Pickled titanium undergoes a chemical treatment that removes surface impurities and enhances corrosion resistance, resulting in a matte, non-reflective finish ideal for industrial uses. Polished titanium features a smooth, shiny surface achieved through mechanical polishing, offering an aesthetically appealing and easy-to-clean option often preferred for decorative or medical applications. Both finishes maintain titanium's exceptional strength-to-weight ratio and biocompatibility, with the choice depending on specific functional or visual requirements.

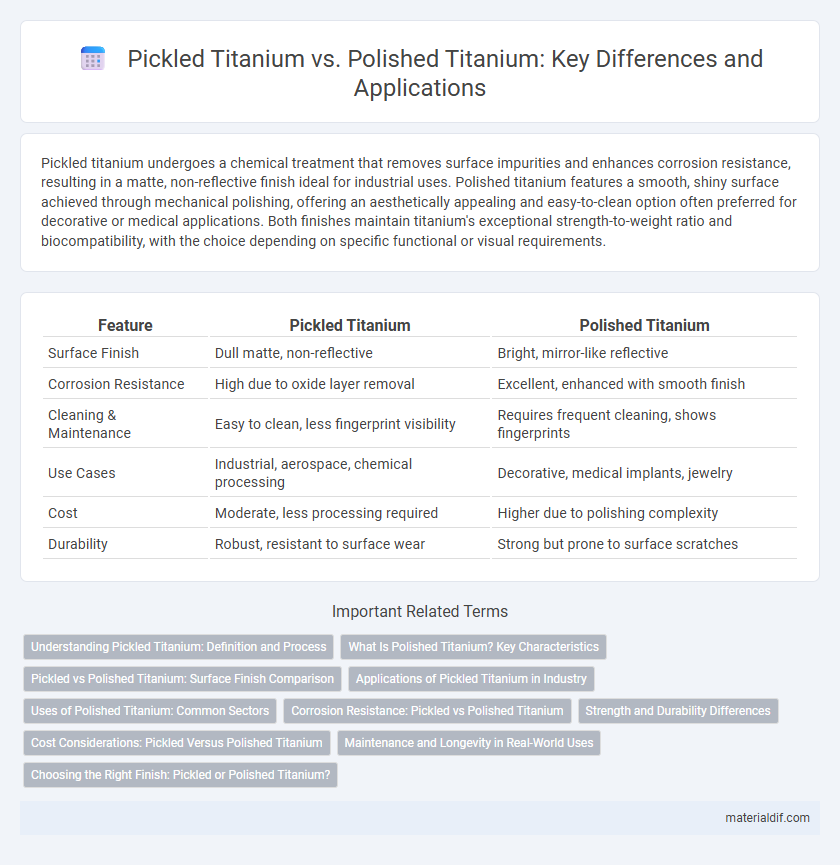

Table of Comparison

| Feature | Pickled Titanium | Polished Titanium |

|---|---|---|

| Surface Finish | Dull matte, non-reflective | Bright, mirror-like reflective |

| Corrosion Resistance | High due to oxide layer removal | Excellent, enhanced with smooth finish |

| Cleaning & Maintenance | Easy to clean, less fingerprint visibility | Requires frequent cleaning, shows fingerprints |

| Use Cases | Industrial, aerospace, chemical processing | Decorative, medical implants, jewelry |

| Cost | Moderate, less processing required | Higher due to polishing complexity |

| Durability | Robust, resistant to surface wear | Strong but prone to surface scratches |

Understanding Pickled Titanium: Definition and Process

Pickled titanium refers to titanium that has undergone a chemical treatment process using acid solutions to remove surface impurities, oxides, and discoloration, resulting in a clean, matte finish. This process enhances the metal's corrosion resistance and prepares it for further fabrication or coating. Unlike polished titanium, which is mechanically buffed to achieve a shiny, reflective surface, pickled titanium maintains a uniform, non-reflective texture ideal for industrial and medical applications.

