Annealed titanium offers superior flexibility and softness due to its heat-softening process, making it ideal for applications requiring enhanced formability and fatigue resistance in pet products. Heat-treated titanium undergoes a controlled thermal process that increases strength and hardness, providing durability and wear resistance essential for long-lasting pet accessories. Choosing between annealed and heat-treated titanium depends on whether flexibility or strength is the priority in the pet product design.

Table of Comparison

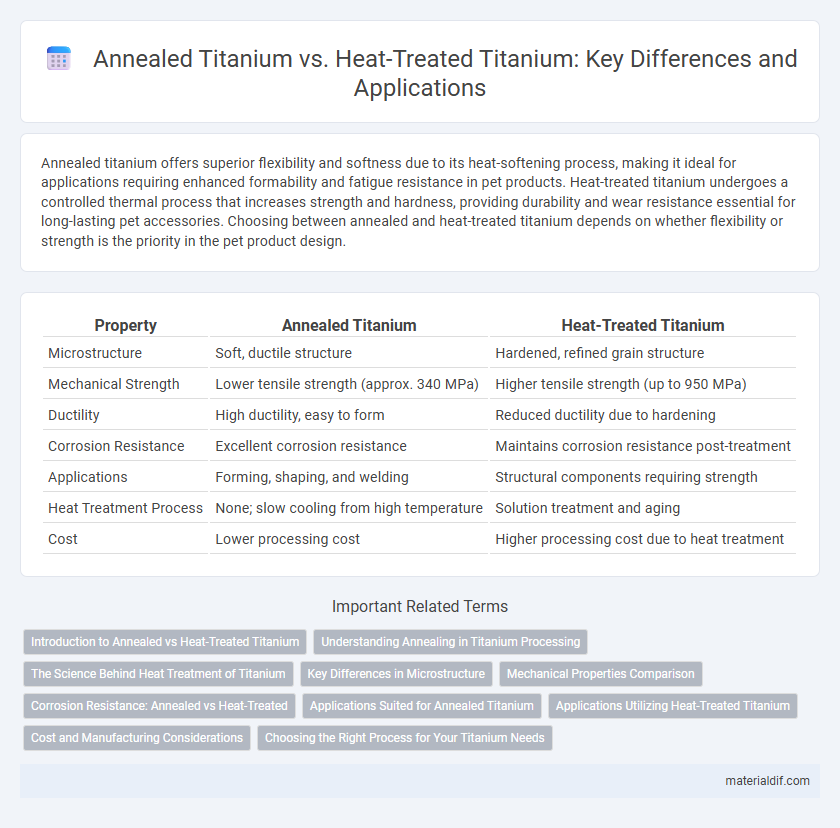

| Property | Annealed Titanium | Heat-Treated Titanium |

|---|---|---|

| Microstructure | Soft, ductile structure | Hardened, refined grain structure |

| Mechanical Strength | Lower tensile strength (approx. 340 MPa) | Higher tensile strength (up to 950 MPa) |

| Ductility | High ductility, easy to form | Reduced ductility due to hardening |

| Corrosion Resistance | Excellent corrosion resistance | Maintains corrosion resistance post-treatment |

| Applications | Forming, shaping, and welding | Structural components requiring strength |

| Heat Treatment Process | None; slow cooling from high temperature | Solution treatment and aging |

| Cost | Lower processing cost | Higher processing cost due to heat treatment |

Introduction to Annealed vs Heat-Treated Titanium

Annealed titanium undergoes a controlled heating and slow cooling process to enhance ductility and reduce internal stresses, making it suitable for applications requiring high formability. Heat-treated titanium, by contrast, is subjected to precise thermal cycles such as solution treating and aging to improve strength, hardness, and fatigue resistance. Understanding the differences between annealed and heat-treated titanium is essential for selecting the appropriate grade and processing method in aerospace, medical, and industrial applications.

