Titanium fasteners offer superior corrosion resistance, lightweight strength, and high tensile strength, making them ideal for demanding applications. Compared to titanium bolts, fasteners encompass a broader range of designs including screws, nuts, and washers, providing versatile fastening solutions. Both are prized in aerospace, marine, and automotive industries for their durability and resistance to extreme environments.

Table of Comparison

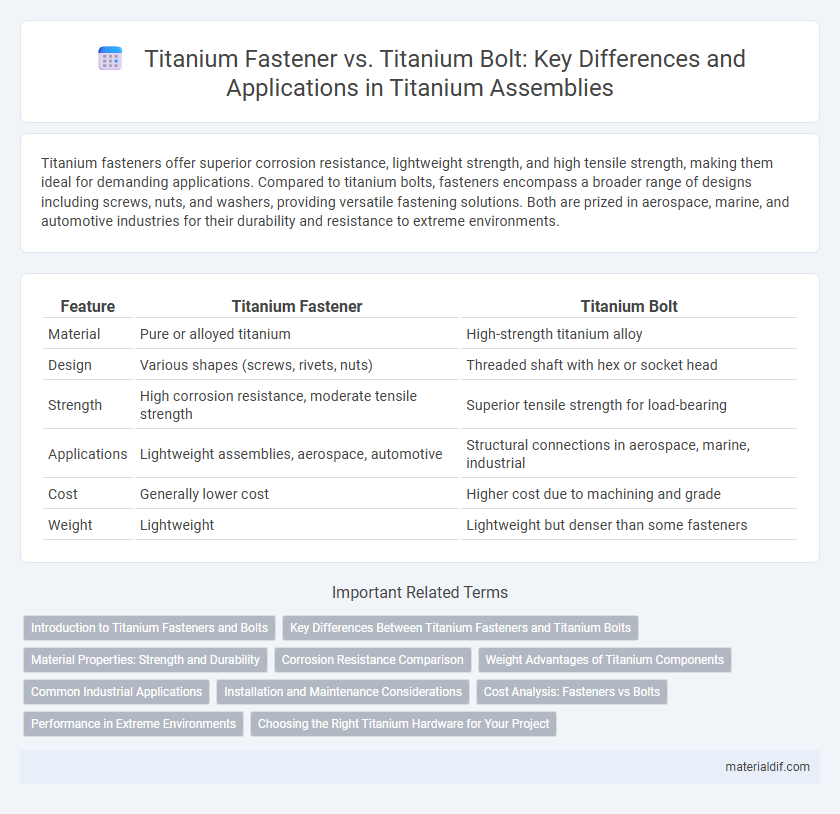

| Feature | Titanium Fastener | Titanium Bolt |

|---|---|---|

| Material | Pure or alloyed titanium | High-strength titanium alloy |

| Design | Various shapes (screws, rivets, nuts) | Threaded shaft with hex or socket head |

| Strength | High corrosion resistance, moderate tensile strength | Superior tensile strength for load-bearing |

| Applications | Lightweight assemblies, aerospace, automotive | Structural connections in aerospace, marine, industrial |

| Cost | Generally lower cost | Higher cost due to machining and grade |

| Weight | Lightweight | Lightweight but denser than some fasteners |

Introduction to Titanium Fasteners and Bolts

Titanium fasteners and bolts are essential components in aerospace, automotive, and marine industries due to their exceptional strength-to-weight ratio and corrosion resistance. Titanium fasteners encompass a variety of fastening devices such as screws, nuts, and washers, while titanium bolts specifically refer to cylindrical threaded rods designed for high-strength joint applications. Their biocompatibility and durability under extreme conditions make titanium bolts and fasteners ideal for critical structural and mechanical assemblies.

Key Differences Between Titanium Fasteners and Titanium Bolts

Titanium fasteners encompass a broad category of hardware, including screws, rivets, nuts, and bolts, designed for lightweight strength and corrosion resistance in aerospace, automotive, and medical industries. Titanium bolts specifically refer to threaded fasteners with hexagonal heads, providing high tensile strength and securing components under significant stress in high-performance applications. The key differences lie in their design and function: fasteners cover various types and applications, while bolts are a subset focused on load-bearing and structural integrity with precise torque specifications.

