SPF (Superplastic Forming) offers superior flexibility and precision in shaping titanium pet components compared to conventional forming, enabling complex geometries with minimal material waste. The process utilizes elevated temperatures to enhance titanium's ductility, resulting in uniform thickness and improved mechanical properties. Conventional forming often leads to greater residual stresses and dimensional inaccuracies, making SPF the preferred method for high-performance titanium pet manufacturing.

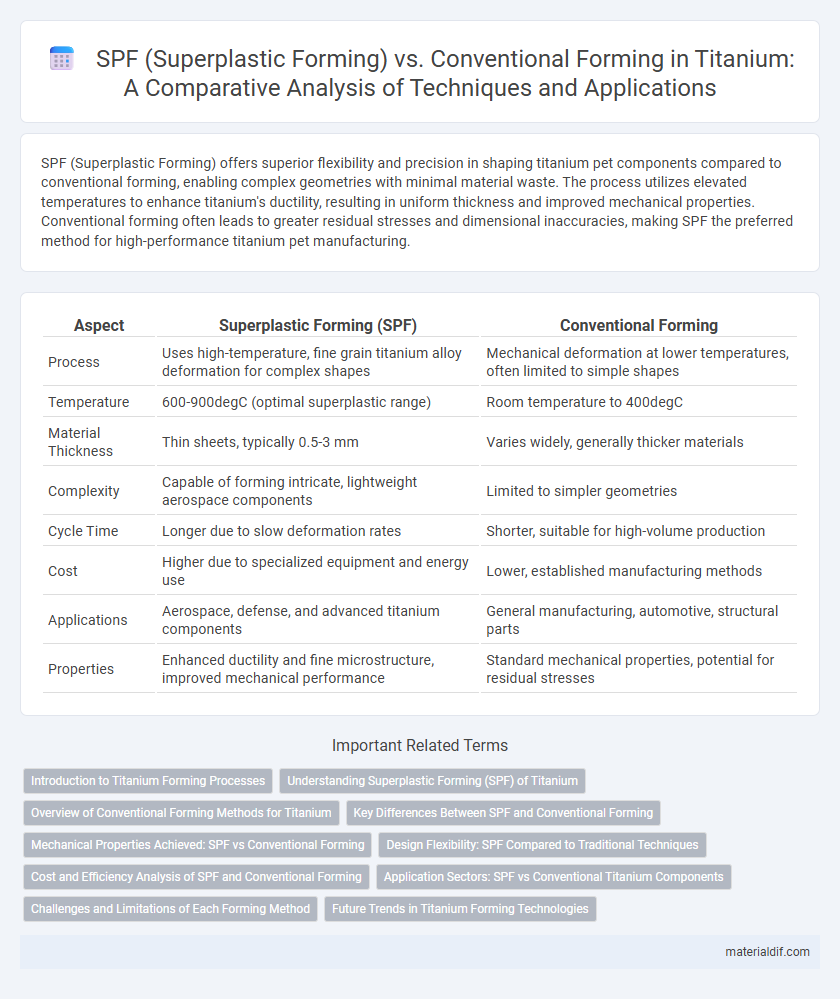

Table of Comparison

| Aspect | Superplastic Forming (SPF) | Conventional Forming |

|---|---|---|

| Process | Uses high-temperature, fine grain titanium alloy deformation for complex shapes | Mechanical deformation at lower temperatures, often limited to simple shapes |

| Temperature | 600-900degC (optimal superplastic range) | Room temperature to 400degC |

| Material Thickness | Thin sheets, typically 0.5-3 mm | Varies widely, generally thicker materials |

| Complexity | Capable of forming intricate, lightweight aerospace components | Limited to simpler geometries |

| Cycle Time | Longer due to slow deformation rates | Shorter, suitable for high-volume production |

| Cost | Higher due to specialized equipment and energy use | Lower, established manufacturing methods |

| Applications | Aerospace, defense, and advanced titanium components | General manufacturing, automotive, structural parts |

| Properties | Enhanced ductility and fine microstructure, improved mechanical performance | Standard mechanical properties, potential for residual stresses |

Introduction to Titanium Forming Processes

Superplastic forming (SPF) of titanium allows complex shapes to be produced with fine surface finishes and minimal springback by exploiting the material's high ductility at elevated temperatures, typically around 900degC. Conventional forming processes such as rolling, forging, and stamping operate at lower temperatures and often require multiple steps to achieve the desired geometry, leading to increased processing time and potential for defects. SPF enhances forming capabilities for aerospace-grade titanium alloys like Ti-6Al-4V, reducing material waste and improving structural integrity compared to traditional methods.

