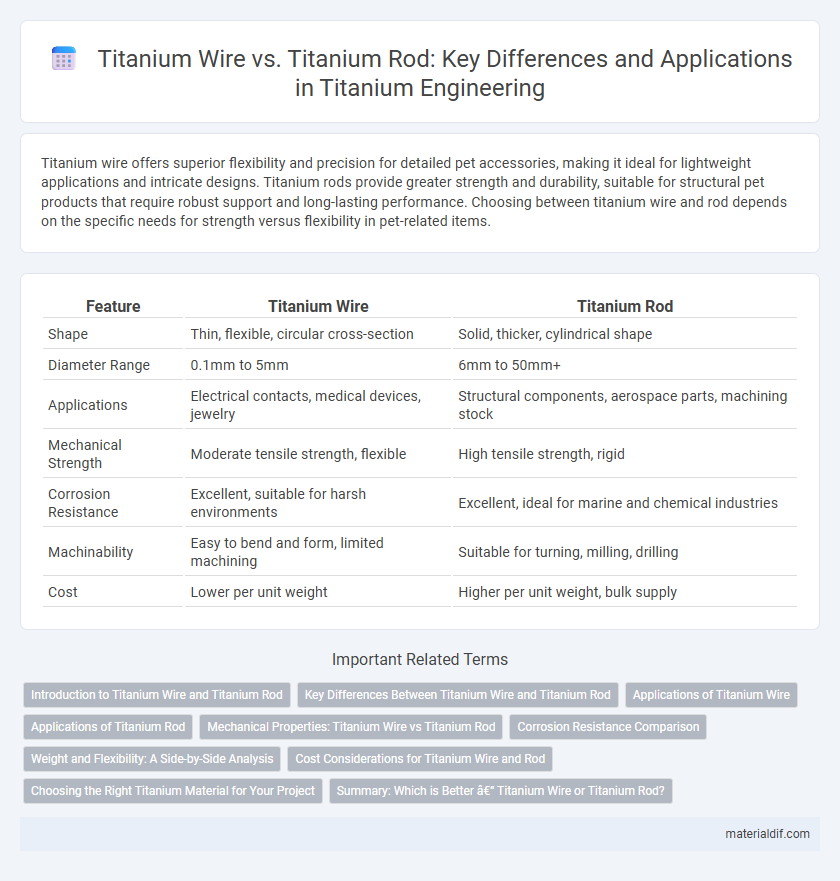

Titanium wire offers superior flexibility and precision for detailed pet accessories, making it ideal for lightweight applications and intricate designs. Titanium rods provide greater strength and durability, suitable for structural pet products that require robust support and long-lasting performance. Choosing between titanium wire and rod depends on the specific needs for strength versus flexibility in pet-related items.

Table of Comparison

| Feature | Titanium Wire | Titanium Rod |

|---|---|---|

| Shape | Thin, flexible, circular cross-section | Solid, thicker, cylindrical shape |

| Diameter Range | 0.1mm to 5mm | 6mm to 50mm+ |

| Applications | Electrical contacts, medical devices, jewelry | Structural components, aerospace parts, machining stock |

| Mechanical Strength | Moderate tensile strength, flexible | High tensile strength, rigid |

| Corrosion Resistance | Excellent, suitable for harsh environments | Excellent, ideal for marine and chemical industries |

| Machinability | Easy to bend and form, limited machining | Suitable for turning, milling, drilling |

| Cost | Lower per unit weight | Higher per unit weight, bulk supply |

Introduction to Titanium Wire and Titanium Rod

Titanium wire offers exceptional flexibility and precision for applications requiring fine detail and intricate designs, commonly used in medical devices and electronics. Titanium rod provides superior strength and durability, making it ideal for structural components in aerospace and industrial machinery. Both forms leverage titanium's corrosion resistance and high strength-to-weight ratio but serve different functional needs based on their shape and processing methods.

