3D printed titanium offers enhanced design flexibility and complex geometries that milled titanium cannot easily achieve, making it ideal for customized and intricate pet products. The additive manufacturing process of 3D printing minimizes material waste compared to subtractive milling, which cuts away excess metal from a solid block. While milled titanium provides excellent surface finish and consistency, 3D printed titanium enables innovative shapes and lightweight structures without compromising strength or durability.

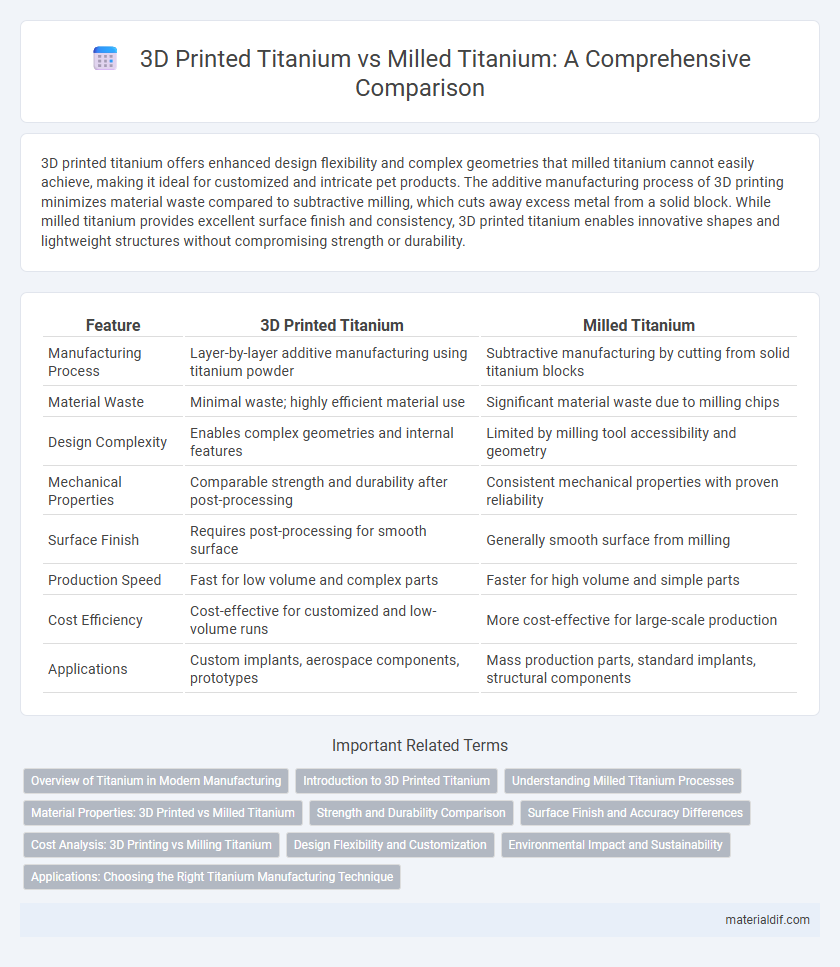

Table of Comparison

| Feature | 3D Printed Titanium | Milled Titanium |

|---|---|---|

| Manufacturing Process | Layer-by-layer additive manufacturing using titanium powder | Subtractive manufacturing by cutting from solid titanium blocks |

| Material Waste | Minimal waste; highly efficient material use | Significant material waste due to milling chips |

| Design Complexity | Enables complex geometries and internal features | Limited by milling tool accessibility and geometry |

| Mechanical Properties | Comparable strength and durability after post-processing | Consistent mechanical properties with proven reliability |

| Surface Finish | Requires post-processing for smooth surface | Generally smooth surface from milling |

| Production Speed | Fast for low volume and complex parts | Faster for high volume and simple parts |

| Cost Efficiency | Cost-effective for customized and low-volume runs | More cost-effective for large-scale production |

| Applications | Custom implants, aerospace components, prototypes | Mass production parts, standard implants, structural components |

Overview of Titanium in Modern Manufacturing

3D printed titanium offers enhanced design flexibility and complex geometries unattainable through traditional milling, making it ideal for aerospace, medical implants, and automotive components. Milled titanium, though limited to subtractive processes, ensures high precision, superior surface finish, and material integrity for critical applications requiring stringent tolerances. Both methods leverage titanium's exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, driving innovation in modern manufacturing industries.

