Titanium coating offers a lightweight, cost-effective layer of protection for pets' accessories, increasing durability while maintaining aesthetic appeal. Solid titanium, however, provides superior strength, corrosion resistance, and hypoallergenic properties, making it ideal for long-term use in pet tags and collars. Choosing between titanium coating and solid titanium depends on budget and durability needs, with solid titanium delivering premium longevity and safety for pets.

Table of Comparison

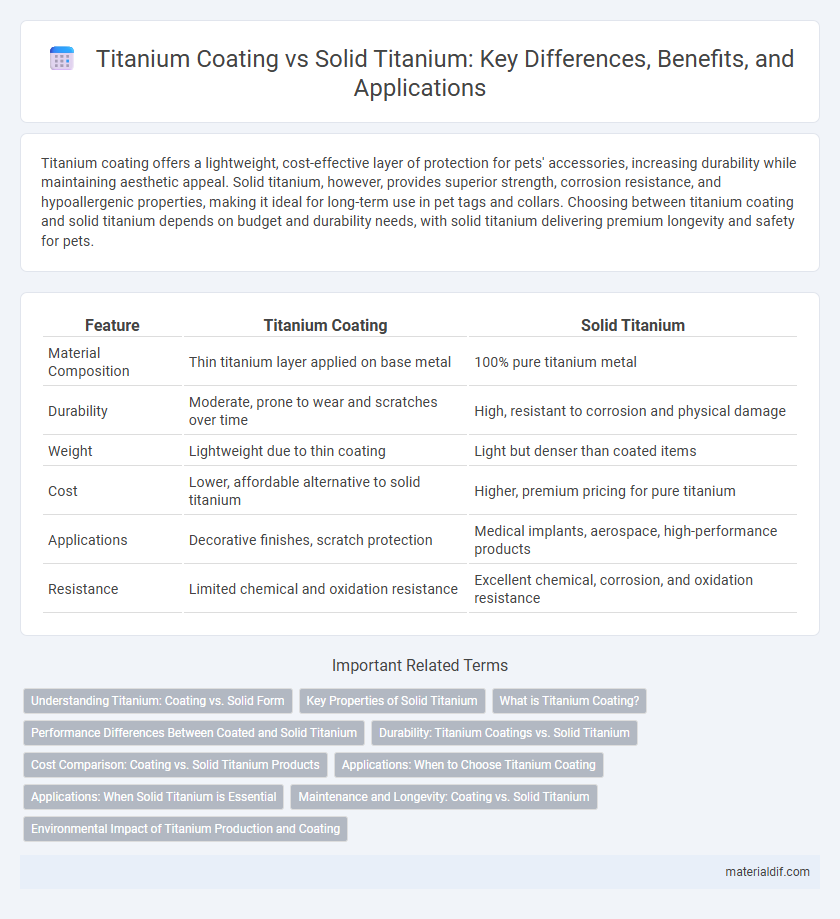

| Feature | Titanium Coating | Solid Titanium |

|---|---|---|

| Material Composition | Thin titanium layer applied on base metal | 100% pure titanium metal |

| Durability | Moderate, prone to wear and scratches over time | High, resistant to corrosion and physical damage |

| Weight | Lightweight due to thin coating | Light but denser than coated items |

| Cost | Lower, affordable alternative to solid titanium | Higher, premium pricing for pure titanium |

| Applications | Decorative finishes, scratch protection | Medical implants, aerospace, high-performance products |

| Resistance | Limited chemical and oxidation resistance | Excellent chemical, corrosion, and oxidation resistance |

Understanding Titanium: Coating vs. Solid Form

Titanium coating provides a thin, protective layer on surfaces, enhancing corrosion resistance and wear durability without significantly increasing weight or cost. Solid titanium offers superior structural strength, biocompatibility, and long-term durability, making it ideal for aerospace and medical implants. Choosing between titanium coating and solid titanium depends on application requirements such as mechanical performance, environmental exposure, and budget constraints.

