Titanium tubing outperforms aluminum tubing in strength-to-weight ratio, providing exceptional durability without adding extra weight, making it ideal for high-performance applications. Its superior corrosion resistance ensures longevity even in harsh environments, whereas aluminum tubing is more prone to oxidation and fatigue over time. Titanium's flexibility and resistance to deformation under stress offer enhanced reliability compared to the more rigid and brittle nature of aluminum tubing.

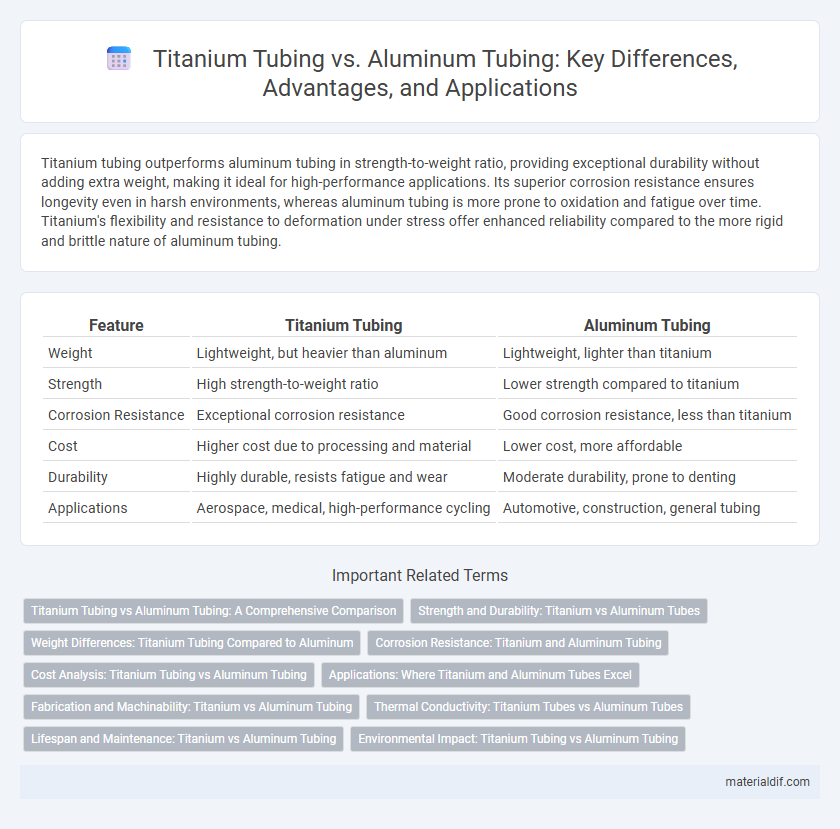

Table of Comparison

| Feature | Titanium Tubing | Aluminum Tubing |

|---|---|---|

| Weight | Lightweight, but heavier than aluminum | Lightweight, lighter than titanium |

| Strength | High strength-to-weight ratio | Lower strength compared to titanium |

| Corrosion Resistance | Exceptional corrosion resistance | Good corrosion resistance, less than titanium |

| Cost | Higher cost due to processing and material | Lower cost, more affordable |

| Durability | Highly durable, resists fatigue and wear | Moderate durability, prone to denting |

| Applications | Aerospace, medical, high-performance cycling | Automotive, construction, general tubing |

Titanium Tubing vs Aluminum Tubing: A Comprehensive Comparison

Titanium tubing offers superior strength-to-weight ratio and corrosion resistance compared to aluminum tubing, making it ideal for aerospace and medical applications where durability and biocompatibility are critical. Despite aluminum tubing being more cost-effective and easier to machine, titanium's higher fatigue resistance and ability to withstand extreme temperatures provide unmatched performance in demanding environments. The choice between titanium and aluminum tubing ultimately depends on balancing budget constraints with the need for exceptional mechanical properties and longevity.