Introduction to 3D Printed Titanium

3D printed titanium is revolutionizing the manufacturing industry by enabling the production of complex geometries with high precision and reduced material waste compared to traditional milled titanium. This additive manufacturing process builds parts layer-by-layer, allowing for lightweight, customized designs often used in aerospace, medical implants, and automotive components. Unlike milled titanium, which involves subtractive machining from a solid block, 3D printed titanium offers enhanced design flexibility and cost efficiency for low-volume and intricate parts.

Understanding Milled Titanium Processes

Milled titanium involves subtractive manufacturing where a solid titanium block is precisely shaped using computer-controlled cutting tools, offering superior surface finish and dimensional accuracy. This process allows for tight tolerances and complex geometries while ensuring the inherent strength and biocompatibility of titanium remain intact. Milled titanium is commonly used in aerospace and medical implants due to its consistent mechanical properties and reliable quality control.

Material Properties: 3D Printed vs Milled Titanium

3D printed titanium exhibits a unique microstructure characterized by fine grain sizes and directional properties due to rapid solidification during the additive manufacturing process. In contrast, milled titanium maintains a more uniform and isotropic grain structure resulting from traditional ingot casting and machining, enhancing its ductility and fatigue resistance. Both methods produce high-strength titanium, but 3D printed titanium offers superior design flexibility and potential for complex geometries without sacrificing material integrity.

Strength and Durability Comparison

3D printed titanium offers enhanced strength due to its layer-by-layer additive manufacturing process, which allows for complex geometries and controlled microstructures that improve load distribution. Milled titanium, though traditionally known for its uniform material density and consistent mechanical properties, may exhibit microstructural weaknesses caused by machining stresses. Durability in 3D printed titanium benefits from its potential for tailored design optimization, whereas milled titanium generally provides reliable fatigue resistance due to its homogeneous composition.

Surface Finish and Accuracy Differences

3D printed titanium offers complex geometries with layer-by-layer precision, but typically shows a rougher surface finish compared to milled titanium, which delivers smoother, high-quality surfaces due to subtractive manufacturing. Milling titanium achieves tighter dimensional tolerances and superior accuracy, essential for aerospace and medical applications where precision is critical. Surface finishing processes like polishing or bead blasting are often required to improve the print roughness of 3D printed titanium parts for functional and aesthetic purposes.

Cost Analysis: 3D Printing vs Milling Titanium

3D printed titanium offers significant cost savings in low-volume production due to reduced material waste and faster prototyping compared to traditional milled titanium, which incurs higher expenses from subtractive manufacturing processes and tool wear. The additive manufacturing approach minimizes raw material loss, making it economically advantageous for complex geometries and custom designs, while milling titanium requires extensive machining time and costly tooling maintenance. For high-volume production, milling can become more cost-effective as economies of scale reduce per-unit expenses, but 3D printing remains superior for lightweight, intricate parts where material efficiency and design flexibility drive overall cost benefits.

Design Flexibility and Customization

3D printed titanium offers superior design flexibility and customization compared to milled titanium, enabling the creation of complex geometries and intricate internal structures that are impossible to achieve with traditional subtractive methods. The additive process allows for layer-by-layer fabrication, which supports rapid prototyping and bespoke designs tailored to specific patient or application needs. Milled titanium remains limited by tool path constraints and material wastage, restricting its adaptability in producing highly personalized components.

Environmental Impact and Sustainability

3D printed titanium reduces material waste by using additive manufacturing techniques, which contrasts with the subtractive milling process that generates significant titanium scrap. The energy consumption of 3D printing in titanium production is generally lower, contributing to a smaller carbon footprint compared to traditional milling operations that require extensive machining. Sustainability is enhanced in 3D printed titanium due to optimized material use and the potential for on-demand manufacturing, minimizing inventory and transportation emissions.

Applications: Choosing the Right Titanium Manufacturing Technique

3D printed titanium offers complex geometries and lightweight structures ideal for aerospace components and customized medical implants, while milled titanium provides superior surface finish and mechanical properties suited for high-strength automotive and industrial parts. Selecting the right titanium manufacturing technique depends on specific application requirements such as precision, weight reduction, and production volume. Industries like aerospace, healthcare, and automotive leverage 3D printing for intricate designs and milling for durability and finish in critical load-bearing applications.

3D Printed Titanium vs Milled Titanium Infographic

materialdif.com

materialdif.com