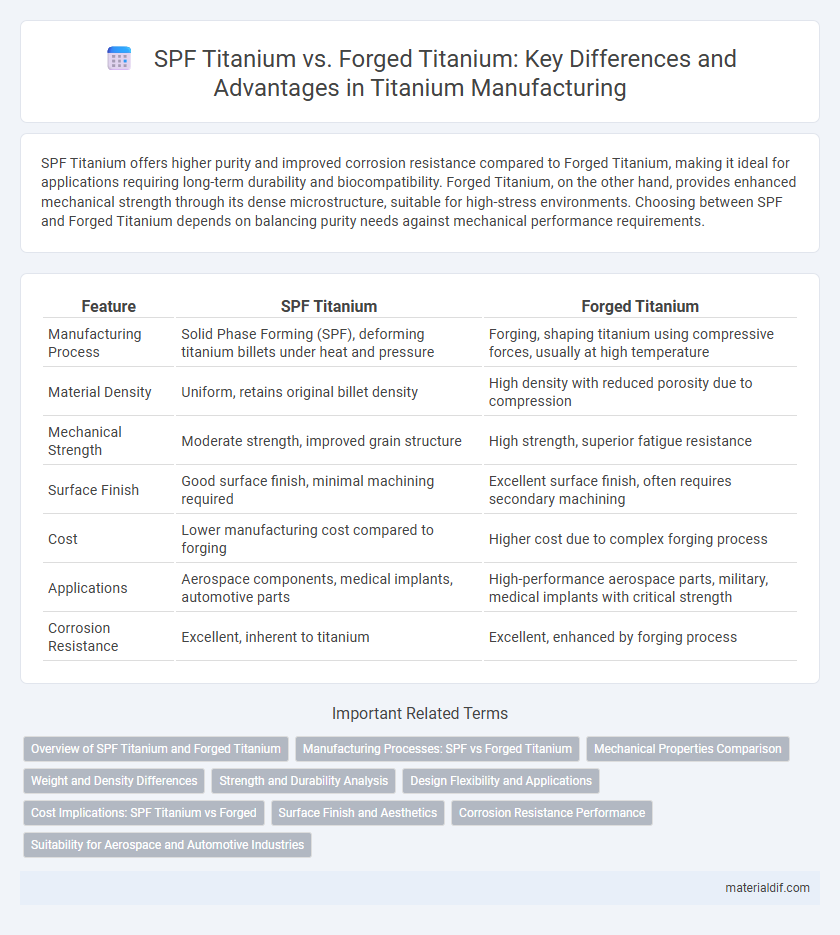

SPF Titanium offers higher purity and improved corrosion resistance compared to Forged Titanium, making it ideal for applications requiring long-term durability and biocompatibility. Forged Titanium, on the other hand, provides enhanced mechanical strength through its dense microstructure, suitable for high-stress environments. Choosing between SPF and Forged Titanium depends on balancing purity needs against mechanical performance requirements.

Table of Comparison

| Feature | SPF Titanium | Forged Titanium |

|---|---|---|

| Manufacturing Process | Solid Phase Forming (SPF), deforming titanium billets under heat and pressure | Forging, shaping titanium using compressive forces, usually at high temperature |

| Material Density | Uniform, retains original billet density | High density with reduced porosity due to compression |

| Mechanical Strength | Moderate strength, improved grain structure | High strength, superior fatigue resistance |

| Surface Finish | Good surface finish, minimal machining required | Excellent surface finish, often requires secondary machining |

| Cost | Lower manufacturing cost compared to forging | Higher cost due to complex forging process |

| Applications | Aerospace components, medical implants, automotive parts | High-performance aerospace parts, military, medical implants with critical strength |

| Corrosion Resistance | Excellent, inherent to titanium | Excellent, enhanced by forging process |

Overview of SPF Titanium and Forged Titanium

SPF titanium, or sponge powder forged titanium, is produced by compacting titanium sponge into a dense billet, offering superior purity and uniform mechanical properties ideal for aerospace and medical applications. Forged titanium involves shaping heated titanium billets through mechanical deformation, resulting in enhanced strength and fatigue resistance due to refined grain structure. Both processes yield high-performance titanium materials, but SPF titanium emphasizes controlled microstructure for critical components, while forged titanium is preferred for its toughness and structural integrity in heavy-duty environments.

