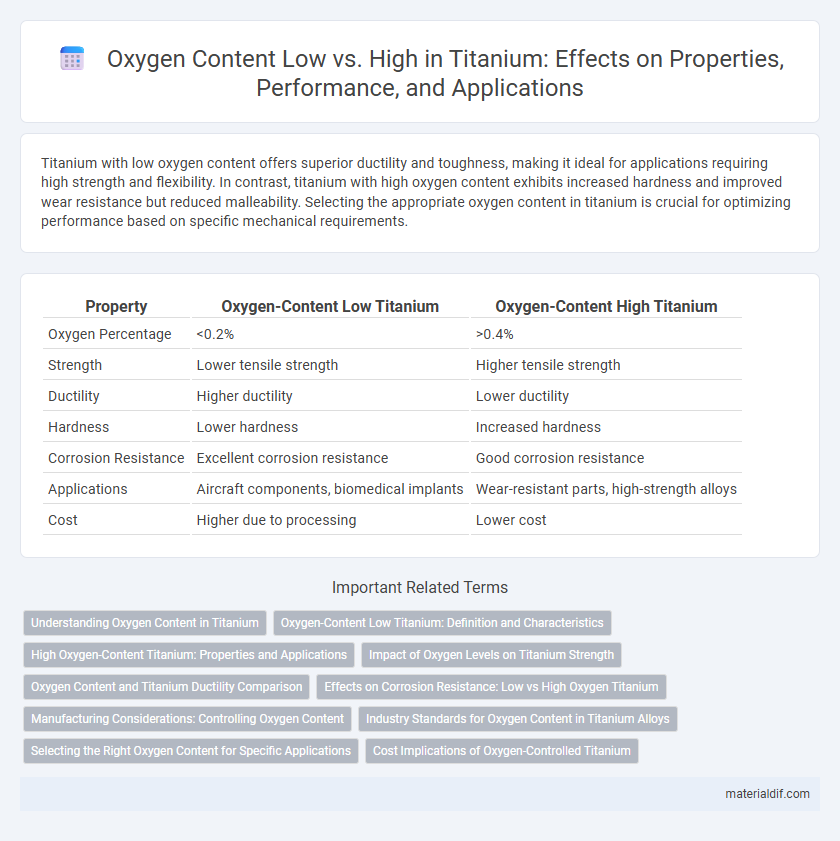

Titanium with low oxygen content offers superior ductility and toughness, making it ideal for applications requiring high strength and flexibility. In contrast, titanium with high oxygen content exhibits increased hardness and improved wear resistance but reduced malleability. Selecting the appropriate oxygen content in titanium is crucial for optimizing performance based on specific mechanical requirements.

Table of Comparison

| Property | Oxygen-Content Low Titanium | Oxygen-Content High Titanium |

|---|---|---|

| Oxygen Percentage | <0.2% | >0.4% |

| Strength | Lower tensile strength | Higher tensile strength |

| Ductility | Higher ductility | Lower ductility |

| Hardness | Lower hardness | Increased hardness |

| Corrosion Resistance | Excellent corrosion resistance | Good corrosion resistance |

| Applications | Aircraft components, biomedical implants | Wear-resistant parts, high-strength alloys |

| Cost | Higher due to processing | Lower cost |

Understanding Oxygen Content in Titanium

Oxygen content in titanium significantly influences its mechanical properties, where low oxygen titanium retains higher ductility and toughness, making it ideal for aerospace and medical applications. High oxygen titanium increases strength and hardness but reduces formability and fracture resistance, suitable for structural components requiring enhanced durability. Controlling oxygen levels during processing is critical to optimize performance characteristics and ensure material reliability in demanding environments.

Oxygen-Content Low Titanium: Definition and Characteristics

Oxygen-content low titanium, typically containing less than 0.20% oxygen, is valued for its superior ductility, toughness, and corrosion resistance compared to higher oxygen variants. This grade of titanium exhibits enhanced performance in aerospace and biomedical applications due to reduced interstitial oxygen atoms, which minimize embrittlement and maintain the metal's intrinsic strength and malleability. Control of oxygen levels within this range ensures optimal mechanical properties while preserving titanium's lightweight and high-strength characteristics.

