Sponge titanium offers higher purity and improved strength-to-weight ratio compared to ingot titanium, making it ideal for aerospace and medical applications. It undergoes complex processing to remove impurities, resulting in superior performance characteristics. Ingot titanium, while more cost-effective, typically contains more impurities and is better suited for less critical uses.

Table of Comparison

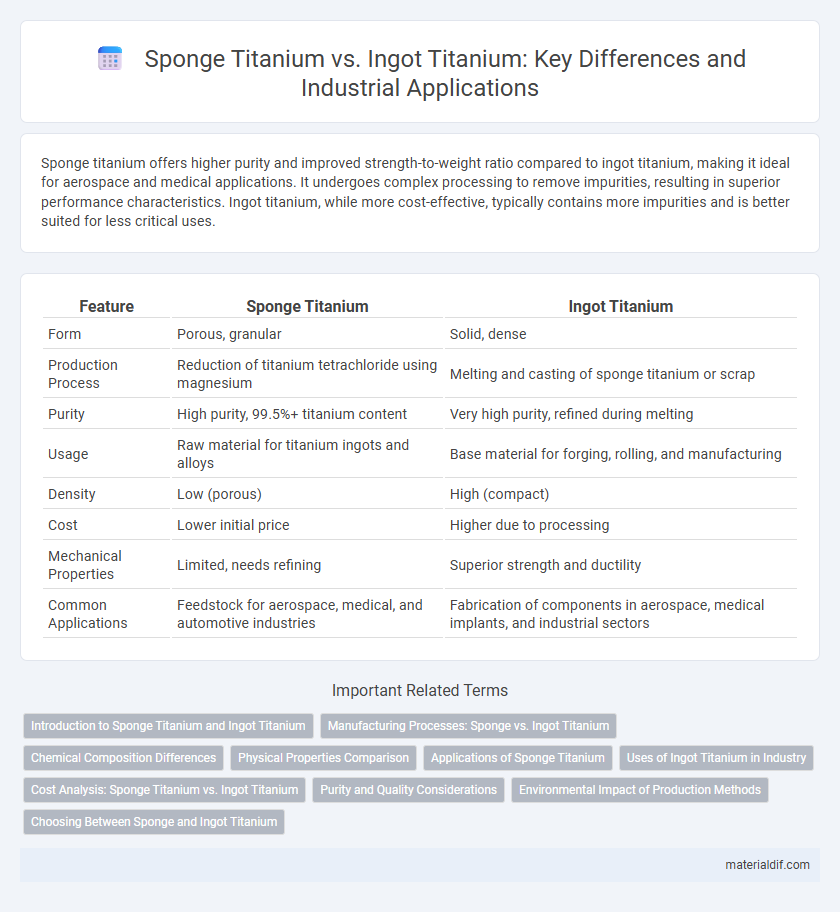

| Feature | Sponge Titanium | Ingot Titanium |

|---|---|---|

| Form | Porous, granular | Solid, dense |

| Production Process | Reduction of titanium tetrachloride using magnesium | Melting and casting of sponge titanium or scrap |

| Purity | High purity, 99.5%+ titanium content | Very high purity, refined during melting |

| Usage | Raw material for titanium ingots and alloys | Base material for forging, rolling, and manufacturing |

| Density | Low (porous) | High (compact) |

| Cost | Lower initial price | Higher due to processing |

| Mechanical Properties | Limited, needs refining | Superior strength and ductility |

| Common Applications | Feedstock for aerospace, medical, and automotive industries | Fabrication of components in aerospace, medical implants, and industrial sectors |

Introduction to Sponge Titanium and Ingot Titanium

Sponge titanium is a porous form produced through the Kroll process, characterized by its raw, brittle structure ideal for subsequent melting and refining stages. Ingot titanium is the purified, solid metal formed by melting sponge titanium into dense, homogenous blocks suitable for industrial applications. The contrast between the two lies in sponge titanium's intermediate, unrefined state versus ingot titanium's finished, machinable form used in aerospace and medical industries.

