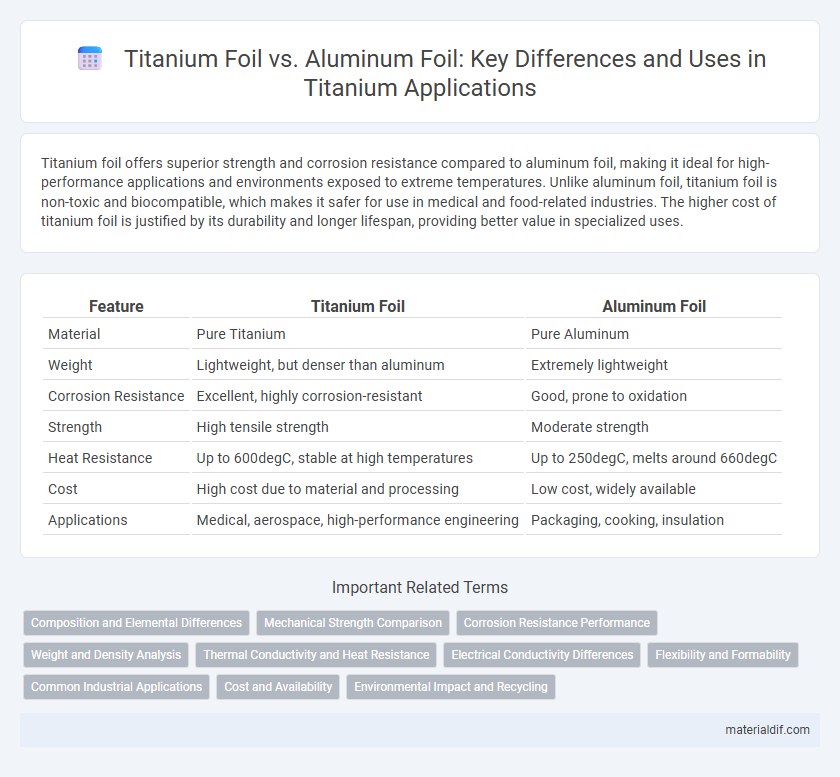

Titanium foil offers superior strength and corrosion resistance compared to aluminum foil, making it ideal for high-performance applications and environments exposed to extreme temperatures. Unlike aluminum foil, titanium foil is non-toxic and biocompatible, which makes it safer for use in medical and food-related industries. The higher cost of titanium foil is justified by its durability and longer lifespan, providing better value in specialized uses.

Table of Comparison

| Feature | Titanium Foil | Aluminum Foil |

|---|---|---|

| Material | Pure Titanium | Pure Aluminum |

| Weight | Lightweight, but denser than aluminum | Extremely lightweight |

| Corrosion Resistance | Excellent, highly corrosion-resistant | Good, prone to oxidation |

| Strength | High tensile strength | Moderate strength |

| Heat Resistance | Up to 600degC, stable at high temperatures | Up to 250degC, melts around 660degC |

| Cost | High cost due to material and processing | Low cost, widely available |

| Applications | Medical, aerospace, high-performance engineering | Packaging, cooking, insulation |

Composition and Elemental Differences

Titanium foil consists primarily of titanium, a strong, corrosion-resistant metal with a high melting point, whereas aluminum foil is made from aluminum, a lighter and more malleable metal with excellent thermal and electrical conductivity. Titanium's atomic number is 22, featuring a dense atomic structure that contributes to its superior strength and oxidative resistance compared to aluminum's atomic number 13 and its more reactive nature. The elemental composition differences result in titanium foil being more suitable for applications requiring durability and heat resistance, while aluminum foil is preferred for lightweight packaging and thermal insulation.