Understanding Superplastic Forming (SPF) of Titanium

Superplastic Forming (SPF) of titanium involves heating the titanium alloy to a temperature between 900degC and 950degC, where it exhibits exceptional ductility, allowing it to be stretched into complex shapes without cracking. SPF enables the production of lightweight, high-strength titanium components with superior dimensional accuracy and reduced residual stresses compared to conventional forming methods like forging and rolling. This process significantly enhances material utilization and design flexibility in aerospace and automotive industries by creating thin-walled titanium parts with intricate geometries that are difficult to achieve through traditional techniques.

Overview of Conventional Forming Methods for Titanium

Conventional forming methods for titanium primarily include rolling, forging, and extrusion, each facilitating the shaping of titanium alloys through plastic deformation under controlled temperature and pressure conditions. These processes rely on the inherent ductility and strength of titanium alloys but often require higher forces and yield limited geometric complexity compared to superplastic forming (SPF). The temperature range for conventional forming typically spans 600-900degC, optimizing mechanical properties while minimizing the risk of cracking and microstructural defects.

Key Differences Between SPF and Conventional Forming

SPF (Superplastic Forming) utilizes the exceptional superplasticity of titanium alloys at elevated temperatures, allowing complex shapes to be formed with minimal thinning and reduced tooling stress, unlike Conventional Forming which relies on mechanical deformation at lower temperatures leading to higher risk of cracking or springback. SPF achieves superior dimensional accuracy and surface finish due to its slow deformation process, while Conventional Forming often requires secondary operations for surface corrections and dimensional control. The process cycle time in SPF is generally longer, but it enables the fabrication of intricate aerospace components that are difficult to produce with Conventional Forming methods.

Mechanical Properties Achieved: SPF vs Conventional Forming

Superplastic Forming (SPF) of titanium alloys achieves superior mechanical properties compared to conventional forming methods, including enhanced ductility and uniform grain refinement. SPF processing results in lower residual stresses and improved strength-to-weight ratios, critical for aerospace applications. Conventional forming often leads to anisotropy and localized deformation, limiting the mechanical performance of titanium components.

Design Flexibility: SPF Compared to Traditional Techniques

Superplastic forming (SPF) offers superior design flexibility for titanium components by enabling complex geometries and intricate shapes that conventional forming techniques struggle to achieve. SPF utilizes high-temperature deformation, allowing uniform thinning and enhanced material flow, which reduces springback and residual stress in titanium parts. This results in lightweight, integrated structures with optimized mechanical properties, ideal for aerospace and automotive applications where performance and weight are critical.

Cost and Efficiency Analysis of SPF and Conventional Forming

Superplastic Forming (SPF) of titanium offers superior material efficiency by enabling complex shapes with fewer manufacturing steps compared to conventional forming, reducing overall production time and material waste. Despite higher initial equipment and tool costs, SPF lowers long-term expenses through decreased tooling wear and minimized part assembly requirements. Conventional forming remains more cost-effective for simple geometries and high-volume production due to faster cycle times and established manufacturing infrastructure.

Application Sectors: SPF vs Conventional Titanium Components

Superplastic Forming (SPF) enables the production of complex, lightweight titanium components ideal for aerospace and automotive sectors, offering enhanced design flexibility and material efficiency compared to conventional forming methods. Conventional titanium forming remains prevalent in industries like medical implants and industrial equipment, where cost-effectiveness and established production techniques are prioritized. SPF titanium components exhibit superior aerodynamic and structural performance, making them essential in high-performance aerospace applications demanding precision and weight reduction.

Challenges and Limitations of Each Forming Method

Superplastic Forming (SPF) of titanium allows for complex shapes with fine detail due to titanium's exceptional ductility at elevated temperatures but faces challenges such as expensive equipment, longer cycle times, and strict temperature control requirements to prevent grain growth and loss of mechanical properties. Conventional forming methods, including forging and rolling, offer faster production rates and lower costs but struggle with limited formability and increased risk of defects like cracking or residual stress due to titanium's high strength and low room-temperature ductility. Both methods require careful process optimization to balance material performance with manufacturing efficiency in aerospace and automotive titanium applications.

Future Trends in Titanium Forming Technologies

Superplastic forming (SPF) of titanium enables complex geometries with fine microstructures, significantly reducing waste compared to conventional forming techniques. Future trends emphasize combining SPF with additive manufacturing to enhance customization, reduce lead times, and improve mechanical properties. Advanced simulations and AI-driven process controls are emerging to optimize forming parameters, further boosting efficiency and component performance in aerospace and biomedical titanium applications.

SPF (Superplastic Forming) vs Conventional Forming Infographic

materialdif.com

materialdif.com