What Is Polished Titanium? Key Characteristics

Polished titanium is a finished form of titanium metal characterized by its smooth, reflective surface achieved through mechanical or chemical polishing processes. This process enhances titanium's natural corrosion resistance and biocompatibility, making it ideal for medical implants, jewelry, and aerospace applications. Polished titanium exhibits increased surface hardness and reduced friction, contributing to its durability and aesthetic appeal.

Pickled vs Polished Titanium: Surface Finish Comparison

Pickled titanium features a chemically treated surface that removes impurities and provides a matte, non-reflective finish, enhancing corrosion resistance and cleanliness. Polished titanium undergoes mechanical abrasion and buffing to create a smooth, reflective, and aesthetically appealing surface with high gloss. The choice between pickled and polished titanium depends on application requirements for appearance, corrosion protection, and surface texture.

Applications of Pickled Titanium in Industry

Pickled titanium, treated with acid solutions to remove surface impurities, offers enhanced corrosion resistance and surface uniformity, making it ideal for chemical processing equipment and marine applications. Its improved cleanliness and durability extend the lifespan of heat exchangers, storage tanks, and piping systems in harsh industrial environments. Industries such as aerospace and medical devices also utilize pickled titanium for components requiring reliable performance under extreme conditions.

Uses of Polished Titanium: Common Sectors

Polished titanium is extensively used in the aerospace industry due to its high strength-to-weight ratio and corrosion resistance, making it ideal for aircraft components and engine parts. In the medical field, its biocompatibility and smooth finish support applications in surgical instruments, implants, and dental devices. Additionally, polished titanium's aesthetic appeal and durability make it popular in luxury watches, jewelry, and consumer electronics.

Corrosion Resistance: Pickled vs Polished Titanium

Pickled titanium exhibits superior corrosion resistance due to the removal of surface contaminants and oxide layers, which enhances passive film formation and protects the metal from aggressive environments. Polished titanium, while aesthetically appealing with its smooth finish, may have micro-scratches that can compromise the protective oxide layer, making it slightly more vulnerable to localized corrosion. The chemical treatment in pickling processes ensures a uniformly clean surface, resulting in enhanced durability and longer service life in corrosive applications compared to mechanically polished titanium.

Strength and Durability Differences

Pickled titanium undergoes an acid treatment that enhances its corrosion resistance by removing surface impurities, leading to a slightly increased strength due to a cleaner metal surface. Polished titanium, while aesthetically smoother and mirror-like, maintains high tensile strength but can be more susceptible to surface scratches and minor fatigue over time. Both finishes retain titanium's inherent durability, but pickled titanium offers superior resilience in harsh environments due to its enhanced protective oxide layer.

Cost Considerations: Pickled Versus Polished Titanium

Pickled titanium typically incurs lower processing costs due to its simpler acid treatment that removes surface impurities without additional finishing steps. Polished titanium requires extensive mechanical or electro-polishing processes, increasing labor and equipment expenses. Businesses must weigh the functional and aesthetic benefits of polished titanium against the cost-efficiency and corrosion resistance of pickled surfaces.

Maintenance and Longevity in Real-World Uses

Pickled titanium features a chemically treated surface that offers enhanced corrosion resistance, requiring minimal maintenance and preserving its integrity in harsh environments. Polished titanium, while visually appealing with a smooth, reflective finish, demands more frequent cleaning to prevent surface scratches and maintain its luster over time. In real-world applications, pickled titanium excels in durability and long-term performance, especially in industrial and marine settings, whereas polished titanium suits aesthetic-driven uses where appearance is prioritized.

Choosing the Right Finish: Pickled or Polished Titanium?

Pickled titanium features a matte, uniform surface achieved through acid treatment that enhances corrosion resistance and removes impurities, making it ideal for industrial applications requiring durability. Polished titanium offers a bright, reflective finish that highlights the metal's natural luster, preferred in jewelry and decorative uses for its aesthetic appeal. Selecting between pickled or polished titanium depends on the desired balance between functional protection and visual elegance.

Pickled Titanium vs Polished Titanium Infographic

materialdif.com

materialdif.com