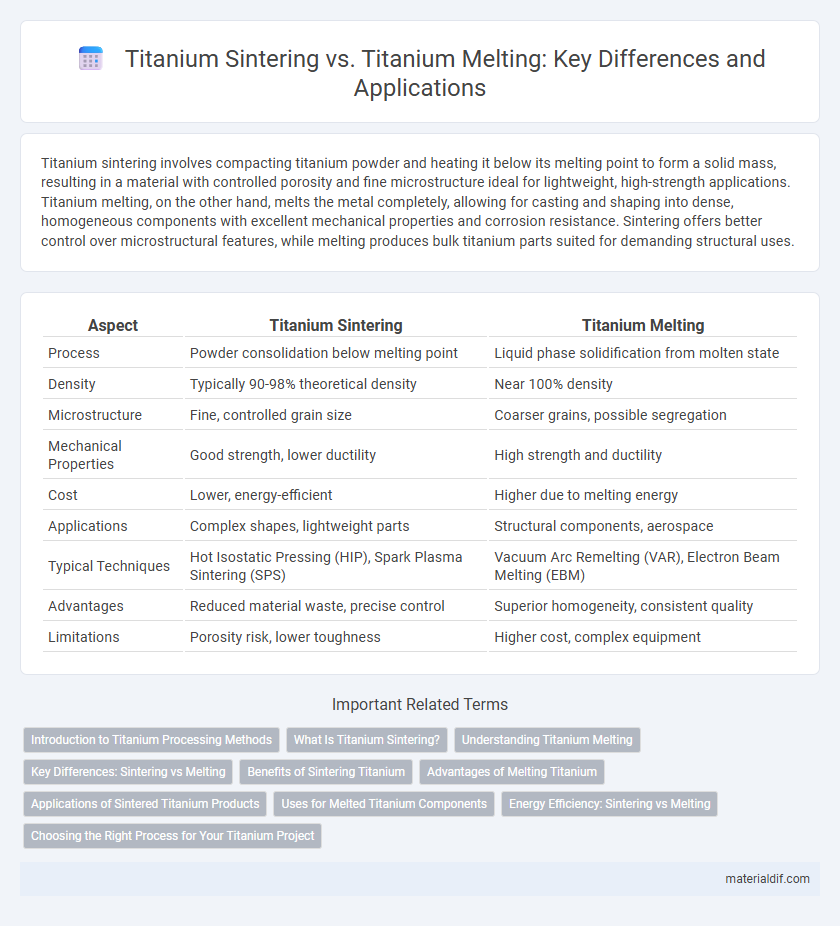

Titanium sintering involves compacting titanium powder and heating it below its melting point to form a solid mass, resulting in a material with controlled porosity and fine microstructure ideal for lightweight, high-strength applications. Titanium melting, on the other hand, melts the metal completely, allowing for casting and shaping into dense, homogeneous components with excellent mechanical properties and corrosion resistance. Sintering offers better control over microstructural features, while melting produces bulk titanium parts suited for demanding structural uses.

Table of Comparison

| Aspect | Titanium Sintering | Titanium Melting |

|---|---|---|

| Process | Powder consolidation below melting point | Liquid phase solidification from molten state |

| Density | Typically 90-98% theoretical density | Near 100% density |

| Microstructure | Fine, controlled grain size | Coarser grains, possible segregation |

| Mechanical Properties | Good strength, lower ductility | High strength and ductility |

| Cost | Lower, energy-efficient | Higher due to melting energy |

| Applications | Complex shapes, lightweight parts | Structural components, aerospace |

| Typical Techniques | Hot Isostatic Pressing (HIP), Spark Plasma Sintering (SPS) | Vacuum Arc Remelting (VAR), Electron Beam Melting (EBM) |

| Advantages | Reduced material waste, precise control | Superior homogeneity, consistent quality |

| Limitations | Porosity risk, lower toughness | Higher cost, complex equipment |

Introduction to Titanium Processing Methods

Titanium processing methods primarily include sintering and melting, each offering distinct advantages for manufacturing. Titanium sintering involves compacting and heating titanium powders below the melting point, producing parts with fine microstructures and controlled porosity ideal for additive manufacturing and complex geometries. Titanium melting, typically performed through vacuum arc remelting or electron beam melting, achieves full densification with superior mechanical properties, making it suitable for aerospace and biomedical components requiring high strength and corrosion resistance.

