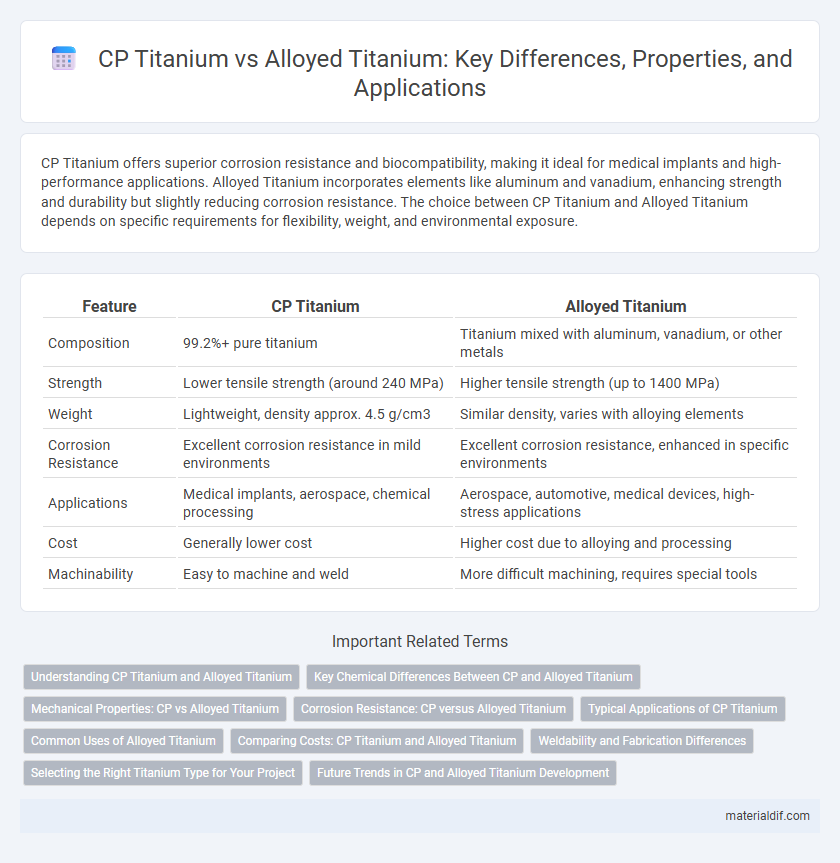

CP Titanium offers superior corrosion resistance and biocompatibility, making it ideal for medical implants and high-performance applications. Alloyed Titanium incorporates elements like aluminum and vanadium, enhancing strength and durability but slightly reducing corrosion resistance. The choice between CP Titanium and Alloyed Titanium depends on specific requirements for flexibility, weight, and environmental exposure.

Table of Comparison

| Feature | CP Titanium | Alloyed Titanium |

|---|---|---|

| Composition | 99.2%+ pure titanium | Titanium mixed with aluminum, vanadium, or other metals |

| Strength | Lower tensile strength (around 240 MPa) | Higher tensile strength (up to 1400 MPa) |

| Weight | Lightweight, density approx. 4.5 g/cm3 | Similar density, varies with alloying elements |

| Corrosion Resistance | Excellent corrosion resistance in mild environments | Excellent corrosion resistance, enhanced in specific environments |

| Applications | Medical implants, aerospace, chemical processing | Aerospace, automotive, medical devices, high-stress applications |

| Cost | Generally lower cost | Higher cost due to alloying and processing |

| Machinability | Easy to machine and weld | More difficult machining, requires special tools |

Understanding CP Titanium and Alloyed Titanium

CP Titanium, also known as commercially pure titanium, offers excellent corrosion resistance and high ductility, making it ideal for chemical processing and biomedical implants. Alloyed titanium combines titanium with elements like aluminum, vanadium, or molybdenum to enhance strength, heat resistance, and mechanical performance suitable for aerospace and automotive applications. Understanding the differences in composition and properties between CP Titanium and alloyed titanium is essential for selecting the right material based on specific engineering requirements.

