Sintered titanium offers superior porosity and enhanced mechanical properties compared to rolled titanium, making it ideal for lightweight, high-strength applications. The sintering process fuses titanium powder under heat and pressure, creating a material with excellent wear resistance and fatigue strength. Rolled titanium, while more uniform and less porous, is better suited for applications requiring high ductility and smooth surface finishes.

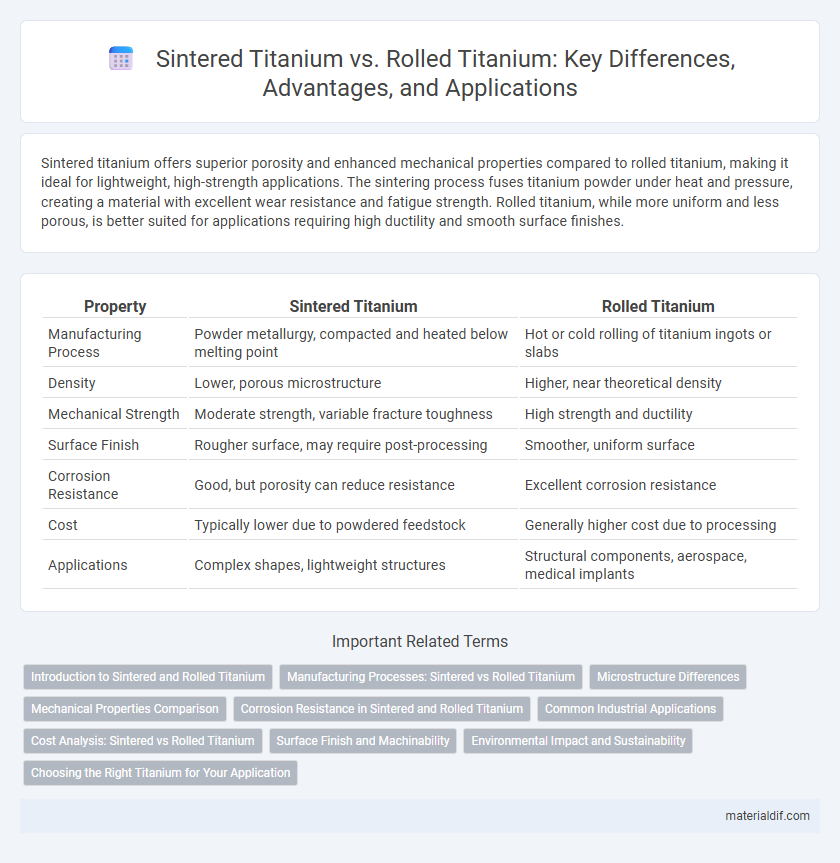

Table of Comparison

| Property | Sintered Titanium | Rolled Titanium |

|---|---|---|

| Manufacturing Process | Powder metallurgy, compacted and heated below melting point | Hot or cold rolling of titanium ingots or slabs |

| Density | Lower, porous microstructure | Higher, near theoretical density |

| Mechanical Strength | Moderate strength, variable fracture toughness | High strength and ductility |

| Surface Finish | Rougher surface, may require post-processing | Smoother, uniform surface |

| Corrosion Resistance | Good, but porosity can reduce resistance | Excellent corrosion resistance |

| Cost | Typically lower due to powdered feedstock | Generally higher cost due to processing |

| Applications | Complex shapes, lightweight structures | Structural components, aerospace, medical implants |

Introduction to Sintered and Rolled Titanium

Sintered titanium is produced by compacting titanium powder under high pressure and temperature, resulting in a porous structure with enhanced strength-to-weight ratio and superior wear resistance. Rolled titanium is manufactured by passing titanium slabs through rollers at high temperatures, creating dense, uniform sheets characterized by excellent ductility, toughness, and corrosion resistance. Both processes influence the microstructure and mechanical properties, making sintered titanium ideal for lightweight aerospace components and rolled titanium suitable for structural applications requiring high strength and flexibility.