What Is Titanium Sintering?

Titanium sintering is a powder metallurgy process where titanium powder particles are heated below their melting point until they bond together, forming a solid, porous structure. Unlike titanium melting, which involves fully liquefying the metal, sintering preserves the fine microstructure and offers superior control over porosity and part density. This method is commonly used to create complex shapes with reduced material waste and improved mechanical properties in aerospace and medical implant applications.

Understanding Titanium Melting

Titanium melting involves heating titanium above its melting point of 1,668degC (3,034degF), allowing it to transition from a solid to a liquid state for processes such as casting and alloying. This process ensures uniform composition and density, essential for applications demanding high strength-to-weight ratios and corrosion resistance, such as aerospace and medical implants. Unlike sintering, which compacts titanium powder below melting temperature, melting produces fully dense titanium with superior mechanical properties and fewer microstructural defects.

Key Differences: Sintering vs Melting

Titanium sintering involves heating titanium powder below its melting point to bond particles through diffusion, preserving microstructural properties and reducing distortion, while titanium melting melts the metal entirely, allowing reshaping but risking grain growth and oxidation. Sintering offers superior control over porosity and composition uniformity, whereas melting enables full densification and complex shape formation. The choice between sintering and melting depends on required mechanical properties, part complexity, and cost considerations.

Benefits of Sintering Titanium

Titanium sintering offers improved control over microstructure, resulting in enhanced mechanical properties such as increased strength and fatigue resistance compared to melting. This process reduces oxidation and contamination risks by operating below melting temperatures, preserving titanium's purity and performance. Sintering also enables near-net-shape manufacturing, minimizing material waste and machining costs, which is critical for aerospace and biomedical applications.

Advantages of Melting Titanium

Titanium melting offers superior alloy homogeneity and precise control over chemical composition compared to sintering, resulting in enhanced mechanical properties and corrosion resistance. Melting processes such as vacuum arc remelting (VAR) and electron beam melting (EBM) reduce porosity and impurities, which significantly improve the structural integrity of the titanium components. The ability to produce complex shapes and fully dense parts through melting techniques makes it preferable for high-performance aerospace and biomedical applications.

Applications of Sintered Titanium Products

Sintered titanium products are widely used in aerospace, automotive, and medical industries due to their excellent strength-to-weight ratio and precise control over porosity. The sintering process allows for the production of complex shapes and tailored microstructures that enhance wear resistance and fatigue performance in aerospace components and medical implants. Porous sintered titanium is particularly valued for biomedical applications such as bone scaffolds and dental implants, where osseointegration and biocompatibility are critical.

Uses for Melted Titanium Components

Melted titanium components are widely used in aerospace, medical implants, and automotive industries due to their superior material homogeneity and mechanical properties compared to sintered parts. Titanium melting processes, such as vacuum arc remelting (VAR) and electron beam melting (EBM), produce dense, high-strength components ideal for critical load-bearing applications and complex geometries. These melted titanium parts offer enhanced corrosion resistance and fatigue performance, making them suitable for high-demand environments where reliability and durability are essential.

Energy Efficiency: Sintering vs Melting

Titanium sintering consumes significantly less energy compared to melting due to its lower processing temperature, typically below 1300degC versus melting points above 1600degC. Sintering optimizes powder particle bonding through diffusion without fully liquefying the metal, resulting in reduced thermal input and shorter cycle times. These energy savings make sintering a more sustainable choice for manufacturing titanium components while maintaining mechanical integrity.

Choosing the Right Process for Your Titanium Project

Titanium sintering offers precise control over microstructure and reduced material waste, making it ideal for complex, high-performance components with tight tolerances. Titanium melting, such as vacuum arc remelting, produces fully dense ingots suitable for large-scale structural parts requiring superior mechanical strength and homogeneity. Selecting between sintering and melting depends on project requirements like part complexity, mechanical properties, production volume, and cost constraints to optimize performance and efficiency.

Titanium Sintering vs Titanium Melting Infographic

materialdif.com

materialdif.com