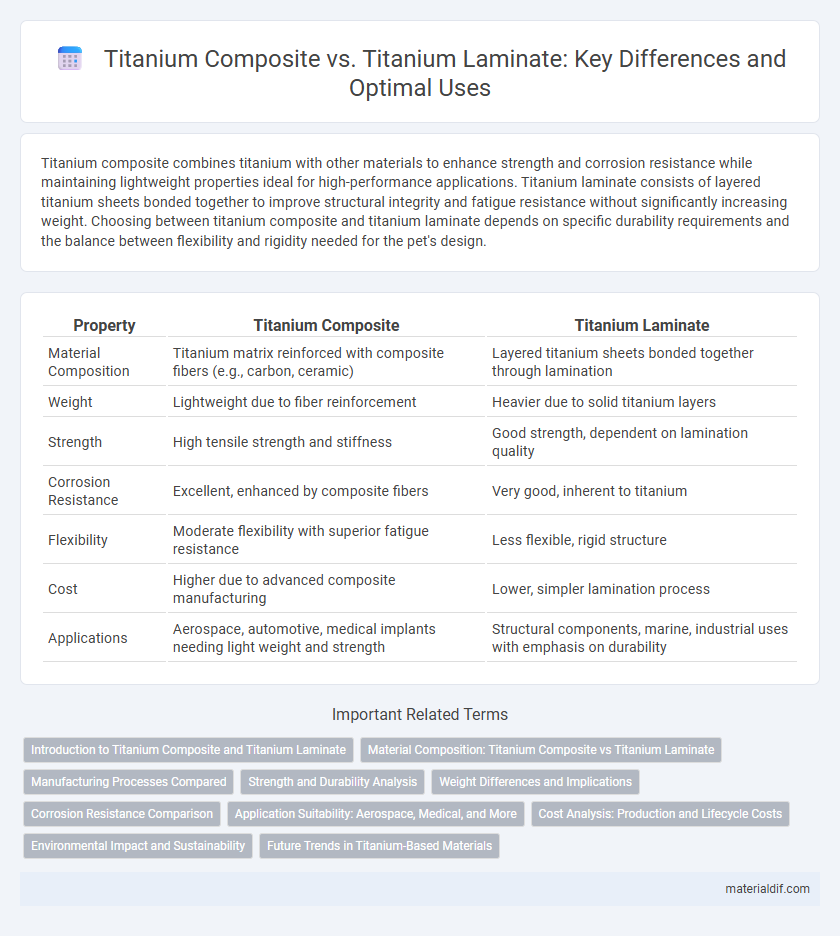

Titanium composite combines titanium with other materials to enhance strength and corrosion resistance while maintaining lightweight properties ideal for high-performance applications. Titanium laminate consists of layered titanium sheets bonded together to improve structural integrity and fatigue resistance without significantly increasing weight. Choosing between titanium composite and titanium laminate depends on specific durability requirements and the balance between flexibility and rigidity needed for the pet's design.

Table of Comparison

| Property | Titanium Composite | Titanium Laminate |

|---|---|---|

| Material Composition | Titanium matrix reinforced with composite fibers (e.g., carbon, ceramic) | Layered titanium sheets bonded together through lamination |

| Weight | Lightweight due to fiber reinforcement | Heavier due to solid titanium layers |

| Strength | High tensile strength and stiffness | Good strength, dependent on lamination quality |

| Corrosion Resistance | Excellent, enhanced by composite fibers | Very good, inherent to titanium |

| Flexibility | Moderate flexibility with superior fatigue resistance | Less flexible, rigid structure |

| Cost | Higher due to advanced composite manufacturing | Lower, simpler lamination process |

| Applications | Aerospace, automotive, medical implants needing light weight and strength | Structural components, marine, industrial uses with emphasis on durability |

Introduction to Titanium Composite and Titanium Laminate

Titanium composites combine titanium with other materials like carbon fiber to enhance strength, reduce weight, and improve corrosion resistance, making them ideal for aerospace and automotive applications. Titanium laminates are layered materials where thin titanium sheets are bonded with other metals or composites, offering superior stiffness and damage tolerance. Both materials leverage titanium's excellent mechanical properties but serve distinct purposes depending on performance requirements.

