ASTM B348 and AMS 4928 are key specifications for titanium materials used in pet products, ensuring high-quality and reliable performance. ASTM B348 defines the chemical and mechanical properties for titanium and titanium alloy bars, rods, and billets, while AMS 4928 focuses on seamless titanium tubing with stringent requirements for aerospace and high-performance applications. Choosing between ASTM B348 and AMS 4928 depends on the specific pet product design, with ASTM B348 typically preferred for solid components and AMS 4928 for tubular structures requiring exceptional strength and corrosion resistance.

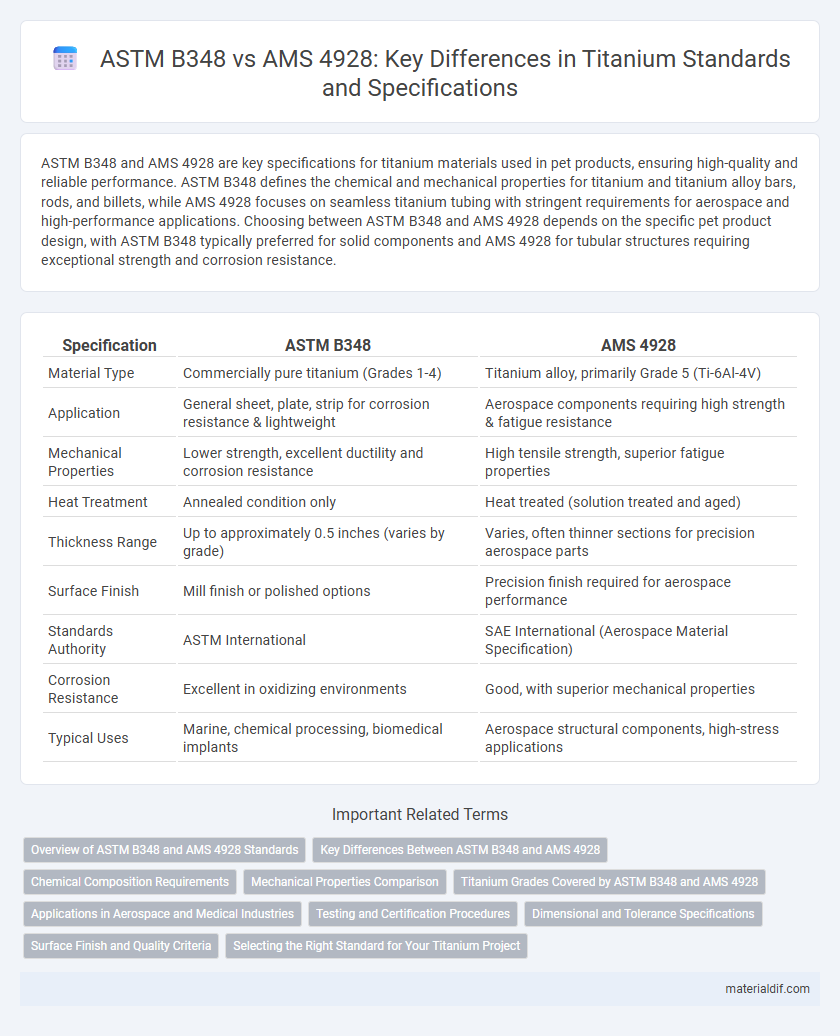

Table of Comparison

| Specification | ASTM B348 | AMS 4928 |

|---|---|---|

| Material Type | Commercially pure titanium (Grades 1-4) | Titanium alloy, primarily Grade 5 (Ti-6Al-4V) |

| Application | General sheet, plate, strip for corrosion resistance & lightweight | Aerospace components requiring high strength & fatigue resistance |

| Mechanical Properties | Lower strength, excellent ductility and corrosion resistance | High tensile strength, superior fatigue properties |

| Heat Treatment | Annealed condition only | Heat treated (solution treated and aged) |

| Thickness Range | Up to approximately 0.5 inches (varies by grade) | Varies, often thinner sections for precision aerospace parts |

| Surface Finish | Mill finish or polished options | Precision finish required for aerospace performance |

| Standards Authority | ASTM International | SAE International (Aerospace Material Specification) |

| Corrosion Resistance | Excellent in oxidizing environments | Good, with superior mechanical properties |

| Typical Uses | Marine, chemical processing, biomedical implants | Aerospace structural components, high-stress applications |

Overview of ASTM B348 and AMS 4928 Standards

ASTM B348 specifies requirements for titanium and titanium alloy bars for aerospace and general engineering applications, emphasizing chemical composition, mechanical properties, and microstructure controls. AMS 4928 focuses on titanium alloy bars with stricter tolerances, enhanced testing protocols, and traceability primarily for critical aerospace components. Both standards ensure high-performance titanium products but differ in scope, quality assurance, and application specificity.

