Titanium bars offer superior strength and durability, making them ideal for heavy-duty applications that require high tensile strength and resistance to corrosion. Titanium sheets provide greater flexibility and are better suited for lightweight projects needing easy shaping and welding capabilities. Choosing between titanium bar and titanium sheet depends on the specific structural and design requirements of the pet product.

Table of Comparison

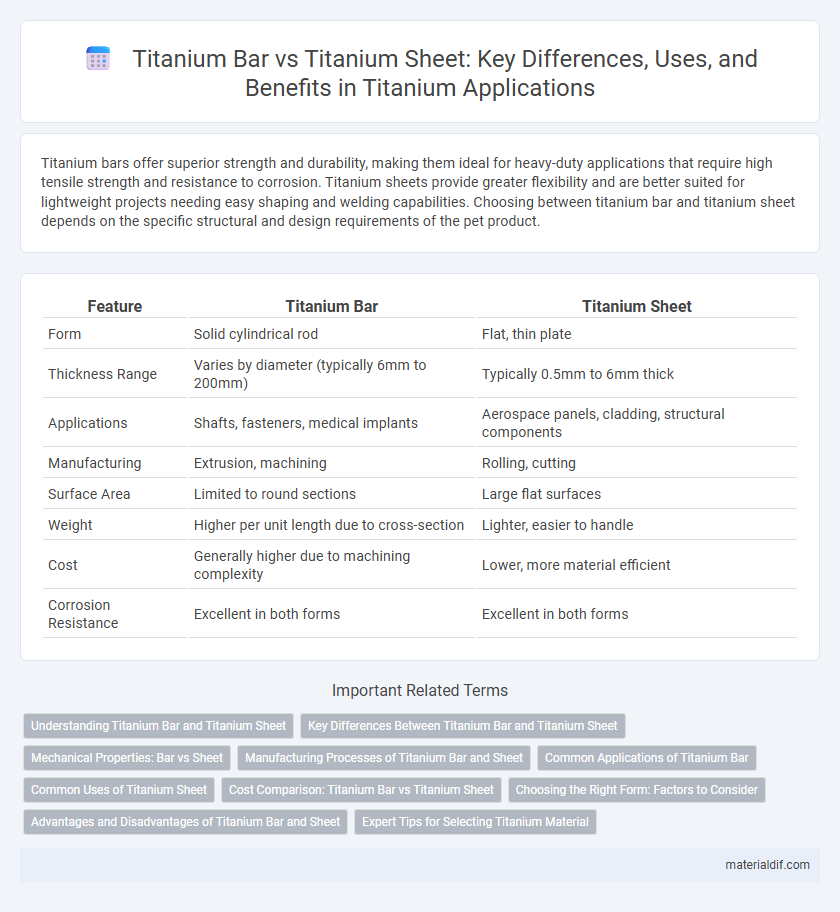

| Feature | Titanium Bar | Titanium Sheet |

|---|---|---|

| Form | Solid cylindrical rod | Flat, thin plate |

| Thickness Range | Varies by diameter (typically 6mm to 200mm) | Typically 0.5mm to 6mm thick |

| Applications | Shafts, fasteners, medical implants | Aerospace panels, cladding, structural components |

| Manufacturing | Extrusion, machining | Rolling, cutting |

| Surface Area | Limited to round sections | Large flat surfaces |

| Weight | Higher per unit length due to cross-section | Lighter, easier to handle |

| Cost | Generally higher due to machining complexity | Lower, more material efficient |

| Corrosion Resistance | Excellent in both forms | Excellent in both forms |

Understanding Titanium Bar and Titanium Sheet

Titanium bars are solid, cylindrical metal pieces commonly used for machining and manufacturing components requiring high strength and corrosion resistance. Titanium sheets are thin, flat metal plates ideal for applications needing lightweight, durable materials with excellent formability and weldability. Selecting between titanium bar and sheet depends on specific project requirements such as shape, structural integrity, and fabrication methods.