Manufacturing Processes: Sintered vs Rolled Titanium

Sintered titanium is produced through powder metallurgy, where titanium powder is compacted and heated below its melting point to form a solid mass with a porous microstructure. Rolled titanium involves mechanical deformation by passing titanium slabs or billets through rollers, resulting in a dense, homogeneous material with improved strength and ductility. The sintering process allows for near-net shape manufacturing with controlled porosity, while rolling enables enhanced mechanical properties and surface finish through grain refinement.

Microstructure Differences

Sintered titanium exhibits a porous microstructure with interconnected particles formed through powder metallurgy, enhancing surface area and promoting osseointegration in biomedical applications. Rolled titanium features a dense, elongated grain structure due to plastic deformation during rolling, resulting in improved mechanical strength and fatigue resistance. The microstructural distinctions between sintered and rolled titanium directly influence their mechanical properties and suitability for different industrial uses.

Mechanical Properties Comparison

Sintered titanium exhibits lower tensile strength and reduced ductility compared to rolled titanium due to its porous microstructure, which affects load distribution and fracture resistance. Rolled titanium demonstrates superior mechanical properties such as higher yield strength, improved fatigue resistance, and enhanced toughness attributed to its refined grain structure and directional grain flow. These distinctions make rolled titanium more suitable for critical structural applications requiring enhanced mechanical performance.

Corrosion Resistance in Sintered and Rolled Titanium

Sintered titanium exhibits superior corrosion resistance due to its refined microstructure and reduced porosity, which minimizes pathways for corrosive agents. Rolled titanium also offers excellent corrosion resistance but may have slightly higher susceptibility to localized corrosion in aggressive environments because of its elongated grain structure. Both forms provide robust protection in marine and chemical applications, yet sintered titanium's uniform microstructure enhances its durability against corrosion over extended periods.

Common Industrial Applications

Sintered titanium is commonly used in aerospace components, biomedical implants, and high-performance filtration systems due to its excellent porosity and strength-to-weight ratio. Rolled titanium finds widespread application in aerospace airframes, automotive parts, and chemical processing equipment because of its superior mechanical strength and improved surface finish. Both materials serve crucial roles in industries demanding lightweight durability and corrosion resistance.

Cost Analysis: Sintered vs Rolled Titanium

Sintered titanium generally incurs higher production costs due to complex powder metallurgy processes and longer manufacturing cycles compared to rolled titanium, which benefits from more streamlined and widely established rolling techniques. Rolled titanium offers better cost efficiency for large-scale production with consistent mechanical properties, while sintered titanium enables complex geometries and superior material utilization but at premium pricing. In cost analysis, rolled titanium remains the preferred choice for applications prioritizing budget and volume, whereas sintered titanium is selected when design complexity and material performance justify the increased expense.

Surface Finish and Machinability

Sintered titanium offers a porous surface finish ideal for biomedical implants requiring bone integration, while rolled titanium provides a smooth, dense surface suited for aerospace and structural applications. Rolled titanium exhibits superior machinability with consistent mechanical properties and easier precision shaping, whereas sintered titanium's brittleness and porosity make machining more challenging and limit its use to specialized roles. Surface finish and machinability differences between sintered and rolled titanium directly impact their suitability for various high-performance engineering applications.

Environmental Impact and Sustainability

Sintered titanium typically requires less energy during production compared to rolled titanium, reducing overall carbon emissions and making it more environmentally sustainable. The sintering process minimizes material waste by precisely shaping titanium powder, whereas rolled titanium involves significant material deformation and scrap generation. Consequently, sintered titanium presents a greener alternative with improved resource efficiency and a lower ecological footprint.

Choosing the Right Titanium for Your Application

Sintered titanium offers superior porosity and enhanced mechanical properties ideal for biomedical implants requiring bone integration, while rolled titanium provides higher strength and excellent surface finish suitable for aerospace and industrial applications. Understanding the differences in microstructure and fabrication methods helps in selecting the optimal titanium type based on load-bearing requirements and corrosion resistance. Evaluating factors such as grain size, density, and cost-effectiveness ensures the right titanium variant aligns with specific performance criteria in engineering projects.

Sintered Titanium vs Rolled Titanium Infographic

materialdif.com

materialdif.com