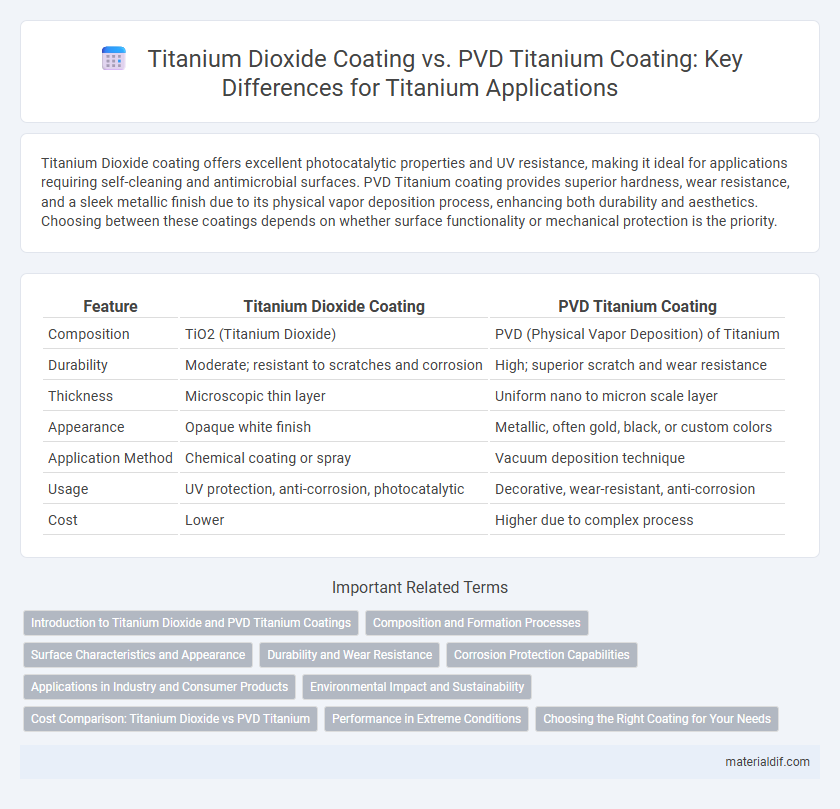

Titanium Dioxide coating offers excellent photocatalytic properties and UV resistance, making it ideal for applications requiring self-cleaning and antimicrobial surfaces. PVD Titanium coating provides superior hardness, wear resistance, and a sleek metallic finish due to its physical vapor deposition process, enhancing both durability and aesthetics. Choosing between these coatings depends on whether surface functionality or mechanical protection is the priority.

Table of Comparison

| Feature | Titanium Dioxide Coating | PVD Titanium Coating |

|---|---|---|

| Composition | TiO2 (Titanium Dioxide) | PVD (Physical Vapor Deposition) of Titanium |

| Durability | Moderate; resistant to scratches and corrosion | High; superior scratch and wear resistance |

| Thickness | Microscopic thin layer | Uniform nano to micron scale layer |

| Appearance | Opaque white finish | Metallic, often gold, black, or custom colors |

| Application Method | Chemical coating or spray | Vacuum deposition technique |

| Usage | UV protection, anti-corrosion, photocatalytic | Decorative, wear-resistant, anti-corrosion |

| Cost | Lower | Higher due to complex process |

Introduction to Titanium Dioxide and PVD Titanium Coatings

Titanium dioxide coatings offer exceptional corrosion resistance and UV protection, commonly used in paints and sunscreens due to their photocatalytic properties and high refractive index. PVD titanium coatings, created through Physical Vapor Deposition, provide a thin, uniform layer of titanium or titanium compounds that enhance surface hardness, wear resistance, and aesthetic appeal. Both coatings serve distinct industrial purposes, with titanium dioxide favored for chemical stability and UV blocking, while PVD titanium coatings excel in durability and decorative finishes.