Strength and Durability: Titanium vs Aluminum Tubes

Titanium tubing offers superior strength-to-weight ratio compared to aluminum, making it ideal for high-performance applications requiring durable yet lightweight materials. Its exceptional corrosion resistance and fatigue endurance ensure longer service life in harsh environments, outperforming aluminum tubes prone to oxidation and structural degradation. Although aluminum tubing is lighter and less expensive, titanium's robustness and durability often justify the higher cost in demanding engineering projects.

Weight Differences: Titanium Tubing Compared to Aluminum

Titanium tubing offers a superior strength-to-weight ratio compared to aluminum, resulting in a material that is typically 30-40% heavier than aluminum but significantly stronger and more durable. Although aluminum tubing is lighter, titanium's enhanced tensile strength allows for thinner walls and less material usage, partially offsetting the weight difference in structural applications. This makes titanium tubing particularly advantageous in aerospace and high-performance industries where weight savings and material strength are critical factors.

Corrosion Resistance: Titanium and Aluminum Tubing

Titanium tubing offers superior corrosion resistance compared to aluminum tubing, especially in harsh environments such as saltwater and industrial atmospheres. The dense oxide layer on titanium surfaces provides exceptional protection against oxidation and chemical attack, extending the lifespan of components significantly. In contrast, aluminum tubing is more susceptible to corrosion, particularly pitting and galvanic corrosion, limiting its durability in aggressive conditions.

Cost Analysis: Titanium Tubing vs Aluminum Tubing

Titanium tubing typically costs three to five times more than aluminum tubing due to its higher raw material and processing expenses. While titanium offers superior strength-to-weight ratio and corrosion resistance, these benefits come at a premium price, especially for large-scale applications. Aluminum tubing remains the more cost-effective option for projects with budget constraints and less demanding performance requirements.

Applications: Where Titanium and Aluminum Tubes Excel

Titanium tubing excels in aerospace, medical devices, and chemical processing due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Aluminum tubing is preferred in automotive, construction, and heat exchanger applications for its lightweight nature, excellent thermal conductivity, and cost-effectiveness. The choice between titanium and aluminum tubes depends on the specific demands of the application, including mechanical properties, environmental exposure, and budget constraints.

Fabrication and Machinability: Titanium vs Aluminum Tubing

Titanium tubing offers superior strength-to-weight ratio and corrosion resistance but presents greater challenges in fabrication due to its hardness and reactivity at high temperatures, requiring specialized tools and techniques. Aluminum tubing, while easier to machine and form with standard equipment, lacks the same mechanical strength and fatigue resistance as titanium. Choosing between titanium and aluminum tubing depends on balancing fabrication complexity against performance requirements in aerospace, medical, and industrial applications.

Thermal Conductivity: Titanium Tubes vs Aluminum Tubes

Titanium tubing has significantly lower thermal conductivity, approximately 7 W/m*K, compared to aluminum tubing, which ranges from 205 to 240 W/m*K. This makes titanium tubes ideal for applications requiring heat resistance and insulation, while aluminum tubes are preferred for heat dissipation and efficient thermal transfer. The choice between titanium and aluminum tubing depends on specific requirements for thermal management in industries like aerospace, automotive, and heat exchangers.

Lifespan and Maintenance: Titanium vs Aluminum Tubing

Titanium tubing offers superior lifespan compared to aluminum tubing due to its exceptional corrosion resistance and high strength-to-weight ratio, enabling it to withstand harsh environmental conditions without degrading. Maintenance requirements for titanium tubing are minimal, as its oxide layer naturally protects against rust and wear, reducing the need for frequent inspections and repairs. In contrast, aluminum tubing is more susceptible to corrosion and fatigue, necessitating regular maintenance to ensure longevity and structural integrity.

Environmental Impact: Titanium Tubing vs Aluminum Tubing

Titanium tubing has a significantly lower environmental impact compared to aluminum tubing due to its superior corrosion resistance and longer lifespan, reducing the need for frequent replacements and waste. The production of titanium, although energy-intensive, generates fewer greenhouse gas emissions per unit of strength than aluminum extraction and refining processes. Recycling titanium is more efficient and retains more material quality, contributing to a smaller ecological footprint over the product lifecycle.

Titanium Tubing vs Aluminum Tubing Infographic

materialdif.com

materialdif.com