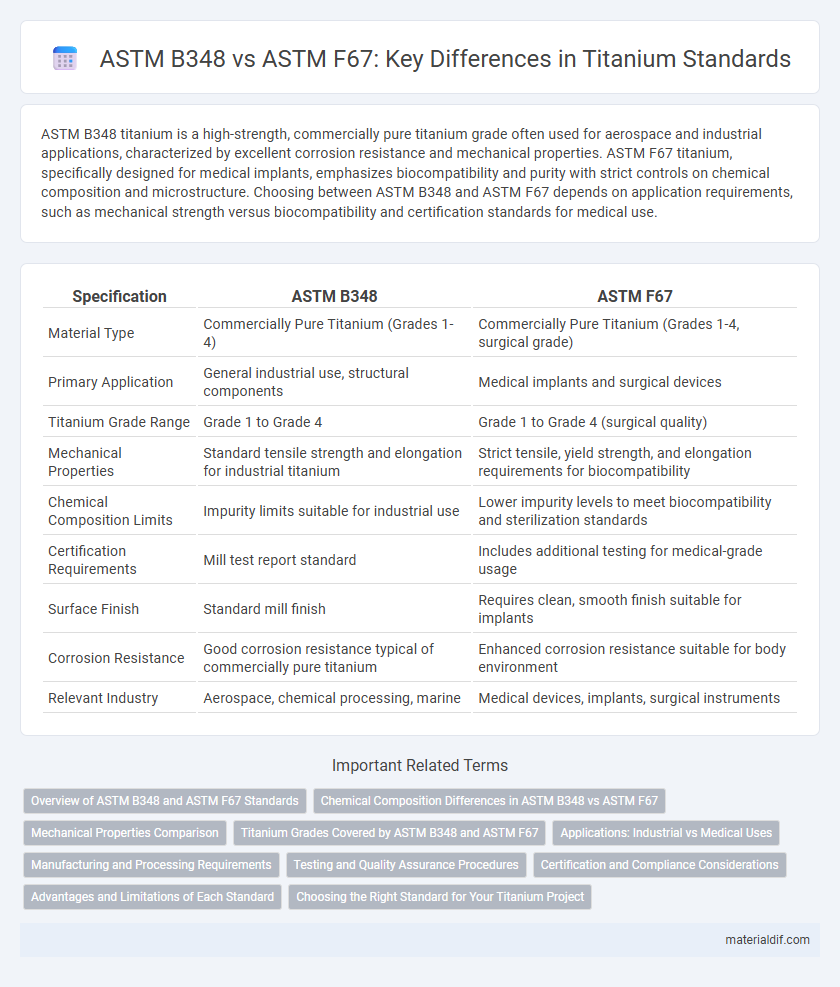

ASTM B348 titanium is a high-strength, commercially pure titanium grade often used for aerospace and industrial applications, characterized by excellent corrosion resistance and mechanical properties. ASTM F67 titanium, specifically designed for medical implants, emphasizes biocompatibility and purity with strict controls on chemical composition and microstructure. Choosing between ASTM B348 and ASTM F67 depends on application requirements, such as mechanical strength versus biocompatibility and certification standards for medical use.

Table of Comparison

| Specification | ASTM B348 | ASTM F67 |

|---|---|---|

| Material Type | Commercially Pure Titanium (Grades 1-4) | Commercially Pure Titanium (Grades 1-4, surgical grade) |

| Primary Application | General industrial use, structural components | Medical implants and surgical devices |

| Titanium Grade Range | Grade 1 to Grade 4 | Grade 1 to Grade 4 (surgical quality) |

| Mechanical Properties | Standard tensile strength and elongation for industrial titanium | Strict tensile, yield strength, and elongation requirements for biocompatibility |

| Chemical Composition Limits | Impurity limits suitable for industrial use | Lower impurity levels to meet biocompatibility and sterilization standards |

| Certification Requirements | Mill test report standard | Includes additional testing for medical-grade usage |

| Surface Finish | Standard mill finish | Requires clean, smooth finish suitable for implants |

| Corrosion Resistance | Good corrosion resistance typical of commercially pure titanium | Enhanced corrosion resistance suitable for body environment |

| Relevant Industry | Aerospace, chemical processing, marine | Medical devices, implants, surgical instruments |

Overview of ASTM B348 and ASTM F67 Standards

ASTM B348 specifies the standard for titanium and titanium alloy bars and billets primarily used in aerospace, medical, and industrial applications, emphasizing chemical composition, mechanical properties, and defect controls. ASTM F67 details the requirements for unalloyed titanium bars and billets intended for surgical implant applications, focusing on biocompatibility, microstructure, and trace element restrictions. Both standards ensure material quality and performance, with ASTM B348 covering a broader range of industrial uses and ASTM F67 tailored specifically for medical-grade titanium products.

