SPF Titanium forming offers superior precision and structural integrity compared to traditional titanium stamping, resulting in stronger and more durable pet components. This method reduces material waste and enhances geometric accuracy by utilizing advanced superplastic forming techniques. Manufacturers benefit from improved consistency and reduced production costs with SPF titanium forming over conventional stamping processes.

Table of Comparison

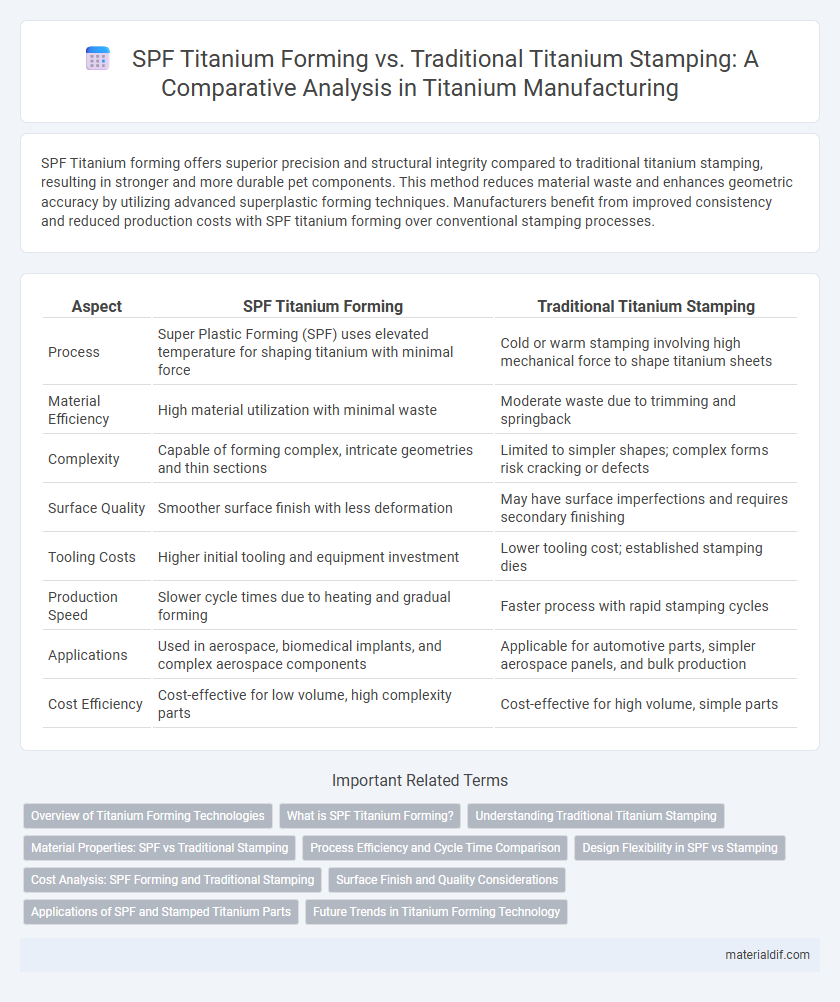

| Aspect | SPF Titanium Forming | Traditional Titanium Stamping |

|---|---|---|

| Process | Super Plastic Forming (SPF) uses elevated temperature for shaping titanium with minimal force | Cold or warm stamping involving high mechanical force to shape titanium sheets |

| Material Efficiency | High material utilization with minimal waste | Moderate waste due to trimming and springback |

| Complexity | Capable of forming complex, intricate geometries and thin sections | Limited to simpler shapes; complex forms risk cracking or defects |

| Surface Quality | Smoother surface finish with less deformation | May have surface imperfections and requires secondary finishing |

| Tooling Costs | Higher initial tooling and equipment investment | Lower tooling cost; established stamping dies |

| Production Speed | Slower cycle times due to heating and gradual forming | Faster process with rapid stamping cycles |

| Applications | Used in aerospace, biomedical implants, and complex aerospace components | Applicable for automotive parts, simpler aerospace panels, and bulk production |

| Cost Efficiency | Cost-effective for low volume, high complexity parts | Cost-effective for high volume, simple parts |

Overview of Titanium Forming Technologies

Titanium forming technologies include SPF (Superplastic Forming) and traditional titanium stamping, each offering distinct advantages in manufacturing precision aerospace and automotive components. SPF allows complex shapes with uniform thickness and minimal residual stress by heating titanium to its superplastic state, whereas traditional stamping relies on mechanical deformation at lower temperatures, which may cause work hardening and dimensional variability. These forming methods significantly influence the material's mechanical properties, production efficiency, and final component performance in high-demand applications.