Mechanical Strength Comparison

Titanium foil exhibits significantly higher mechanical strength compared to aluminum foil, with a tensile strength ranging from 434 to 1,400 MPa, while aluminum foil typically ranges between 70 to 700 MPa. This superior strength allows titanium foil to withstand greater stress and deformation, making it ideal for aerospace and medical applications requiring durability and corrosion resistance. Despite being thicker and heavier, titanium foil's high strength-to-weight ratio contributes to enhanced performance in load-bearing environments.

Corrosion Resistance Performance

Titanium foil offers superior corrosion resistance compared to aluminum foil, especially in harsh environments such as saltwater and acidic conditions. Its passive oxide layer provides excellent protection against oxidation and pitting, making it ideal for marine and chemical applications. Aluminum foil tends to corrode more quickly, particularly when exposed to moisture and electrolytes, limiting its durability in corrosive settings.

Weight and Density Analysis

Titanium foil exhibits a significantly lower density of approximately 4.5 g/cm3 compared to aluminum foil's density of 2.7 g/cm3, resulting in a higher weight for titanium foil at equivalent thicknesses. Despite titanium's greater weight, its superior strength-to-weight ratio enables thinner foils to achieve similar or enhanced durability and corrosion resistance compared to aluminum. This weight and density analysis is critical when selecting materials for aerospace, medical, and industrial applications where performance and weight optimization are paramount.

Thermal Conductivity and Heat Resistance

Titanium foil exhibits significantly lower thermal conductivity compared to aluminum foil, making it more effective for applications requiring heat retention and insulation. Titanium's high melting point of approximately 1,668degC offers superior heat resistance, whereas aluminum foil melts at around 660degC, limiting its use in extreme temperature environments. This thermal durability makes titanium foil ideal for aerospace, medical, and industrial uses where high heat resistance is critical.

Electrical Conductivity Differences

Titanium foil exhibits significantly lower electrical conductivity compared to aluminum foil, with titanium's conductivity around 2.38 million S/m versus aluminum's approximately 37.7 million S/m. This difference makes aluminum foil more suitable for applications requiring efficient electrical current flow, whereas titanium foil is preferred for its strength and corrosion resistance despite its lower conductivity. The disparity in electrical properties is due to the distinct atomic structures and electron mobility in each metal.

Flexibility and Formability

Titanium foil exhibits superior flexibility and formability compared to aluminum foil due to its high strength-to-weight ratio and excellent ductility, allowing it to endure more complex bending and shaping processes without cracking. Aluminum foil is more prone to tearing during extensive manipulation, while titanium foil maintains its integrity in applications requiring intricate forming. This makes titanium foil ideal for aerospace, medical, and high-performance industrial uses where precise and durable material shaping is critical.

Common Industrial Applications

Titanium foil offers superior corrosion resistance and high strength-to-weight ratio compared to aluminum foil, making it ideal for aerospace components, chemical processing equipment, and medical implants. Aluminum foil remains prevalent in packaging, insulation, and lightweight heat exchangers due to its excellent malleability and cost-effectiveness. Industrial sectors prefer titanium foil for applications requiring durability under extreme conditions, whereas aluminum foil suits low-cost, high-volume uses.

Cost and Availability

Titanium foil generally costs significantly more than aluminum foil due to the complex extraction and processing required for titanium metal. Availability of titanium foil is more limited and usually confined to specialized industrial and aerospace suppliers, whereas aluminum foil is widely available and inexpensive for everyday use. The price difference and supply constraints make aluminum foil the preferred choice for most applications where cost efficiency is critical.

Environmental Impact and Recycling

Titanium foil exhibits a significantly lower environmental impact compared to aluminum foil due to its longer lifespan and resistance to corrosion, reducing waste generation. Its recycling process, although energy-intensive, benefits from high material recovery rates and maintains titanium's durability without degradation. Aluminum foil recycling requires substantial energy and often results in downcycling, leading to decreased material quality and increased demand for raw aluminum extraction, which further elevates environmental burdens.

Titanium Foil vs Aluminum Foil Infographic

materialdif.com

materialdif.com