Forged titanium offers superior strength and durability compared to cast titanium due to its denser molecular structure achieved through high-pressure forging processes. Cast titanium, while easier and less costly to produce, tends to have more internal voids and is generally less resistant to impact and fatigue. For pet accessories requiring long-lasting performance and enhanced safety, forged titanium is the preferred choice.

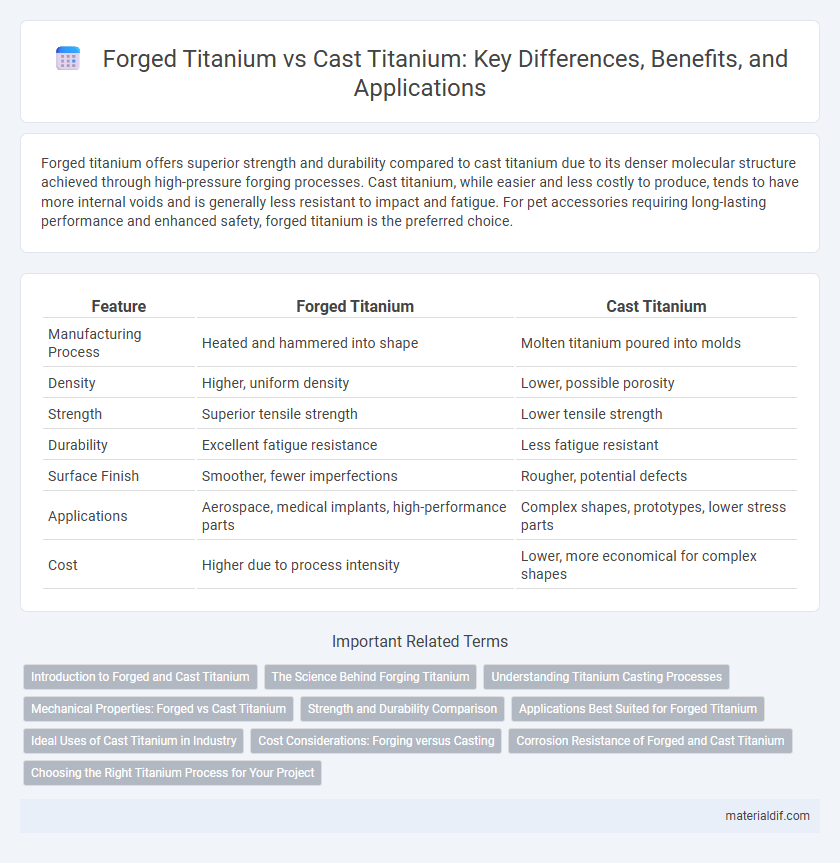

Table of Comparison

| Feature | Forged Titanium | Cast Titanium |

|---|---|---|

| Manufacturing Process | Heated and hammered into shape | Molten titanium poured into molds |

| Density | Higher, uniform density | Lower, possible porosity |

| Strength | Superior tensile strength | Lower tensile strength |

| Durability | Excellent fatigue resistance | Less fatigue resistant |

| Surface Finish | Smoother, fewer imperfections | Rougher, potential defects |

| Applications | Aerospace, medical implants, high-performance parts | Complex shapes, prototypes, lower stress parts |

| Cost | Higher due to process intensity | Lower, more economical for complex shapes |

Introduction to Forged and Cast Titanium

Forged titanium is produced by shaping heated titanium under high pressure, resulting in a denser structure with enhanced strength and fatigue resistance. Cast titanium is created by pouring molten titanium into molds, allowing for complex shapes but often with slightly reduced mechanical properties compared to forging. Both processes are essential in aerospace, medical, and automotive industries where titanium's corrosion resistance and high strength-to-weight ratio are critical.

The Science Behind Forging Titanium

Forged titanium undergoes a controlled deformation process that refines its grain structure, enhancing strength and fatigue resistance compared to cast titanium, which solidifies from molten metal and often contains internal porosity. The forging process aligns the titanium's crystalline grains, improving mechanical properties such as tensile strength and fracture toughness. These microstructural changes result in superior durability and performance in aerospace and medical applications where reliability is critical.

Understanding Titanium Casting Processes

Forged titanium involves shaping metal through compressive forces, enhancing grain structure and mechanical properties for superior strength and durability. Cast titanium, created by pouring molten metal into a mold, allows complex shapes but may have porosity and lower mechanical integrity compared to forged parts. Understanding differences in grain flow and defect formation is crucial for selecting the appropriate titanium casting process in aerospace and medical applications.

Mechanical Properties: Forged vs Cast Titanium

Forged titanium exhibits superior mechanical properties compared to cast titanium, including higher tensile strength, improved fatigue resistance, and enhanced toughness due to its refined grain structure formed under controlled deformation. Cast titanium often contains microstructural defects like porosity and inclusions, which can compromise its mechanical integrity and reduce fatigue life. These differences make forged titanium preferable for high-performance aerospace and biomedical applications where reliability and strength are critical.

Strength and Durability Comparison

Forged titanium exhibits superior strength and durability compared to cast titanium due to its denser microstructure formed under high pressure, which reduces porosity and enhances mechanical properties. Cast titanium, while easier to produce complex shapes, tends to have microstructural inconsistencies that can lead to lower strength and increased susceptibility to fatigue and cracking. These differences make forged titanium the preferred material in aerospace and medical implant applications where maximum performance and reliability are critical.

Applications Best Suited for Forged Titanium

Forged titanium is ideal for aerospace components, medical implants, and high-performance automotive parts due to its superior strength, toughness, and fatigue resistance compared to cast titanium. The forging process aligns the metal's grain structure, enhancing mechanical properties critical for safety and durability in demanding environments. Industries requiring lightweight yet strong materials, such as aviation and biomedical sectors, predominantly prefer forged titanium for critical load-bearing applications.

Ideal Uses of Cast Titanium in Industry

Cast titanium excels in complex geometries and intricate designs, making it ideal for aerospace engine components, medical implants, and chemical processing equipment. Its superior corrosion resistance and ability to withstand high temperatures suit harsh industrial environments. Industries benefit from cast titanium's precise molding capabilities for custom, high-strength parts where weight reduction is critical.

Cost Considerations: Forging versus Casting

Forged titanium generally incurs higher manufacturing costs than cast titanium due to the intensive labor, specialized equipment, and greater material waste involved in the forging process. Cast titanium offers more cost efficiency by allowing near-net shape production, reducing machining time and raw material consumption. Cost considerations often balance durability and strength benefits of forged titanium against the affordability and design flexibility provided by cast titanium.

Corrosion Resistance of Forged and Cast Titanium

Forged titanium exhibits superior corrosion resistance compared to cast titanium due to its denser and more uniform microstructure, which reduces susceptibility to pitting and crevice corrosion. The forging process minimizes internal defects and grain boundaries, enhancing the material's ability to withstand harsh environments such as seawater and chemical exposure. Cast titanium, while still corrosion-resistant, often contains microstructural inconsistencies that can lead to localized corrosion under aggressive conditions.

Choosing the Right Titanium Process for Your Project

Forged titanium boasts superior strength and durability due to its refined grain structure, making it ideal for high-stress applications such as aerospace components and medical implants. Cast titanium offers more complex shapes and design flexibility, suitable for projects requiring intricate geometries and lower volume production. Evaluating project requirements for mechanical performance, precision, and cost will guide the choice between forged and cast titanium processes.

Forged Titanium vs Cast Titanium Infographic

materialdif.com

materialdif.com