Material Composition: Titanium Composite vs Titanium Laminate

Titanium composite materials consist of titanium metal matrix reinforced with fibers such as carbon or ceramic, enhancing strength and reducing weight. Titanium laminates are fabricated by stacking multiple thin titanium alloy layers, often incorporating different titanium grades or interlayers to optimize mechanical properties and corrosion resistance. The key distinction lies in the composite's heterogeneous fiber reinforcement versus the laminate's homogeneous layered metal structure.

Manufacturing Processes Compared

Titanium composites are typically manufactured using advanced techniques such as powder metallurgy or diffusion bonding, which involve layering titanium powders or foils with reinforcing materials under high pressure and temperature. Titanium laminates are produced through processes like hot pressing or autoclaving, where multiple titanium sheets are stacked and bonded together to form a solid, layered structure. Compared to laminates, composites offer greater design flexibility and strength-to-weight ratio due to the integration of reinforcing fibers within the titanium matrix.

Strength and Durability Analysis

Titanium composites exhibit superior strength-to-weight ratios due to their enhanced fiber reinforcement, offering increased tensile strength and impact resistance compared to titanium laminates. Titanium laminates, while still strong, tend to have reduced fatigue resistance and are more susceptible to delamination under cyclic loading conditions. The durability of titanium composites surpasses that of laminates in harsh environments, making composites preferable for high-performance aerospace and automotive applications.

Weight Differences and Implications

Titanium composites typically offer a significant weight reduction compared to titanium laminates due to their integration of lightweight matrix materials with titanium fibers, enhancing strength-to-weight ratios. Laminates, consisting of stacked titanium layers, generally have higher density and weight, which can impact fuel efficiency and performance in aerospace and automotive applications. Choosing titanium composites over laminates results in improved structural efficiency and lower overall weight, critical for industries prioritizing weight savings without compromising strength and durability.

Corrosion Resistance Comparison

Titanium composites exhibit superior corrosion resistance due to their engineered matrix structure, which enhances protection against oxidative and chloride environments compared to titanium laminates. The layered configuration of titanium laminates may create galvanic cells at interfaces, increasing susceptibility to localized corrosion such as pitting and crevice corrosion. Advanced titanium composite materials maintain integrity in aggressive marine and chemical atmospheres, making them preferable for high-performance applications requiring long-term durability.

Application Suitability: Aerospace, Medical, and More

Titanium composite materials offer superior strength-to-weight ratios and fatigue resistance, making them ideal for aerospace applications such as aircraft structural components and engine parts. Titanium laminates provide enhanced corrosion resistance and biocompatibility, which are critical for medical implants and surgical instruments. Both materials are increasingly utilized in automotive and sports industries where strength, durability, and weight savings are key factors.

Cost Analysis: Production and Lifecycle Costs

Titanium composites generally exhibit lower production costs than titanium laminates due to their simpler fabrication processes and reduced material waste. Lifecycle costs for titanium composites are often more favorable, driven by their enhanced corrosion resistance and fatigue performance, which minimize maintenance and replacement expenses. Conversely, titanium laminates can incur higher upfront costs but may offer superior load-bearing capabilities in specific aerospace and industrial applications, impacting the total cost of ownership.

Environmental Impact and Sustainability

Titanium composite materials generally offer a lower environmental impact compared to titanium laminates due to their reduced weight and enhanced durability, leading to less frequent replacements and lower energy consumption during transportation. These composites often incorporate recycled titanium powder or green manufacturing processes, further enhancing sustainability credentials. In contrast, titanium laminates typically involve more energy-intensive production methods and can generate higher waste levels, making composites a more eco-friendly choice in aerospace and automotive applications.

Future Trends in Titanium-Based Materials

Titanium composites exhibit superior strength-to-weight ratios and enhanced fatigue resistance compared to titanium laminates, driving their increased adoption in aerospace and automotive industries. Advances in nanotechnology and additive manufacturing are accelerating the development of multi-functional titanium-based materials with tailored properties. Future trends emphasize eco-friendly production processes, improved corrosion resistance, and integration of smart sensing capabilities within titanium composites.

Titanium Composite vs Titanium Laminate Infographic

materialdif.com

materialdif.com