Anodized titanium offers enhanced corrosion resistance and a vibrant range of colors due to its oxide layer, making it ideal for decorative or personalized titanium pet products. Polished titanium, on the other hand, showcases a sleek, shiny finish that emphasizes durability and a classic metallic appearance, preferred for minimalist or high-end designs. Both finishes maintain titanium's lightweight strength and biocompatibility, ensuring long-lasting comfort and resilience for pets.

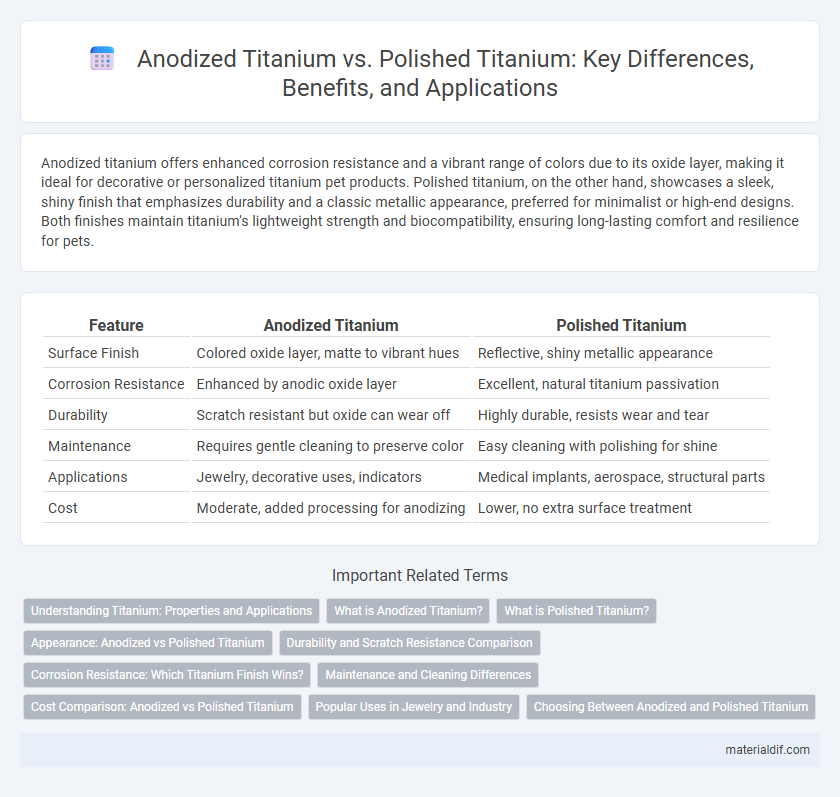

Table of Comparison

| Feature | Anodized Titanium | Polished Titanium |

|---|---|---|

| Surface Finish | Colored oxide layer, matte to vibrant hues | Reflective, shiny metallic appearance |

| Corrosion Resistance | Enhanced by anodic oxide layer | Excellent, natural titanium passivation |

| Durability | Scratch resistant but oxide can wear off | Highly durable, resists wear and tear |

| Maintenance | Requires gentle cleaning to preserve color | Easy cleaning with polishing for shine |

| Applications | Jewelry, decorative uses, indicators | Medical implants, aerospace, structural parts |

| Cost | Moderate, added processing for anodizing | Lower, no extra surface treatment |

Understanding Titanium: Properties and Applications

Anodized titanium exhibits enhanced corrosion resistance and vibrant color variations due to its controlled oxide layer, making it ideal for aerospace components and decorative applications. Polished titanium offers a sleek, reflective surface with superior biocompatibility, commonly used in medical implants and jewelry. Understanding the distinct surface treatments highlights how titanium's lightweight strength and corrosion resistance adapt to diverse industrial and aesthetic demands.

What is Anodized Titanium?