Manufacturing Processes: Sponge vs. Ingot Titanium

Sponge titanium is produced through the Kroll process, where titanium tetrachloride is reduced with magnesium, resulting in porous, sponge-like titanium that requires melting to form ingots. Ingot titanium is created by melting sponge titanium in a vacuum arc remelting furnace, which refines the metal into a dense, solid block suitable for further processing. The manufacturing process of sponge titanium focuses on chemical reduction, while ingot titanium emphasizes melting and solidification to achieve desired mechanical properties.

Chemical Composition Differences

Sponge titanium primarily consists of 99.5% pure titanium, with trace impurities such as oxygen, nitrogen, and hydrogen not exceeding specified limits, making it ideal as a raw material for further processing. Ingot titanium is produced by melting sponge titanium under controlled conditions, resulting in a more refined chemical composition with reduced interstitial elements and enhanced homogeneity. The key difference lies in ingot titanium's lower levels of contaminants and controlled alloying elements, which significantly improve mechanical properties and corrosion resistance.

Physical Properties Comparison

Sponge titanium features a porous, low-density structure with higher surface area, resulting in lower mechanical strength and increased reactivity compared to ingot titanium. In contrast, ingot titanium offers a dense, homogeneous microstructure providing superior tensile strength, hardness, and corrosion resistance. The physical differences influence their applications, with sponge primarily serving as a raw material for further processing into ingot or alloy forms.

Applications of Sponge Titanium

Sponge titanium serves as the primary raw material for producing high-grade titanium ingots used extensively in aerospace, medical implants, and chemical processing industries due to its superior purity and consistent quality. Its porous structure allows for efficient melting and alloying, resulting in strong, lightweight components crucial for aircraft frames and surgical devices. Unlike ingot titanium, sponge titanium's versatility and ease of processing make it ideal for manufacturing specialized titanium-based alloys tailored to specific performance requirements.

Uses of Ingot Titanium in Industry

Ingot titanium, characterized by its high density and refined grain structure, is widely used in aerospace engineering for manufacturing airframes and engine components due to its superior strength-to-weight ratio and corrosion resistance. It serves critical roles in chemical processing plants where its resistance to aggressive chemicals and high temperatures ensures durability and safety. The medical industry relies on ingot titanium for producing surgical implants and prosthetics because of its biocompatibility and mechanical properties.

Cost Analysis: Sponge Titanium vs. Ingot Titanium

Sponge titanium is significantly cheaper to produce than ingot titanium due to lower processing and raw material costs, with sponge titanium price fluctuating around $4-$6 per kilogram while ingot titanium typically ranges from $15-$30 per kilogram. The cost advantage of sponge titanium arises from its direct production via the Kroll process, bypassing the expensive melting and refining steps required for ingots. Despite the lower cost, ingot titanium offers superior purity and mechanical properties, justifying its higher price in aerospace and medical applications.

Purity and Quality Considerations

Sponge titanium exhibits higher purity levels due to its porous structure that allows for easier removal of impurities during initial processing, resulting in superior quality suitable for aerospace and medical applications. Ingot titanium, produced by melting sponge titanium, may contain minor inclusions or defects from the melting process, which can slightly affect the final material's purity and mechanical properties. Choosing between sponge and ingot titanium depends on the specific requirements for purity, strength, and application performance in critical industries.

Environmental Impact of Production Methods

Sponge titanium production requires more energy and emits higher levels of greenhouse gases due to the complex Kroll process, which involves extensive chemical reduction and high-temperature treatments. Ingot titanium, produced by melting sponge titanium through methods like vacuum arc remelting, has a relatively lower environmental footprint because it consolidates material with less additional processing. Choosing ingot titanium can reduce resource consumption and pollution compared to the initial sponge titanium stage, making it a more sustainable option in titanium manufacturing.

Choosing Between Sponge and Ingot Titanium

Sponge titanium offers a porous, lightweight structure ideal for chemical processing and aerospace applications requiring high purity and reactivity, while ingot titanium provides a dense, solid form suitable for metalworking and manufacturing durable components. Selecting between sponge and ingot titanium depends on the intended use, with sponge titanium preferred for further refining and alloying, and ingot titanium chosen for fabrication and machining. Understanding the difference in physical form and purity levels is essential for optimizing material performance in specific industrial processes.

Sponge Titanium vs Ingot Titanium Infographic

materialdif.com

materialdif.com