High Oxygen-Content Titanium: Properties and Applications

High oxygen-content titanium exhibits increased hardness, strength, and wear resistance, making it ideal for aerospace components, medical implants, and high-performance automotive parts. Despite reduced ductility compared to low oxygen-content titanium, its enhanced oxidation resistance and fatigue strength enable superior performance in high-temperature and corrosive environments. This combination of properties optimizes high oxygen-content titanium for demanding structural applications where durability and reliability are critical.

Impact of Oxygen Levels on Titanium Strength

Oxygen content in titanium significantly affects its mechanical properties, with low-oxygen titanium exhibiting higher ductility and toughness, while high-oxygen titanium offers increased strength and hardness due to solid solution strengthening. Optimal oxygen levels balance enhanced tensile strength without compromising fracture resistance, critical in aerospace and biomedical applications. Controlling oxygen impurities during processing ensures titanium alloys meet specific strength and performance criteria for demanding environments.

Oxygen Content and Titanium Ductility Comparison

Titanium with low oxygen content typically exhibits higher ductility, enabling better formability and resistance to cracking under stress. High oxygen content in titanium significantly increases strength and hardness but reduces ductility, making the alloy more brittle and less workable. Optimizing oxygen levels is crucial for balancing mechanical performance, particularly in aerospace and biomedical applications where both toughness and strength are essential.

Effects on Corrosion Resistance: Low vs High Oxygen Titanium

Low oxygen-content titanium exhibits superior corrosion resistance due to its enhanced purity, resulting in fewer oxide inclusions and a more uniform passive oxide layer. High oxygen-content titanium, conversely, tends to form a thicker but less stable oxide film, increasing susceptibility to localized corrosion and embrittlement. This difference in oxygen content critically impacts titanium's performance in aggressive environments, making low oxygen variants preferable for marine and chemical applications.

Manufacturing Considerations: Controlling Oxygen Content

Controlling oxygen content in titanium manufacturing is critical for mechanical properties and corrosion resistance, where low oxygen levels below 0.15% enhance ductility and toughness, while high oxygen content above 0.25% increases strength but reduces fatigue performance. Advanced vacuum arc remelting and electron beam melting techniques enable precise adjustment of oxygen content, minimizing contamination during processing. Continuous monitoring with inert gas environments and rigorous quality control protocols ensures optimal oxygen control, preventing embrittlement and maintaining alloy consistency.

Industry Standards for Oxygen Content in Titanium Alloys

Industry standards for oxygen content in titanium alloys typically range from 0.10% to 0.40% by weight, with low-oxygen titanium alloys containing less than 0.15% oxygen to enhance ductility and fracture toughness. High-oxygen titanium alloys, often exceeding 0.25% oxygen, are generally utilized for applications requiring improved strength and hardness, though with a trade-off in reduced ductility. Precise control of oxygen content is regulated by ASTM and ISO specifications to ensure performance consistency in aerospace, medical, and automotive industries.

Selecting the Right Oxygen Content for Specific Applications

Selecting the right oxygen content in titanium is crucial for achieving optimal mechanical properties and corrosion resistance tailored to specific applications. Low oxygen-content titanium offers superior ductility and toughness, making it ideal for aerospace components and biomedical implants requiring high strength-to-weight ratios and biocompatibility. High oxygen-content titanium provides increased hardness and wear resistance suited for industrial tools and automotive parts subject to abrasive environments.

Cost Implications of Oxygen-Controlled Titanium

Oxygen-controlled titanium with low oxygen content typically incurs higher production costs due to more stringent refining processes and specialized equipment required to limit oxygen levels. High oxygen-content titanium offers cost advantages by utilizing less intensive processing methods but may compromise mechanical properties, impacting its suitability for critical applications. Balancing oxygen content is essential for optimizing cost efficiency while maintaining desired material performance in aerospace and medical industries.

Oxygen-Content Low vs Oxygen-Content High Infographic

materialdif.com

materialdif.com