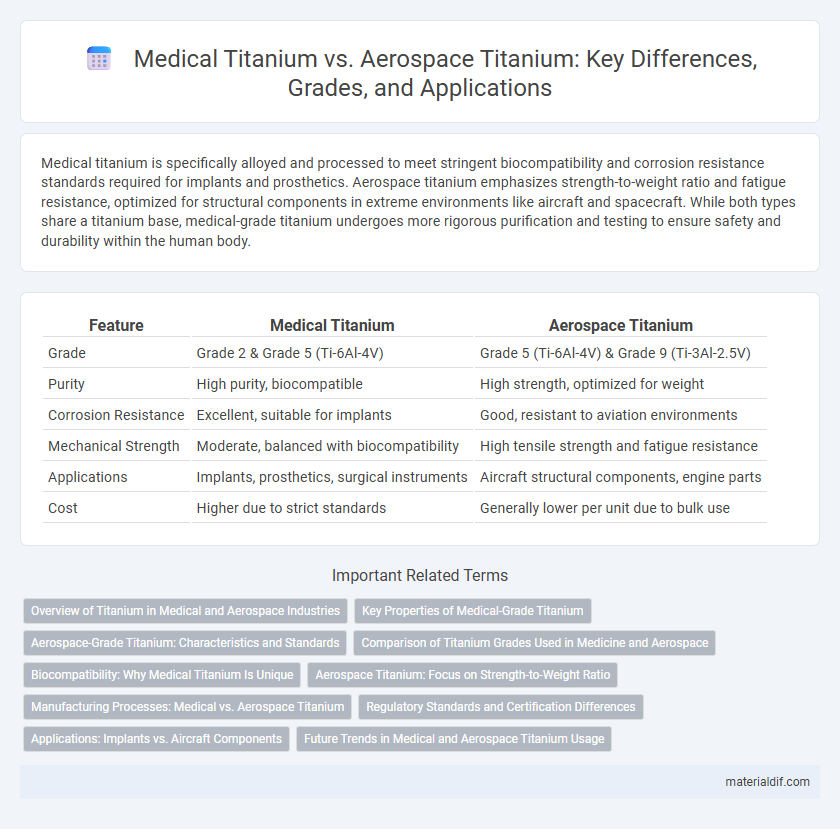

Medical titanium is specifically alloyed and processed to meet stringent biocompatibility and corrosion resistance standards required for implants and prosthetics. Aerospace titanium emphasizes strength-to-weight ratio and fatigue resistance, optimized for structural components in extreme environments like aircraft and spacecraft. While both types share a titanium base, medical-grade titanium undergoes more rigorous purification and testing to ensure safety and durability within the human body.

Table of Comparison

| Feature | Medical Titanium | Aerospace Titanium |

|---|---|---|

| Grade | Grade 2 & Grade 5 (Ti-6Al-4V) | Grade 5 (Ti-6Al-4V) & Grade 9 (Ti-3Al-2.5V) |

| Purity | High purity, biocompatible | High strength, optimized for weight |

| Corrosion Resistance | Excellent, suitable for implants | Good, resistant to aviation environments |

| Mechanical Strength | Moderate, balanced with biocompatibility | High tensile strength and fatigue resistance |

| Applications | Implants, prosthetics, surgical instruments | Aircraft structural components, engine parts |

| Cost | Higher due to strict standards | Generally lower per unit due to bulk use |

Overview of Titanium in Medical and Aerospace Industries

Titanium's exceptional strength-to-weight ratio and corrosion resistance make it indispensable in both medical and aerospace industries. In medical applications, titanium is favored for implants and prosthetics due to its biocompatibility and ability to integrate with bone tissue. Aerospace utilizes titanium alloys for structural components and engine parts, benefiting from its high fatigue resistance and stability under extreme temperatures.

Key Properties of Medical-Grade Titanium

Medical-grade titanium exhibits exceptional biocompatibility, corrosion resistance, and strength, making it ideal for implants and prosthetics. Its ability to osseointegrate with bone tissue ensures long-term stability in medical applications. Aerospace titanium, while also strong and corrosion-resistant, prioritizes lightweight and high-temperature performance over biocompatibility.