Manufacturing Processes: SPF vs Forged Titanium

SPF Titanium is produced through Spray Forming Process, where molten titanium is atomized and deposited onto a substrate, resulting in fine-grained microstructures and reduced segregation. Forged Titanium, on the other hand, undergoes plastic deformation under high pressure at elevated temperatures, enhancing mechanical properties by aligning grain flow and refining grain size. The Spray Forming Process offers better uniformity and reduced waste, while forging provides superior strength and toughness through controlled grain orientation.

Mechanical Properties Comparison

SPF titanium exhibits a finer grain structure due to the Superplastic Forming process, resulting in enhanced ductility and better fatigue resistance compared to forged titanium. Forged titanium typically offers higher tensile strength and improved yield strength because of the controlled deformation and work hardening during forging. Mechanical properties such as toughness and impact resistance vary depending on processing parameters, with SPF titanium excelling in complex, lightweight aerospace components where formability and fatigue life are critical.

Weight and Density Differences

SPF Titanium, produced through superplastic forming, exhibits lower density and reduced weight compared to Forged Titanium due to its unique microstructure and manufacturing process. Forged Titanium, known for superior strength and durability, typically has a higher density, resulting in added weight. These differences in weight and density influence applications where balance between strength and lightweight performance is critical, such as aerospace and medical implants.

Strength and Durability Analysis

SPF Titanium offers superior purity and consistent grain structure, resulting in enhanced strength and fatigue resistance compared to Forged Titanium. Forged Titanium, while durable, may exhibit variable grain sizes due to the forging process, potentially impacting its toughness under cyclic loads. The uniform microstructure of SPF Titanium ensures better long-term durability for critical aerospace and biomedical applications.

Design Flexibility and Applications

SPF titanium offers enhanced design flexibility due to its fine grain structure, enabling complex shapes and thin-walled components ideal for aerospace and medical implants. Forged titanium provides superior strength and toughness, making it suitable for heavy-duty applications like automotive parts and structural components. The choice between SPF and forged titanium depends on balancing intricate design requirements with mechanical performance needs.

Cost Implications: SPF Titanium vs Forged

SPF titanium typically incurs lower production costs due to its powder metallurgy process, reducing material waste and energy consumption compared to forged titanium. Forged titanium demands higher expenses in tooling, machining, and labor, resulting in elevated overall manufacturing costs. Choosing SPF titanium can lead to significant cost savings in large-scale applications without compromising material properties.

Surface Finish and Aesthetics

SPF Titanium offers a smoother surface finish with fewer micro-imperfections due to its specialized processing, enhancing both durability and aesthetic appeal. Forged Titanium typically exhibits a more rugged texture and visible grain patterns, providing a distinct, raw visual character favored in heavy-duty applications. The superior polishability of SPF Titanium allows for higher gloss and refined aesthetics, making it ideal for premium, visually striking products.

Corrosion Resistance Performance

SPF titanium demonstrates superior corrosion resistance compared to forged titanium due to its refined microstructure and reduced grain boundary contamination, enhancing durability in aggressive environments. The powder metallurgy process used in SPF minimizes impurities and porosity, leading to improved resistance against chloride-induced stress corrosion cracking. Forged titanium, while strong, tends to have more heterogeneity in grain size and may be more susceptible to localized corrosion under harsh chemical exposures.

Suitability for Aerospace and Automotive Industries

SPF titanium, known for its superior fatigue resistance and lightweight properties, is highly suitable for aerospace applications requiring precise strength-to-weight ratios and corrosion resistance. Forged titanium offers enhanced mechanical strength and toughness, making it ideal for automotive components subjected to high stress and impact loads. Both materials meet stringent industry standards, but SPF titanium is preferred in aerospace due to its fine microstructure, while forged titanium is favored in automotive manufacturing for its durability and cost efficiency.

SPF Titanium vs Forged Titanium Infographic

materialdif.com

materialdif.com