Composition and Formation Processes

Titanium dioxide coating primarily consists of TiO2 particles formed through chemical or physical deposition methods such as sol-gel or spray pyrolysis, creating a ceramic layer known for its photocatalytic and UV-resistant properties. PVD titanium coating involves depositing a thin layer of metallic titanium or titanium-based alloys onto a substrate using physical vapor deposition techniques such as sputtering or evaporation, resulting in a dense, adherent, and uniformly thin metallic film. The formation process of titanium dioxide focuses on chemical transformation and oxidation, whereas PVD titanium coating relies on vacuum-based physical processes that enable precise control over thickness and microstructure.

Surface Characteristics and Appearance

Titanium Dioxide coating offers a matte finish with excellent corrosion resistance and UV protection, ideal for applications requiring durability and a non-reflective surface. PVD (Physical Vapor Deposition) Titanium coating provides a highly polished, metallic luster with superior hardness and wear resistance, enhancing both aesthetic appeal and functional performance. Surface characteristics of PVD coatings typically include higher uniformity and scratch resistance compared to the more porous and less dense Titanium Dioxide layer.

Durability and Wear Resistance

Titanium dioxide coating offers strong UV protection and corrosion resistance but is relatively softer and prone to scratching under heavy wear conditions. PVD (Physical Vapor Deposition) titanium coating provides superior durability and wear resistance due to its dense, hard ceramic-like layer that enhances surface hardness up to 90 HRC. This makes PVD titanium coatings ideal for high-performance applications requiring long-lasting scratch resistance and minimal abrasion.

Corrosion Protection Capabilities

Titanium dioxide coating offers moderate corrosion protection by forming a stable oxide layer that resists oxidation and chemical degradation. PVD titanium coating provides superior corrosion resistance due to its dense, adherent metallic layer that acts as a physical barrier against moisture and corrosive agents. The enhanced durability and longevity of PVD coatings make them ideal for harsh environments requiring robust corrosion protection.

Applications in Industry and Consumer Products

Titanium dioxide coating is widely used in industries requiring UV protection, photocatalytic properties, and corrosion resistance, particularly in paints, sunscreens, and self-cleaning surfaces. PVD titanium coating, offering superior hardness, wear resistance, and aesthetic appeal, is preferred for industrial cutting tools, medical devices, and consumer electronics casings. These coatings serve distinct functions: titanium dioxide enhances chemical stability and light interaction, while PVD layers improve mechanical durability and surface finish.

Environmental Impact and Sustainability

Titanium dioxide coatings are photocatalytic and can break down organic pollutants, enhancing environmental cleanliness but may contribute to nanoparticle release concerns. PVD (Physical Vapor Deposition) titanium coatings use vacuum technology, producing minimal waste and reducing hazardous chemical use, making them more sustainable in industrial applications. Both techniques impact sustainability differently, with PVD titanium coatings offering a greener manufacturing process and titanium dioxide coatings promoting pollution degradation.

Cost Comparison: Titanium Dioxide vs PVD Titanium

Titanium Dioxide coating typically offers a lower initial cost due to simpler manufacturing processes and cheaper raw materials, making it suitable for budget-conscious applications. PVD Titanium coating, though more expensive upfront, provides superior durability, corrosion resistance, and aesthetic quality, often justifying the higher investment in industrial and high-performance environments. Long-term cost efficiency favors PVD Titanium coatings as reduced maintenance and extended lifespan lower total ownership expenses compared to Titanium Dioxide alternatives.

Performance in Extreme Conditions

Titanium dioxide coating provides excellent corrosion resistance and UV protection, making it suitable for outdoor applications exposed to harsh weather and sunlight. PVD titanium coating offers superior hardness and durability, enhancing wear resistance and maintaining performance under high temperatures and abrasive environments. Both coatings improve titanium's longevity, but PVD titanium coating excels in extreme mechanical stress and thermal stability.

Choosing the Right Coating for Your Needs

Titanium dioxide coating offers superior UV protection and corrosion resistance, ideal for outdoor applications requiring durability against environmental elements. PVD titanium coating provides exceptional hardness and wear resistance, making it suitable for industrial tools and decorative finishes where scratch resistance is crucial. Selecting the right coating depends on whether your priority is environmental protection or mechanical strength, ensuring optimal performance for your specific application requirements.

Titanium Dioxide Coating vs PVD Titanium Coating Infographic

materialdif.com

materialdif.com