Chemical Composition Differences in ASTM B348 vs ASTM F67

ASTM B348 titanium is primarily composed of commercially pure titanium grades with limits on oxygen, nitrogen, carbon, hydrogen, and iron, ensuring high corrosion resistance and strength. ASTM F67 specifies the chemical composition for unalloyed titanium used in surgical implants, with stricter controls on impurities like oxygen and iron to enhance biocompatibility. The key difference lies in the tighter impurity limits in ASTM F67, which optimize titanium's performance in medical applications compared to the broader chemical composition range allowed in ASTM B348.

Mechanical Properties Comparison

ASTM B348 specifies titanium alloys used for bars, rods, and billets primarily in Grades 1 through 4, offering tensile strengths ranging from 240 to 620 MPa depending on the grade. ASTM F67 focuses on commercially pure titanium for surgical implant applications, emphasizing high ductility and lower tensile strength, typically between 240 and 410 MPa. The key mechanical difference lies in ASTM B348's broader strength range suited for industrial uses, while ASTM F67 prioritizes biocompatibility and toughness for medical devices.

Titanium Grades Covered by ASTM B348 and ASTM F67

ASTM B348 specifies requirements for titanium and titanium alloy bars, covering commercial pure grades such as Grade 1, Grade 2, Grade 7, and Grade 12, commonly used in aerospace, medical, and industrial applications. ASTM F67 focuses specifically on unalloyed titanium, primarily Grade 1 through Grade 4, intended for surgical implant applications requiring high purity and biocompatibility. The key distinction lies in ASTM B348 addressing broader industrial titanium bars including alloys, while ASTM F67 targets medical-grade commercially pure titanium for implants.

Applications: Industrial vs Medical Uses

ASTM B348 titanium is primarily utilized in industrial applications such as aerospace, chemical processing, and marine environments due to its high strength and corrosion resistance. ASTM F67 titanium is specifically designed for medical applications, including surgical implants and prosthetics, because it meets biocompatibility standards and exhibits excellent corrosion resistance in body fluids. The distinct ASTM specifications reflect their tailored properties: ASTM B348 emphasizes mechanical strength for industrial durability, while ASTM F67 prioritizes purity and biocompatibility for safe medical use.

Manufacturing and Processing Requirements

ASTM B348 specifies requirements for titanium and titanium alloy bars, billets, and forgings used primarily in aerospace and industrial applications, emphasizing stringent chemical composition and mechanical properties for high-performance manufacturing. ASTM F67 covers unalloyed titanium for medical devices, focusing on biocompatibility and precise processing controls to ensure safe implant fabrication. Manufacturing under ASTM B348 involves rigorous heat treatment and testing to achieve enhanced strength and corrosion resistance, whereas ASTM F67 requires controlled annealing and surface finish standards to meet stringent medical-grade specifications.

Testing and Quality Assurance Procedures

ASTM B348 specifies rigorous testing methods for titanium products, including chemical composition analysis, tensile strength, impact resistance, and hardness tests to ensure material conformity for aerospace applications. ASTM F67 focuses on commercially pure titanium used in medical implants, emphasizing biocompatibility, microstructure evaluation, and corrosion resistance tests to meet stringent biomedical standards. Both standards enforce strict quality assurance protocols, but ASTM B348 targets mechanical and structural properties, while ASTM F67 prioritizes purity and compatibility for safe implant performance.

Certification and Compliance Considerations

ASTM B348 specifies the requirements for titanium and titanium alloy bars and billets primarily used in structural applications, ensuring strict compliance with mechanical properties and chemical composition standards for aerospace and industrial certifications. ASTM F67 focuses on unalloyed titanium forged and rolled bars intended for surgical implants, emphasizing biocompatibility and traceability certifications critical for medical device regulatory compliance. Selecting between ASTM B348 and ASTM F67 depends on whether the titanium material must meet aerospace-grade mechanical certifications or stringent medical-grade biocompatibility and sterilization standards.

Advantages and Limitations of Each Standard

ASTM B348 covers titanium and titanium alloy bars, billets, forgings, and other wrought products with superior strength and corrosion resistance, ideal for aerospace and industrial applications requiring high mechanical properties. ASTM F67 specifies unalloyed titanium forged and rolled bars for surgical implant applications prioritizing biocompatibility and purity but with more stringent defect controls and limited alloy options. While ASTM B348 offers broader mechanical versatility and alloy variety, ASTM F67 excels in medical-grade material purity, limiting its use to biomedical fields with stringent regulatory requirements.

Choosing the Right Standard for Your Titanium Project

ASTM B348 specifies requirements for titanium and titanium alloy bars, billets, and forgings typically used in aerospace, chemical, and marine applications, ensuring high strength and corrosion resistance. ASTM F67 covers unalloyed titanium for surgical implant applications, emphasizing biocompatibility and purity to prevent adverse body reactions. Selecting between ASTM B348 and ASTM F67 depends on project demands for mechanical properties versus medical-grade purity, guiding optimal titanium standard compliance.

ASTM B348 vs ASTM F67 Infographic

materialdif.com

materialdif.com