Titanium anodization enhances the metal's surface by creating a durable oxide layer that improves corrosion resistance and allows for vibrant color variations, ideal for personalized titanium pet accessories. Passivation, on the other hand, involves treating the titanium surface with acid to remove contaminants and naturally form a protective oxide layer, boosting corrosion resistance without altering the metal's appearance. Choosing anodization or passivation depends on whether aesthetic customization or maintaining a pristine, natural finish is the priority for titanium pet products.

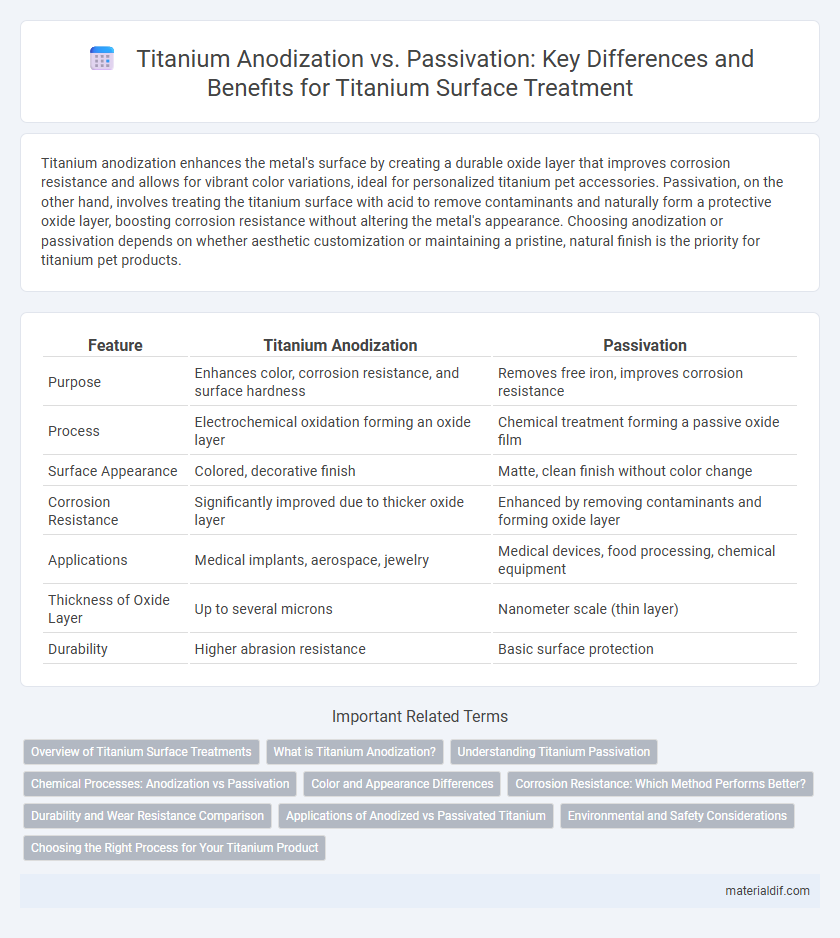

Table of Comparison

| Feature | Titanium Anodization | Passivation |

|---|---|---|

| Purpose | Enhances color, corrosion resistance, and surface hardness | Removes free iron, improves corrosion resistance |

| Process | Electrochemical oxidation forming an oxide layer | Chemical treatment forming a passive oxide film |

| Surface Appearance | Colored, decorative finish | Matte, clean finish without color change |

| Corrosion Resistance | Significantly improved due to thicker oxide layer | Enhanced by removing contaminants and forming oxide layer |

| Applications | Medical implants, aerospace, jewelry | Medical devices, food processing, chemical equipment |

| Thickness of Oxide Layer | Up to several microns | Nanometer scale (thin layer) |

| Durability | Higher abrasion resistance | Basic surface protection |

Overview of Titanium Surface Treatments

Titanium anodization enhances corrosion resistance and surface aesthetics by forming a thick, stable oxide layer through electrochemical oxidation, allowing for varied color finishes without paint. Passivation creates a thin, naturally occurring oxide film that protects titanium from corrosion by removing free iron and contaminants, maintaining its biocompatibility and durability. Both surface treatments improve titanium's performance but differ in process and application, with anodization offering decorative options and passivation focusing on chemical stability.

What is Titanium Anodization?