Material Properties: Strength and Durability

Titanium fasteners and titanium bolts both exhibit exceptional strength-to-weight ratios and superior corrosion resistance due to the metal's innate properties. Titanium bolts often undergo precision forging or machining to enhance tensile strength, making them ideal for high-stress applications in aerospace and automotive industries. The durability of titanium fasteners ensures long-lasting performance in extreme environments, driven by titanium's high fatigue resistance and ability to withstand cyclic loading without compromising structural integrity.

Corrosion Resistance Comparison

Titanium fasteners exhibit superior corrosion resistance compared to titanium bolts due to their finer grain structure and specialized surface treatments that enhance durability in harsh environments. While both titanium fasteners and bolts resist oxidation and chemical degradation, fasteners often undergo additional anodizing processes that improve their lifespan in marine and industrial applications. The enhanced corrosion resistance of titanium fasteners ensures reliable performance in exposure to saltwater, acids, and extreme temperatures, making them preferable for critical aerospace and automotive uses.

Weight Advantages of Titanium Components

Titanium fasteners offer significant weight advantages compared to traditional steel bolts, with up to 45% lighter mass while maintaining high tensile strength. This weight reduction enhances performance in aerospace and automotive applications by improving fuel efficiency and reducing structural load. Titanium bolts, known for their corrosion resistance, provide durable, lightweight solutions critical for high-performance engineering designs.

Common Industrial Applications

Titanium fasteners and titanium bolts are widely used in aerospace, automotive, and marine industries due to their exceptional strength-to-weight ratio and corrosion resistance. Titanium bolts are specifically favored in high-stress environments such as aircraft engines and structural components, where precise torque and durability are critical. Titanium fasteners, including screws and rivets, find common applications in electronic enclosures and chemical processing equipment, offering reliable performance under extreme conditions.

Installation and Maintenance Considerations

Titanium fasteners generally offer easier installation due to their lightweight nature and corrosion resistance, reducing the need for extensive surface preparation and anti-seize lubricants compared to standard titanium bolts. Titanium bolts, often designed for high-strength applications, require precise torque settings during installation to prevent galling and ensure optimal performance. Maintenance for both fasteners and bolts includes regular inspection for signs of stress corrosion cracking, but titanium's inherent durability minimizes frequent replacements and upkeep.

Cost Analysis: Fasteners vs Bolts

Titanium fasteners typically incur a higher upfront cost compared to standard titanium bolts due to their specialized manufacturing processes and precision engineering. Fasteners often involve complex threading and surface treatments that increase production expenses, whereas titanium bolts are generally simpler in design and cheaper to produce. Evaluating lifecycle costs, titanium fasteners may offer better corrosion resistance and strength, potentially reducing long-term maintenance and replacement expenses compared to titanium bolts.

Performance in Extreme Environments

Titanium fasteners exhibit superior corrosion resistance and strength-to-weight ratio, making them ideal for extreme environments such as aerospace and marine applications. Titanium bolts provide enhanced tensile strength and fatigue resistance, crucial for high-stress conditions in automotive and industrial machinery. Both fasteners outperform traditional steel counterparts by maintaining integrity under high temperatures and aggressive chemical exposure.

Choosing the Right Titanium Hardware for Your Project

Selecting the right titanium hardware requires understanding the differences between titanium fasteners and titanium bolts, as fasteners include a broad category encompassing screws, nuts, and washers, while bolts specifically refer to threaded fasteners designed for high-strength joint applications. Titanium bolts offer superior tensile strength and corrosion resistance, ideal for structural projects demanding durability under stress, whereas titanium fasteners provide versatility across various fastening needs with lightweight and non-magnetic properties. Evaluating the mechanical requirements, environmental conditions, and load factors helps ensure that the chosen titanium hardware maximizes performance and longevity in aerospace, automotive, or marine applications.

Titanium Fastener vs Titanium Bolt Infographic

materialdif.com

materialdif.com