Key Properties of Solid Titanium

Solid titanium is renowned for its exceptional strength-to-weight ratio, making it highly durable yet lightweight compared to traditional metals. It exhibits outstanding corrosion resistance in harsh environments, preserving its structural integrity over time. Its biocompatibility and high melting point also make solid titanium ideal for medical implants and aerospace applications.

What is Titanium Coating?

Titanium coating is a thin layer of titanium or titanium alloy applied to the surface of another material, typically through processes like physical vapor deposition (PVD) or chemical vapor deposition (CVD). This coating enhances surface properties such as corrosion resistance, hardness, and biocompatibility without the weight or cost associated with solid titanium. Unlike solid titanium, titanium coating provides targeted protection while maintaining the structural integrity of the base material.

Performance Differences Between Coated and Solid Titanium

Titanium coatings offer enhanced surface hardness and corrosion resistance while maintaining the lightweight nature of the substrate, but they may suffer from reduced durability due to potential peeling or wear over time. Solid titanium exhibits superior structural integrity and consistent mechanical performance, making it ideal for high-stress applications requiring long-term reliability. Performance differences hinge on the application demands, with coated titanium beneficial for surface protection and solid titanium preferred for fundamental strength and fatigue resistance.

Durability: Titanium Coatings vs. Solid Titanium

Titanium coatings offer a thin layer of protection that enhances surface hardness and corrosion resistance but may wear off over time due to abrasion or impact. Solid titanium provides inherent durability throughout the entire material, maintaining its strength, corrosion resistance, and lightweight properties even under extreme stress or harsh environments. For long-term applications requiring consistent performance and longevity, solid titanium outperforms titanium coatings in durability and reliability.

Cost Comparison: Coating vs. Solid Titanium Products

Titanium coating offers a cost-effective alternative to solid titanium products by applying a thin layer of titanium onto cheaper base materials, significantly reducing material expenses while maintaining surface durability. Solid titanium products involve higher raw material costs and manufacturing complexities, leading to a substantially increased price point. For industries prioritizing budget without sacrificing corrosion resistance and biocompatibility, coated titanium often provides a financially viable solution compared to solid titanium.

Applications: When to Choose Titanium Coating

Titanium coating is ideal for applications requiring enhanced surface hardness, corrosion resistance, and reduced friction without the added weight or cost of solid titanium components. Industries such as aerospace, automotive, and medical devices often select titanium coatings to improve wear resistance and extend product lifespan while maintaining substrate material properties. Choosing titanium coating is particularly advantageous in tools, surgical instruments, and engine parts where surface performance is critical but bulk material replacement is unnecessary.

Applications: When Solid Titanium is Essential

Solid titanium is essential in aerospace and medical implant applications due to its unmatched strength, biocompatibility, and corrosion resistance that titanium coatings cannot replicate. In structural components subjected to extreme stress and fatigue, solid titanium provides reliable performance without the risk of coating delamination or wear. High-performance industries rely on solid titanium for critical parts where durability and integrity under harsh conditions are paramount.

Maintenance and Longevity: Coating vs. Solid Titanium

Titanium coating offers enhanced surface resistance to scratches and corrosion but may wear off over time, requiring periodic reapplication to maintain its protective properties. Solid titanium, known for its inherent durability and corrosion resistance, provides superior long-term performance with minimal maintenance. Choosing solid titanium ensures a longer lifespan and consistent structural integrity without the need for additional surface treatments.

Environmental Impact of Titanium Production and Coating

Titanium coating minimizes raw material usage and energy consumption compared to solid titanium production, significantly reducing environmental impact. Solid titanium manufacturing involves extensive mining and refining processes that generate high carbon emissions and hazardous waste. Employing titanium coatings on less resource-intensive substrates offers a sustainable alternative by enhancing durability and corrosion resistance with lower ecological footprint.

Titanium Coating vs Solid Titanium Infographic

materialdif.com

materialdif.com