Tin whisker formation and tin pest are both phenomena affecting the reliability of tin coatings, yet they differ fundamentally in causes and effects. Tin whiskers are tiny, hair-like metallic growths that emerge from pure tin surfaces, potentially causing short circuits in electronic devices. In contrast, tin pest is a low-temperature phase transformation of tin, leading to brittleness and disintegration, primarily occurring below 13degC in gray tin.

Table of Comparison

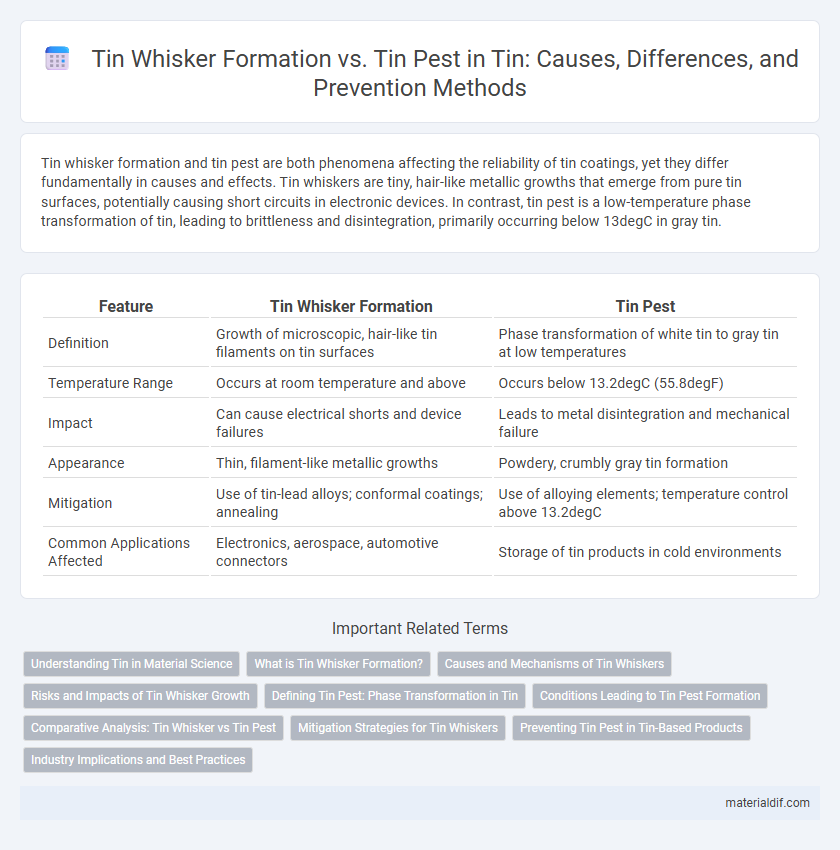

| Feature | Tin Whisker Formation | Tin Pest |

|---|---|---|

| Definition | Growth of microscopic, hair-like tin filaments on tin surfaces | Phase transformation of white tin to gray tin at low temperatures |

| Temperature Range | Occurs at room temperature and above | Occurs below 13.2degC (55.8degF) |

| Impact | Can cause electrical shorts and device failures | Leads to metal disintegration and mechanical failure |

| Appearance | Thin, filament-like metallic growths | Powdery, crumbly gray tin formation |

| Mitigation | Use of tin-lead alloys; conformal coatings; annealing | Use of alloying elements; temperature control above 13.2degC |

| Common Applications Affected | Electronics, aerospace, automotive connectors | Storage of tin products in cold environments |

Understanding Tin in Material Science

Tin whisker formation involves the spontaneous growth of fine, hair-like metallic filaments from the surface of tin coatings, posing reliability risks in electronic components due to potential short circuits. Tin pest, a low-temperature phase transformation from metallic white tin (beta-tin) to non-metallic gray tin (alpha-tin), leads to material degradation and loss of mechanical integrity below 13degC. Understanding these phenomena is crucial in material science to improve tin's performance and durability in various industrial applications.

What is Tin Whisker Formation?

Tin whisker formation is a phenomenon where thin, hair-like metallic filaments grow spontaneously from the surface of tin coatings, often in pure or nearly pure tin finishes. These whiskers can cause electrical short circuits in electronic devices by bridging conductive paths, posing reliability risks in aerospace, automotive, and telecommunications industries. The growth mechanism is believed to be driven by compressive stress within the tin layer, exacerbated by factors such as mechanical stress, temperature fluctuations, and the presence of certain substrates or intermetallic compounds.