Anodized titanium is a surface-treated metal created by an electrochemical process that enhances corrosion resistance and introduces vibrant, durable color options without paint or dyes. Unlike polished titanium, which has a smooth, reflective finish achieved through mechanical buffing, anodized titanium forms a controlled oxide layer that alters its optical properties for aesthetic and functional benefits. This oxide layer also increases scratch resistance and extends the lifespan of titanium components used in jewelry, medical devices, and aerospace applications.

What is Polished Titanium?

Polished titanium is a surface finish achieved by buffing and smoothing the metal to create a reflective, mirror-like appearance that enhances its natural luster. This process removes surface impurities and imperfections, resulting in a highly durable, corrosion-resistant finish ideal for jewelry, medical implants, and aerospace components. Compared to anodized titanium, polished titanium retains its metallic silver color without the addition of oxide layer colors, offering a classic and sleek look.

Appearance: Anodized vs Polished Titanium

Anodized titanium features a vibrant, iridescent surface created by an electrochemical process that enhances color variation and offers a unique, eye-catching appearance. Polished titanium boasts a sleek, mirror-like finish that highlights the metal's natural silver-gray luster and provides a classic, elegant look. Both finishes increase titanium's aesthetic appeal, but anodized titanium stands out for its customizable color palette, while polished titanium emphasizes smoothness and reflective quality.

Durability and Scratch Resistance Comparison

Anodized titanium offers enhanced scratch resistance compared to polished titanium due to its protective oxide layer, which increases surface hardness and durability. Polished titanium, while visually appealing with a smooth, reflective finish, is more susceptible to scratches and wear over time. The anodizing process also helps titanium maintain its structural integrity in harsh environments, making it ideal for applications requiring long-lasting surface protection.

Corrosion Resistance: Which Titanium Finish Wins?

Anodized titanium offers superior corrosion resistance due to the thick oxide layer formed during the anodizing process, which acts as a protective barrier against environmental factors. Polished titanium, while visually appealing with its smooth, reflective surface, has a thinner natural oxide film, making it more susceptible to corrosion over time. For applications requiring enhanced durability and resistance to harsh conditions, anodized titanium is the optimal finish choice.

Maintenance and Cleaning Differences

Anodized titanium features a durable oxide layer that resists corrosion and scratches, significantly reducing maintenance needs compared to polished titanium, which is more prone to surface wear and visible smudges. Cleaning anodized titanium requires only gentle wiping with mild soap and water to preserve its color and protective coating. Polished titanium demands more frequent cleaning with non-abrasive agents and careful polishing to maintain its shiny, reflective finish.

Cost Comparison: Anodized vs Polished Titanium

Anodized titanium typically incurs lower production costs compared to polished titanium due to reduced labor and equipment expenses involved in chemical or electrochemical surface treatment. Polished titanium demands extensive mechanical polishing, increasing both processing time and operational costs, which results in higher market prices. Cost efficiency in anodized titanium makes it a preferred choice for applications requiring color customization and corrosion resistance without the premium price of a mirror-like finish.

Popular Uses in Jewelry and Industry

Anodized titanium is widely used in jewelry for its vibrant, customizable colors and enhanced corrosion resistance, making it ideal for fashion rings, earrings, and watches. Polished titanium, favored in industrial applications, offers a sleek, reflective surface and superior strength, commonly utilized in aerospace components, medical implants, and high-performance engineering parts. Both finishes exploit titanium's lightweight and durable properties but cater to distinct aesthetic and functional demands across jewelry and industry sectors.

Choosing Between Anodized and Polished Titanium

Choosing between anodized and polished titanium depends on the desired appearance and performance characteristics. Anodized titanium offers enhanced corrosion resistance and a wide range of vibrant colors due to its oxide layer, making it ideal for aesthetic customization and protective applications. Polished titanium features a sleek, reflective surface with excellent durability and biocompatibility, preferred for medical instruments and jewelry requiring a classic metallic finish.

Anodized Titanium vs Polished Titanium Infographic

materialdif.com

materialdif.com