Understanding Annealing in Titanium Processing

Annealed titanium undergoes a controlled heating and slow cooling process to relieve internal stresses and improve ductility, making it more workable for forming and shaping. Heat-treated titanium, by contrast, involves specific thermal cycles designed to enhance mechanical properties such as strength and hardness through phase transformations. Understanding annealing is crucial in titanium processing to optimize material performance by achieving a balance between strength and flexibility for aerospace and medical applications.

The Science Behind Heat Treatment of Titanium

The heat treatment of titanium involves controlled heating and cooling processes designed to alter its microstructure, enhancing mechanical properties such as strength, hardness, and fatigue resistance. Annealed titanium retains a soft, ductile microstructure by slow cooling after heating, which improves formability but limits strength. Heat-treated titanium undergoes phases like solution treatment and aging to precipitate alpha-phase structures, optimizing performance for aerospace, medical implants, and high-stress industrial applications.

Key Differences in Microstructure

Annealed titanium exhibits a uniform, equiaxed grain structure resulting from slow cooling, which enhances ductility and machinability. Heat-treated titanium undergoes phase transformations, producing a varied microstructure with increased strength due to the formation of martensitic or alpha-beta phases. These microstructural differences directly impact mechanical properties, making annealed titanium more suitable for forming processes, while heat-treated titanium excels in high-strength applications.

Mechanical Properties Comparison

Annealed titanium exhibits enhanced ductility and toughness due to its recrystallized grain structure, making it ideal for applications requiring high formability. Heat-treated titanium, particularly when subjected to aging processes, shows significantly increased tensile strength and hardness by precipitating strengthening phases within the alloy. The trade-off between annealed and heat-treated titanium lies in balancing improved mechanical strength with decreased plasticity.

Corrosion Resistance: Annealed vs Heat-Treated

Annealed titanium exhibits superior corrosion resistance due to its softer, more uniform microstructure, which minimizes stress and reduces susceptibility to cracking in aggressive environments. Heat-treated titanium, while stronger and harder, may develop microstructural phases that can compromise corrosion resistance under certain conditions. Selecting annealed titanium is often preferred for applications requiring enhanced durability against oxidation and chemical exposure.

Applications Suited for Annealed Titanium

Annealed titanium exhibits excellent ductility and corrosion resistance, making it ideal for biomedical implants, aerospace components, and chemical processing equipment where flexibility and durability are critical. Its softened microstructure allows for intricate forming and machining, suited for precision parts requiring high strength-to-weight ratios. Applications such as surgical instruments and architectural structures benefit from annealed titanium's enhanced toughness and ability to withstand cyclic stresses.

Applications Utilizing Heat-Treated Titanium

Heat-treated titanium offers enhanced strength and improved fatigue resistance, making it ideal for aerospace components, medical implants, and high-performance automotive parts. Its superior mechanical properties allow for use in demanding environments where durability and weight reduction are critical. Applications such as jet engine parts, surgical tools, and race car frames benefit significantly from the structural advantages provided by heat-treated titanium.

Cost and Manufacturing Considerations

Annealed titanium generally costs less due to simpler manufacturing processes involving controlled slow cooling to reduce hardness and improve ductility. Heat-treated titanium undergoes precise temperature cycles, increasing strength and fatigue resistance but raising production expenses because of extended processing times and specialized equipment. Manufacturers balance cost against performance benefits, choosing annealed titanium for applications prioritizing flexibility and cost-efficiency, while heat-treated titanium suits high-stress environments demanding superior mechanical properties.

Choosing the Right Process for Your Titanium Needs

Annealed titanium offers enhanced ductility and improved machinability, making it ideal for applications requiring complex forming or shaping. Heat-treated titanium delivers superior strength and hardness, suitable for aerospace, medical implants, and high-stress environments. Selecting between annealed and heat-treated titanium depends on balancing mechanical properties with specific performance demands in your project.

Annealed Titanium vs Heat-Treated Titanium Infographic

materialdif.com

materialdif.com