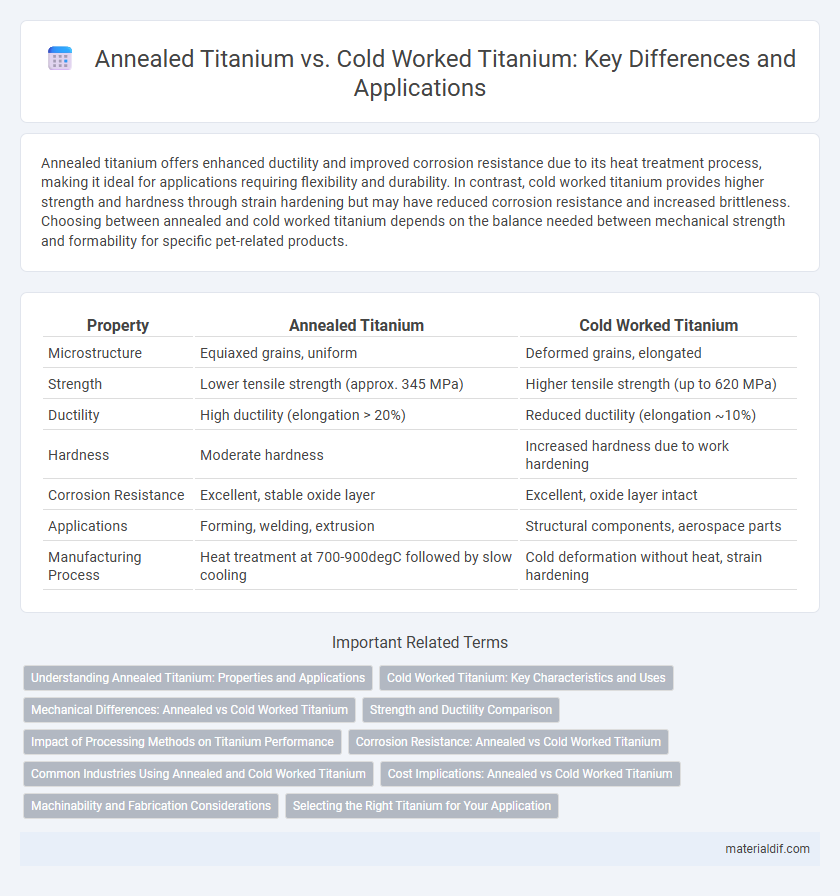

Annealed titanium offers enhanced ductility and improved corrosion resistance due to its heat treatment process, making it ideal for applications requiring flexibility and durability. In contrast, cold worked titanium provides higher strength and hardness through strain hardening but may have reduced corrosion resistance and increased brittleness. Choosing between annealed and cold worked titanium depends on the balance needed between mechanical strength and formability for specific pet-related products.

Table of Comparison

| Property | Annealed Titanium | Cold Worked Titanium |

|---|---|---|

| Microstructure | Equiaxed grains, uniform | Deformed grains, elongated |

| Strength | Lower tensile strength (approx. 345 MPa) | Higher tensile strength (up to 620 MPa) |

| Ductility | High ductility (elongation > 20%) | Reduced ductility (elongation ~10%) |

| Hardness | Moderate hardness | Increased hardness due to work hardening |

| Corrosion Resistance | Excellent, stable oxide layer | Excellent, oxide layer intact |

| Applications | Forming, welding, extrusion | Structural components, aerospace parts |

| Manufacturing Process | Heat treatment at 700-900degC followed by slow cooling | Cold deformation without heat, strain hardening |

Understanding Annealed Titanium: Properties and Applications

Annealed titanium exhibits enhanced ductility and improved corrosion resistance due to its heat treatment process, which relieves internal stresses and refines its microstructure. This form of titanium is commonly used in aerospace components, medical implants, and chemical processing equipment where flexibility and durability are critical. The annealing process allows titanium to maintain strength while improving machinability and formability compared to cold worked titanium, making it ideal for complex shaping and welding applications.