Key Differences Between ASTM B348 and AMS 4928

ASTM B348 specifies the standard for titanium and titanium alloy bars used in aerospace applications, focusing on chemical composition, mechanical properties, and manufacturing processes for commercial-grade titanium. AMS 4928 covers titanium alloy bars with more stringent requirements for aerospace-quality materials, including tighter controls on metallurgy, microstructure, and mechanical testing for high-performance applications. Key differences include AMS 4928's emphasis on enhanced mechanical properties and traceability compared to ASTM B348, making AMS 4928 suitable for critical aerospace components requiring superior performance and reliability.

Chemical Composition Requirements

ASTM B348 specifies chemical composition requirements for commercially pure titanium grades such as Grade 1, 2, 3, and 4, ensuring limits on elements like oxygen, nitrogen, iron, and carbon to maintain specified mechanical properties. AMS 4928 covers titanium alloy bars, focusing on precise control of alloying elements like aluminum, vanadium, and iron to meet strength and corrosion resistance standards in aerospace applications. The stricter and more detailed chemical composition criteria in AMS 4928 support higher-performance titanium alloys compared to the broader compositional ranges allowed in ASTM B348.

Mechanical Properties Comparison

ASTM B348 specifies titanium and titanium alloy raw materials primarily for industrial use, offering minimum tensile strengths ranging from 70 ksi to 138 ksi depending on the grade. AMS 4928, tailored for aerospace applications, ensures stricter mechanical property controls with tensile strengths commonly exceeding 130 ksi and improved yield strength and elongation standards for enhanced fatigue resistance. The AMS 4928 standard demands tighter quality assurance, resulting in superior mechanical performance critical for aerospace structural components compared to the broader ASTM B348 specification.

Titanium Grades Covered by ASTM B348 and AMS 4928

ASTM B348 specifies titanium grades such as Grade 1, Grade 2, Grade 5 (Ti-6Al-4V), and Grade 9 (Ti-3Al-2.5V) primarily for seamless drawn tube products. AMS 4928 mainly covers titanium alloy Grade 5 (Ti-6Al-4V) in various product forms, including bars and forgings, with stringent requirements for aerospace applications. The selection between ASTM B348 and AMS 4928 depends on the specific titanium grade needed and the intended application, with ASTM B348 providing broader grade coverage for general industrial use.

Applications in Aerospace and Medical Industries

ASTM B348 titanium is widely used in aerospace applications for structural components and fasteners due to its high strength-to-weight ratio and excellent corrosion resistance. AMS 4928 titanium, with its tighter tolerances and superior mechanical properties, is preferred in medical implants and surgical instruments requiring biocompatibility and precise performance. Both standards ensure reliable titanium materials, but AMS 4928 is specifically optimized for critical aerospace and medical industry requirements.

Testing and Certification Procedures

ASTM B348 specifies the chemical composition and mechanical properties for titanium and titanium alloy bars, emphasizing tensile testing and hardness measurements to ensure material integrity. AMS 4928 outlines more stringent testing and certification procedures, including detailed heat treatment verification and ultrasonic flaw detection to guarantee aerospace-grade quality. Certification under AMS 4928 typically requires traceability documentation and compliance with rigorous aerospace standards, whereas ASTM B348 focuses on general commercial quality control.

Dimensional and Tolerance Specifications

ASTM B348 specifies tight dimensional and tolerance requirements for commercially pure titanium bars, sheets, and plates, ensuring precise thickness, width, and length tolerances critical for aerospace and medical applications. AMS 4928 focuses on titanium alloy billets and bars with stringent dimensional control, emphasizing tighter tolerances in diameter and length to meet high-performance engineering standards. Both standards prioritize maintaining consistent dimensions and minimal deviations to guarantee material integrity and fit during manufacturing processes.

Surface Finish and Quality Criteria

ASTM B348 titanium specifies a smooth surface finish with stringent controls on cleanliness, surface defects, and dimensional tolerances to ensure high-quality raw material for aerospace and industrial applications. AMS 4928 emphasizes advanced surface finish criteria, requiring enhanced uniformity and freedom from imperfections through precise metallurgical quality standards and inspection protocols. Both standards prioritize superior surface integrity but AMS 4928 is often preferred for critical aerospace components demanding rigorous quality control and traceability documentation.

Selecting the Right Standard for Your Titanium Project

ASTM B348 and AMS 4928 are critical standards for titanium selection, with ASTM B348 focusing on titanium and titanium alloy bars, billets, and forgings primarily used in structural and aerospace applications. AMS 4928 specifies requirements for titanium alloy sheets, plates, and strips, tailored for high-strength, corrosion-resistant components in aerospace and medical industries. Understanding the material form, mechanical properties, and end-use environment is essential to choose the correct standard, ensuring compliance, performance, and safety in your titanium project.

ASTM B348 vs AMS 4928 Infographic

materialdif.com

materialdif.com