Causes and Mechanisms of Tin Whiskers

Tin whisker formation occurs due to compressive stresses in the tin plating, often induced by intermetallic compound growth, mechanical strain, or residual stresses from electroplating. The mechanism involves atomic diffusion driving the spontaneous extrusion of filament-like tin crystals, which can cause short circuits in electronic components. Unlike tin pest, which is a low-temperature phase transformation to gray tin, tin whiskers form independently of temperature changes and are primarily stress-induced phenomena.

Risks and Impacts of Tin Whisker Growth

Tin whisker growth poses significant reliability risks in electronic components by creating conductive filaments that can cause short circuits and device failure, especially in high-reliability sectors such as aerospace and medical devices. Unlike tin pest, which is a low-temperature phase transformation causing material degradation, tin whiskers physically bridge electrical contacts leading to catastrophic malfunctions. The uncontrolled formation of tin whiskers threatens operational stability and longevity in electronics using tin-based finishes or soldering, making mitigation strategies crucial for safety and performance.

Defining Tin Pest: Phase Transformation in Tin

Tin pest is a phase transformation phenomenon where metallic white tin (beta-tin) converts into brittle gray tin (alpha-tin) at temperatures below 13.2degC, causing significant structural degradation. This allotropic transformation results in a powdery, non-metallic form that reduces mechanical integrity and electrical conductivity. Unlike tin whisker formation, which involves filament growth on tin surfaces, tin pest fundamentally alters the crystal structure and properties of tin material.

Conditions Leading to Tin Pest Formation

Tin pest formation occurs under low-temperature conditions, typically below 13.2degC (about 56degF), where white, ductile beta-tin transforms into brittle, gray alpha-tin. This phase transformation is driven by temperature-induced changes in crystal structure, causing tin to crumble and lose mechanical integrity. High purity tin and the absence of stabilizing alloying elements such as lead or antimony exacerbate the susceptibility to tin pest formation in cold environments.

Comparative Analysis: Tin Whisker vs Tin Pest

Tin whisker formation involves the growth of tiny, hair-like metallic filaments on the surface of tin coatings, driven primarily by compressive stress and electrochemical migration, posing significant reliability risks in electronic components through short circuits. In contrast, tin pest is a low-temperature phase transformation of gray tin into brittle alpha-tin below 13.2degC, leading to mechanical degradation and material disintegration without electrical hazards. While tin whiskers compromise electronic functionality by creating conductive pathways, tin pest affects structural integrity, with both phenomena necessitating distinct mitigation strategies in tin-based applications.

Mitigation Strategies for Tin Whiskers

Mitigation strategies for tin whisker formation primarily involve the use of conformal coatings, addition of small amounts of lead or other alloying elements, and temperature control to minimize stress in tin plating. Selecting matte tin finishes over bright tin reduces whisker growth by altering grain structure, while mechanically restraining the tin surface further prevents whisker evolution. These methods are crucial in electronics manufacturing to enhance reliability by preventing short circuits caused by tin whiskers.

Preventing Tin Pest in Tin-Based Products

Preventing tin pest in tin-based products relies heavily on alloying tin with elements such as antimony, bismuth, or lead to stabilize the metallic phase and inhibit the transformation to brittle gray tin at low temperatures. Maintaining operating temperatures above 13.2degC and applying protective coatings can further reduce the risk of tin pest, which causes structural degradation and failure in electronic components and solder joints. Regular inspection and material testing using X-ray diffraction or scanning electron microscopy ensure early detection and mitigation of tin pest before it affects device reliability.

Industry Implications and Best Practices

Tin whisker formation poses significant reliability risks in electronics due to spontaneous conductive filaments causing short circuits, whereas tin pest involves metal embrittlement in low temperatures affecting mechanical integrity. Industries such as aerospace and automotive implement mitigation strategies like whisker-resistant alloys, conformal coatings, and environmental controls to prevent tin whisker growth and tin pest degradation. Best practices include rigorous testing, selecting appropriate tin alloys, and monitoring operating environments to ensure long-term component reliability and performance.

Tin Whisker Formation vs Tin Pest Infographic

materialdif.com

materialdif.com