Key Differences Between Titanium Bar and Titanium Sheet

Titanium bars offer superior strength and are ideal for applications requiring high load-bearing capacity, while titanium sheets provide excellent surface area coverage and are preferred for lightweight, flat structures. Bars are typically used in aerospace and industrial machinery due to their durability and resistance to deformation, whereas sheets are favored in automotive and architectural cladding for their corrosion resistance and flexibility. The primary differences lie in their shape, mechanical properties, and typical application domains, influencing material choice based on specific engineering requirements.

Mechanical Properties: Bar vs Sheet

Titanium bars typically exhibit higher tensile strength and greater fatigue resistance compared to titanium sheets, making them ideal for applications requiring robust mechanical performance and durability. Titanium sheets, however, offer superior flexibility and formability, suitable for complex shapes and lightweight structural components. Both forms maintain excellent corrosion resistance and strength-to-weight ratios, but the choice depends on specific mechanical property requirements and intended use.

Manufacturing Processes of Titanium Bar and Sheet

Titanium bars are typically manufactured through processes such as extrusion, forging, and rolling, which enhance their strength and structural integrity for use in aerospace and medical industries. Titanium sheets are produced by hot rolling or cold rolling titanium slabs, followed by annealing to achieve desired thickness and surface finish for applications in marine and automotive sectors. Both methods require precise control of temperature and processing conditions to maintain the metal's corrosion resistance and mechanical properties.

Common Applications of Titanium Bar

Titanium bars are widely used in aerospace components, medical implants, and marine equipment due to their exceptional strength, corrosion resistance, and machinability. Unlike titanium sheets, which are preferred for lightweight structural panels and cladding, titanium bars are ideal for manufacturing shafting, fasteners, and heavy-duty mechanical parts requiring high tensile strength. Common applications of titanium bars also include automotive parts, industrial machinery, and sports equipment where durability and toughness are critical.

Common Uses of Titanium Sheet

Titanium sheets are extensively used in aerospace for aircraft skins and structural components due to their high strength-to-weight ratio and corrosion resistance. They are also common in medical implants and surgical instruments, where biocompatibility is crucial. In contrast, titanium bars are typically utilized for machining into precision parts and fasteners requiring solid stock material.

Cost Comparison: Titanium Bar vs Titanium Sheet

Titanium bars typically cost more per pound than titanium sheets due to their higher manufacturing complexity and lower material yield. Titanium sheets offer a more cost-effective solution for large surface applications because their production process allows for thinner, uniform material at scale. When budgeting for titanium, considering the intended use and required dimensions helps determine whether the higher price of bars or the efficiency of sheets provides better value.

Choosing the Right Form: Factors to Consider

Selecting between titanium bar and titanium sheet depends on the application's mechanical requirements, with bars offering superior tensile strength and durability for structural components, while sheets provide flexibility and ease of fabrication for surface applications. Consider factors such as thickness, load-bearing capacity, and corrosion resistance relevant to the operating environment to ensure optimal material performance. Cost-effectiveness and machining capabilities also influence the decision, as bars typically require more extensive processing compared to sheets.

Advantages and Disadvantages of Titanium Bar and Sheet

Titanium bars offer superior strength and durability, making them ideal for structural and load-bearing applications, but they are typically heavier and less versatile in shaping compared to titanium sheets. Titanium sheets provide excellent flexibility and a lightweight profile, suitable for aerospace and automotive uses that require precise forming, though they may lack the same mechanical strength as bars. Both forms exhibit excellent corrosion resistance and biocompatibility, but choosing between them depends on the balance of strength, weight, and fabrication requirements for specific projects.

Expert Tips for Selecting Titanium Material

Experts recommend choosing titanium bars for applications requiring exceptional strength and durability, such as aerospace components and medical implants, due to their solid, uniform structure. Titanium sheets offer superior flexibility and ease of fabrication, making them ideal for automotive panels, architectural elements, and custom metalwork. Assessing specific project demands, load requirements, and corrosion resistance ensures optimal titanium material selection tailored to performance and longevity.

Titanium Bar vs Titanium Sheet Infographic

materialdif.com

materialdif.com