Key Differences Between Titanium Wire and Titanium Rod

Titanium wire offers superior flexibility and is often used in applications requiring intricate bends or fine detailing, while titanium rod provides greater strength and rigidity, making it ideal for structural and load-bearing purposes. Titanium wire typically features a smaller diameter and simpler fabrication compared to the thicker, solid cross-section of titanium rods. The choice between titanium wire and rod depends on specific mechanical property requirements such as tensile strength, ductility, and the nature of the industrial application.

Applications of Titanium Wire

Titanium wire is extensively utilized in medical devices, aerospace components, and electrical applications due to its high strength-to-weight ratio and excellent corrosion resistance. Its flexibility and ability to be drawn into fine gauges make it ideal for surgical implants, orthodontic devices, and precision springs. In contrast, titanium rods are preferred for structural and load-bearing applications where rigidity and bulk material properties are essential.

Applications of Titanium Rod

Titanium rods are extensively used in aerospace, automotive, and medical fields due to their superior strength-to-weight ratio and corrosion resistance, making them ideal for structural components and implants. Unlike titanium wire, which is primarily used for fine applications like electronics and jewelry, titanium rods provide the necessary rigidity and dimensional stability required in heavy-duty engineering and manufacturing processes. Their applications include aircraft frameworks, marine equipment, and surgical prosthetics, where durability and biocompatibility are critical.

Mechanical Properties: Titanium Wire vs Titanium Rod

Titanium wire exhibits higher tensile strength and flexibility compared to titanium rod, making it ideal for applications requiring durability and intricate shaping. Titanium rods provide greater rigidity and compression resistance, suitable for structural and load-bearing uses. The choice between titanium wire and rod depends on the mechanical property demands, such as flexibility for wire or stiffness for rod.

Corrosion Resistance Comparison

Titanium wire exhibits superior corrosion resistance compared to titanium rod due to its increased surface area and finer grain structure, which enhances its passivation layer. Both materials resist corrosion in aggressive environments such as seawater and chemical processing, but the wire's form factor allows for quicker oxide film regeneration after damage. Choosing titanium wire over rod is advantageous in applications requiring maximum durability against pitting, crevice corrosion, and stress corrosion cracking.

Weight and Flexibility: A Side-by-Side Analysis

Titanium wire offers superior flexibility compared to titanium rod due to its thinner diameter and ability to bend without breaking, making it ideal for applications requiring precise shaping and lightweight components. Titanium rod, while heavier and less flexible, provides greater structural strength and rigidity, suited for load-bearing uses where durability is critical. In terms of weight, titanium wire is significantly lighter, enhancing performance in aerospace and medical devices where minimizing mass is crucial.

Cost Considerations for Titanium Wire and Rod

Titanium wire typically costs less per unit weight than titanium rod due to its manufacturing process and lower material density. Rods require more extensive machining and higher material volume, resulting in increased overall expenses for larger or thicker applications. Budget planning for titanium components should account for these cost differences alongside specific project requirements and mechanical properties.

Choosing the Right Titanium Material for Your Project

Selecting between titanium wire and titanium rod depends primarily on the project's design requirements and mechanical needs. Titanium wire offers superior flexibility and is ideal for intricate applications like medical devices and fine electronics, while titanium rod provides enhanced strength and rigidity suitable for structural components and heavy-duty machinery. Understanding the specific grade, diameter, and tensile strength of each form ensures optimal performance and durability in aerospace, automotive, or industrial projects.

Summary: Which is Better – Titanium Wire or Titanium Rod?

Titanium wire offers superior flexibility and is ideal for applications requiring intricate shaping and detailed work, while titanium rod provides greater strength and rigidity, making it better suited for structural components and heavy-duty uses. Choosing between titanium wire and titanium rod depends on the specific requirements of tensile strength, flexibility, and application environment. For precision tasks such as medical devices and crafting, titanium wire excels, whereas titanium rod dominates in aerospace and industrial manufacturing due to its robust mechanical properties.

Titanium Wire vs Titanium Rod Infographic

materialdif.com

materialdif.com