Cold Worked Titanium: Key Characteristics and Uses

Cold worked titanium exhibits enhanced strength and hardness due to plastic deformation at room temperature, resulting in improved mechanical properties compared to annealed titanium. It retains excellent corrosion resistance and lightweight characteristics, making it ideal for aerospace components, medical devices, and high-performance sports equipment. The cold working process increases tensile strength and fatigue resistance, enabling titanium to perform effectively under demanding structural applications.

Mechanical Differences: Annealed vs Cold Worked Titanium

Annealed titanium exhibits improved ductility and reduced hardness due to its stress-relieved microstructure, making it ideal for applications requiring extensive forming or machining. Cold worked titanium, conversely, has enhanced tensile strength and yield strength achieved through strain hardening, resulting in increased hardness but reduced elongation. These mechanical differences dictate the material's suitability depending on whether flexibility or strength is prioritized in aerospace, medical, or industrial applications.

Strength and Ductility Comparison

Annealed titanium exhibits lower strength but significantly higher ductility, making it ideal for applications requiring extensive forming and shaping. Cold worked titanium undergoes strain hardening, resulting in increased tensile strength and hardness while sacrificing some ductility. The balance between strength and ductility in titanium alloys depends on the degree of cold working or annealing applied during processing.

Impact of Processing Methods on Titanium Performance

Annealed titanium exhibits enhanced ductility and improved corrosion resistance due to its recrystallized grain structure formed during the annealing process. Cold worked titanium, processed through deformation methods like rolling or drawing, shows increased strength and hardness but reduced ductility because of strain hardening and dislocation buildup. The choice between annealed and cold worked titanium directly impacts performance characteristics critical for aerospace, medical implants, and chemical processing applications where specific mechanical properties and durability are required.

Corrosion Resistance: Annealed vs Cold Worked Titanium

Annealed titanium exhibits superior corrosion resistance due to its relaxed atomic structure and reduced internal stresses, making it highly effective in aggressive environments such as seawater and chemical processing. Cold worked titanium, while possessing increased strength from strain hardening, tends to have localized internal stresses that can act as initiation sites for corrosion, particularly in chloride-rich conditions. Selecting annealed titanium ensures enhanced durability and longevity in applications demanding maximum corrosion resistance.

Common Industries Using Annealed and Cold Worked Titanium

Annealed titanium is widely used in aerospace, medical implants, and automotive industries due to its improved ductility and corrosion resistance. Cold worked titanium finds applications in marine, chemical processing, and industrial manufacturing sectors where higher strength and fatigue resistance are critical. Both forms cater to specialized demands in aerospace and biomedical fields, leveraging their unique mechanical properties.

Cost Implications: Annealed vs Cold Worked Titanium

Annealed titanium typically incurs higher initial manufacturing costs due to the energy-intensive heat treatment process designed to enhance ductility and reduce residual stresses. Cold worked titanium often entails lower upfront expenses but may increase long-term costs because of reduced corrosion resistance and potential fatigue issues requiring more frequent maintenance or replacement. Evaluating total lifecycle costs reveals annealed titanium as a cost-effective option for applications demanding durability and reliability.

Machinability and Fabrication Considerations

Annealed titanium offers improved machinability due to its softer microstructure, making it easier to cut and shape compared to cold worked titanium, which is harder and more resistant to deformation. Cold worked titanium exhibits higher strength and better fatigue resistance but presents challenges such as increased tool wear and slower machining speeds during fabrication. Selecting between annealed and cold worked titanium depends on balancing machinability with desired mechanical properties for specific manufacturing processes.

Selecting the Right Titanium for Your Application

Annealed titanium offers enhanced ductility and corrosion resistance, making it ideal for applications requiring complex forming and prolonged exposure to harsh environments. Cold worked titanium provides increased strength and hardness through strain hardening, suitable for structural components subjected to high stress. Choosing the right titanium depends on balancing mechanical properties with environmental demands to optimize performance and longevity.

Annealed Titanium vs Cold Worked Titanium Infographic

materialdif.com

materialdif.com