Key Chemical Differences Between CP and Alloyed Titanium

CP Titanium primarily consists of nearly pure titanium (99% or higher) with minimal impurities, resulting in excellent corrosion resistance and biocompatibility. Alloyed titanium contains significant amounts of elements like aluminum, vanadium, iron, and molybdenum, which enhance strength, hardness, and thermal stability but may reduce corrosion resistance compared to CP Titanium. The key chemical difference lies in CP Titanium's purity versus the intentional incorporation of alloying elements in alloyed titanium to tailor mechanical properties for specific industrial applications.

Mechanical Properties: CP vs Alloyed Titanium

Commercially pure (CP) titanium exhibits excellent corrosion resistance and moderate tensile strength, typically ranging from 344 to 689 MPa, making it suitable for applications requiring biocompatibility and resistance to harsh environments. Alloyed titanium, such as Ti-6Al-4V, significantly enhances mechanical properties with tensile strengths exceeding 900 MPa and improved fatigue resistance due to aluminum and vanadium additions. The increased strength and hardness of alloyed titanium make it preferable for aerospace and high-performance engineering applications where superior mechanical durability is critical.

Corrosion Resistance: CP versus Alloyed Titanium

CP Titanium exhibits exceptional corrosion resistance in various environments due to its high purity and stable oxide layer, making it ideal for medical implants and chemical processing equipment. Alloyed Titanium, while offering increased strength and improved mechanical properties, may experience slightly reduced corrosion resistance depending on the alloying elements like aluminum and vanadium. The balance between corrosion resistance and mechanical performance is critical when selecting CP Titanium or Alloyed Titanium for specific industrial applications.

Typical Applications of CP Titanium

CP Titanium, or commercially pure titanium, is widely used in medical implants, aerospace components, and chemical processing equipment due to its excellent corrosion resistance and biocompatibility. Its typical applications include surgical instruments, dental implants, and aircraft structural parts where strength combined with lightweight properties is crucial. Compared to alloyed titanium, CP Titanium offers superior formability and weldability, making it ideal for seamless fabrication in demanding environments.

Common Uses of Alloyed Titanium

Alloyed titanium, known for its enhanced strength and corrosion resistance compared to commercially pure (CP) titanium, is commonly used in aerospace components, automotive parts, and medical implants. Its ability to withstand high stress and extreme environments makes it ideal for aircraft engines, airframes, and high-performance sports equipment. Industrial applications such as chemical processing plants and marine structures also rely heavily on alloyed titanium for durability and longevity.

Comparing Costs: CP Titanium and Alloyed Titanium

CP Titanium generally costs less than alloyed titanium due to its simpler composition and easier manufacturing processes. Alloyed titanium, enhanced with elements like aluminum and vanadium, offers superior strength and corrosion resistance but comes with higher production expenses. The cost difference significantly impacts applications where budget constraints are critical, such as aerospace and medical implants.

Weldability and Fabrication Differences

CP Titanium offers superior weldability due to its high purity and fewer alloying elements, resulting in fewer weld defects and easier fabrication. Alloyed titanium, containing elements like aluminum and vanadium, improves strength but requires stricter control during welding to avoid embrittlement and cracking. Fabrication of alloyed titanium demands specialized techniques such as controlled atmospheres and preheating, whereas CP Titanium can be welded using standard procedures with minimal post-weld treatment.

Selecting the Right Titanium Type for Your Project

Choosing between CP Titanium and alloyed titanium depends on project requirements such as strength, corrosion resistance, and weight. CP Titanium offers excellent corrosion resistance and biocompatibility ideal for medical implants and chemical processing equipment. Alloyed titanium provides higher strength and fatigue resistance, making it suitable for aerospace components and automotive applications.

Future Trends in CP and Alloyed Titanium Development

Future trends in CP Titanium emphasize enhanced purity and improved biocompatibility for medical implants, driven by advancements in electron beam melting and additive manufacturing technologies. Alloyed Titanium developments focus on optimizing strength-to-weight ratios through novel alloy compositions like Ti-6Al-7Nb and beta titanium alloys, targeting aerospace and automotive applications. Emerging research prioritizes sustainable production methods and recyclability, aiming to reduce environmental impact while maintaining superior mechanical properties.

CP Titanium vs Alloyed Titanium Infographic

materialdif.com

materialdif.com