Titanium anodization is an electrochemical process that enhances the metal's surface by forming a durable oxide layer, improving corrosion resistance and enabling vibrant color finishes through controlled voltage application. This oxide layer is thicker and more uniform than the naturally occurring passive film created by passivation, providing superior protection against wear and environmental factors. Anodizing titanium also increases surface hardness and can be precisely controlled to achieve specific aesthetic and functional properties for aerospace, medical, and architectural applications.

Understanding Titanium Passivation

Titanium passivation creates a stable, protective oxide layer that enhances corrosion resistance by naturally forming on the metal's surface, preventing ion release and surface degradation. This chemical process is crucial for medical implants and aerospace components where biocompatibility and durability are essential. Passivation differs from anodization by preserving the metal's natural surface without altering color or thickness through electrical methods.

Chemical Processes: Anodization vs Passivation

Titanium anodization involves an electrochemical process that thickens the natural oxide layer on the titanium surface, enhancing corrosion resistance and allowing controlled color changes through interference effects. Passivation, by contrast, is a chemical treatment that forms a thin, stable oxide layer on titanium, primarily using acids to remove free iron and contaminants, improving the metal's corrosion resistance without altering surface appearance. Both processes improve titanium's durability, but anodization provides a thicker, more durable oxide layer with aesthetic advantages, while passivation focuses on surface cleanliness and corrosion inhibition.

Color and Appearance Differences

Titanium anodization creates a vibrant, colorful oxide layer by altering the metal's surface thickness, resulting in iridescent hues ranging from blue to purple, green, and gold. Passivation enhances corrosion resistance by removing contaminants and forming a clear, thin oxide layer without significantly changing the metal's natural silver-gray color. The anodized finish offers varied aesthetic appeal for decorative or functional applications, whereas passivation maintains titanium's original appearance while improving durability.

Corrosion Resistance: Which Method Performs Better?

Titanium anodization enhances corrosion resistance by forming a thick, stable oxide layer that protects the metal from aggressive environments, making it ideal for biomedical and aerospace applications. In contrast, passivation improves corrosion resistance by chemically removing surface contaminants and promoting a thin, natural oxide layer, which offers less robust protection compared to anodization. Studies indicate that anodized titanium consistently outperforms passivated surfaces in corrosion resistance, especially in chloride-rich or acidic conditions.

Durability and Wear Resistance Comparison

Titanium anodization enhances surface hardness and corrosion resistance by forming a thick oxide layer, significantly improving wear resistance and durability in harsh environments. Passivation creates a thin, protective oxide film that stabilizes the metal but offers less mechanical wear resistance compared to anodization. For applications requiring superior abrasion resistance and prolonged lifespan, anodized titanium surfaces outperform passivated ones due to their enhanced oxide thickness and hardness.

Applications of Anodized vs Passivated Titanium

Anodized titanium is widely used in biomedical implants and aerospace components due to its enhanced corrosion resistance and vibrant color options for easy identification. Passivated titanium serves primarily in chemical processing and marine environments where a stable oxide layer ensures long-term protection against aggressive corrosion. Both treatments improve durability, but anodization offers customization in surface properties, whereas passivation emphasizes chemical stability.

Environmental and Safety Considerations

Titanium anodization involves an electrochemical process that enhances corrosion resistance and surface hardness by forming a controlled oxide layer, generating minimal hazardous waste when properly managed. Passivation, on the other hand, relies on chemical treatments, often using nitric acid, to create a passive oxide film that improves corrosion resistance but requires careful handling of acidic and potentially toxic effluents. Both processes demand stringent safety protocols to reduce environmental impact, with anodization generally favored for lower chemical consumption and easier waste neutralization.

Choosing the Right Process for Your Titanium Product

Selecting the right surface treatment for titanium products hinges on understanding anodization and passivation differences; anodization enhances corrosion resistance and allows vibrant color finishes by forming a thick oxide layer, while passivation chemically removes contaminants to boost the natural oxide layer's protective qualities without altering appearance. Anodization suits applications requiring aesthetic customization and improved wear resistance, especially in medical implants and aerospace components. Passivation is ideal for maintaining titanium's biocompatibility and corrosion resistance in environments where minimal surface modification is preferred, such as in chemical processing or surgical tools.

Titanium Anodization vs Passivation Infographic

materialdif.com

materialdif.com