What is SPF Titanium Forming?

SPF (Super Plastic Forming) titanium forming is a manufacturing process that uses the superplasticity of titanium alloys at elevated temperatures to create complex shapes with minimal material thinning and high precision. Unlike traditional titanium stamping, which relies on mechanical force at room temperature, SPF forming allows for intricate geometries and reduced tooling costs while maintaining superior mechanical properties. This technique is widely used in aerospace and medical industries for producing lightweight, high-strength titanium components.

Understanding Traditional Titanium Stamping

Traditional titanium stamping involves shaping titanium sheets by applying high pressure through dies, effectively creating intricate metal forms with precision. This method often requires significant force and custom tooling to accommodate titanium's high strength and low ductility, which can lead to increased production time and tool wear. Understanding these limitations highlights why SPF titanium forming is gaining traction, as it offers improved forming capabilities with less material strain and enhanced design flexibility.

Material Properties: SPF vs Traditional Stamping

SPF Titanium forming enhances material properties by preserving the metal's grain structure, resulting in superior strength and fatigue resistance compared to traditional titanium stamping which can cause grain distortion and weaken the metal. The near-net shape capability of SPF allows for reduced material waste and improved dimensional accuracy, essential for aerospace and medical applications. SPF titanium also exhibits better corrosion resistance due to minimal heat input during forming, unlike traditional stamping that often involves higher temperatures causing microstructural changes.

Process Efficiency and Cycle Time Comparison

SPF Titanium forming significantly reduces cycle time compared to traditional titanium stamping by eliminating multiple intermediate machining steps, enabling faster production with less material waste. This process efficiency is achieved through near-net-shape manufacturing, which enhances dimensional accuracy and reduces secondary operations. Consequently, SPF Titanium forming offers superior cost-effectiveness and higher throughput for complex titanium components.

Design Flexibility in SPF vs Stamping

SPF Titanium forming offers superior design flexibility compared to traditional titanium stamping by enabling complex, lightweight geometries without the constraints of die shapes. This process allows for precise control of material thickness and fiber orientation, optimizing strength-to-weight ratios for aerospace and automotive applications. Unlike stamping, SPF reduces tooling costs and lead times, facilitating rapid prototyping and customized component production.

Cost Analysis: SPF Forming and Traditional Stamping

SPF titanium forming reduces material waste by up to 30% compared to traditional stamping, significantly lowering raw material costs. Traditional titanium stamping incurs higher tooling expenses due to complex die maintenance and shorter tool life, escalating overall production costs. SPF forming streamlines manufacturing with fewer operational steps, resulting in labor cost savings and faster production cycles.

Surface Finish and Quality Considerations

SPF Titanium forming offers superior surface finish quality compared to traditional titanium stamping, reducing the need for secondary machining processes and minimizing surface defects such as scratches or tooling marks. The SPF process enhances material integrity by maintaining consistent grain structure and thickness uniformity, which is critical for applications demanding high corrosion resistance and fatigue strength. Traditional stamping often results in variable surface textures and potential micro-cracks, impacting the overall durability and performance of titanium components.

Applications of SPF and Stamped Titanium Parts

SPF titanium forming enables the production of complex, lightweight aerospace components with enhanced structural integrity, making it ideal for aircraft engine parts, airframes, and defense applications. Traditional titanium stamping remains suited for high-volume automotive and consumer products requiring consistent, cost-effective shapes like brackets and fasteners. The superior strength-to-weight ratio and design flexibility of SPF titanium parts expand possibilities in advanced engineering fields compared to conventional stamped pieces.

Future Trends in Titanium Forming Technology

SPF titanium forming technology offers enhanced precision and reduced material waste compared to traditional titanium stamping, enabling the production of complex geometries with superior mechanical properties. Emerging trends in titanium forming emphasize additive manufacturing integration, advanced simulation techniques, and eco-friendly processes that optimize energy consumption and reduce environmental impact. The continued development of high-strength titanium alloys and hybrid forming methods is expected to drive innovations in aerospace, automotive, and medical industries.

SPF Titanium Forming vs Traditional Titanium Stamping Infographic

materialdif.com

materialdif.com