Aerospace-Grade Titanium: Characteristics and Standards

Aerospace-grade titanium is distinguished by its high strength-to-weight ratio, exceptional corrosion resistance, and ability to withstand extreme temperatures, making it ideal for critical aircraft components. Commonly used alloys like Ti-6Al-4V meet stringent industry standards such as AMS 4928 and ASTM B265, ensuring superior mechanical properties and reliability. These standards govern chemical composition, tensile strength, and fatigue resistance, enabling aerospace titanium to deliver optimal performance under demanding flight conditions.

Comparison of Titanium Grades Used in Medicine and Aerospace

Medical titanium typically employs Grades 1, 2, 4, and Ti-6Al-4V ELI alloy, favored for biocompatibility, corrosion resistance, and strength suitable for implants. Aerospace titanium primarily uses Grade 5 (Ti-6Al-4V) and other high-strength alloys due to their superior strength-to-weight ratio and excellent fatigue resistance under extreme conditions. The key difference lies in purity and alloying elements, with medical grades prioritizing biocompatibility and aerospace grades optimizing mechanical performance.

Biocompatibility: Why Medical Titanium Is Unique

Medical titanium is uniquely biocompatible due to its exceptional corrosion resistance and ability to integrate with human bone through osseointegration, making it ideal for implants and prosthetics. Aerospace titanium, while strong and lightweight, lacks the same surface treatments and purity levels required for compatibility with biological tissues. The specialized grade 5 and grade 23 titanium alloys used in medical applications ensure minimal immune response and long-term durability inside the human body.

Aerospace Titanium: Focus on Strength-to-Weight Ratio

Aerospace titanium alloys exhibit a superior strength-to-weight ratio, making them ideal for aircraft and spacecraft components where weight reduction is critical without compromising structural integrity. These titanium grades, such as Ti-6Al-4V, offer exceptional corrosion resistance, high fatigue strength, and the ability to withstand extreme temperatures, outperforming medical titanium variants optimized primarily for biocompatibility. The enhanced mechanical properties of aerospace titanium enable the design of lighter, more fuel-efficient airframes and engines, driving innovation in aerospace engineering.

Manufacturing Processes: Medical vs. Aerospace Titanium

Medical titanium undergoes precision manufacturing processes such as cold forging, electro-polishing, and stringent biocompatibility testing to ensure implant safety and corrosion resistance. Aerospace titanium is manufactured through advanced techniques like vacuum arc remelting, hot isostatic pressing, and additive manufacturing to achieve high strength-to-weight ratios and fatigue resistance under extreme conditions. Both sectors prioritize specific heat treatments and surface modifications tailored to their respective performance and durability standards.

Regulatory Standards and Certification Differences

Medical titanium must comply with strict biocompatibility standards such as ASTM F67 and ISO 10993 to ensure safety and efficacy in implants, while aerospace titanium adheres to standards like AMS 4911 and AMS 4777 for mechanical performance and fatigue resistance. Certification for medical titanium involves rigorous testing for corrosion resistance and toxicity to meet FDA or CE requirements, contrasting with aerospace certifications focused on tensile strength, fracture toughness, and material traceability under AS9100 standards. Regulatory frameworks emphasize patient safety and implant longevity in medical titanium, whereas aerospace titanium certification prioritizes structural integrity and performance under extreme environmental conditions.

Applications: Implants vs. Aircraft Components

Medical titanium is specifically engineered for biocompatibility, corrosion resistance, and strength, making it ideal for implants such as joint replacements and dental devices that require longevity inside the human body. Aerospace titanium, on the other hand, emphasizes high strength-to-weight ratio, heat resistance, and fatigue durability, essential for aircraft components like airframes, engine parts, and fasteners exposed to extreme conditions. Both forms exploit titanium's unique properties, but medical titanium prioritizes biological safety while aerospace titanium focuses on mechanical performance and environmental endurance.

Future Trends in Medical and Aerospace Titanium Usage

Future trends in medical and aerospace titanium usage are driven by advancements in alloy development and additive manufacturing technologies, enabling the production of lighter, stronger, and more corrosion-resistant materials. In medical applications, titanium alloys with enhanced biocompatibility and improved osseointegration properties are prioritized for implants and prosthetics. Aerospace titanium advancements focus on increasing fatigue resistance and thermal stability to meet the demands of next-generation aircraft and spacecraft designs.

Medical Titanium vs Aerospace Titanium Infographic

materialdif.com

materialdif.com