Sn-Pb alloys offer superior soldering properties with low melting points and excellent wettability, making them highly reliable for electronic connections. Sn-Cu alloys present an eco-friendly alternative with improved mechanical strength and thermal fatigue resistance, though they typically have higher melting points and slightly reduced wettability. The choice between Sn-Pb and Sn-Cu alloys depends on balancing performance requirements with environmental regulations and long-term durability.

Table of Comparison

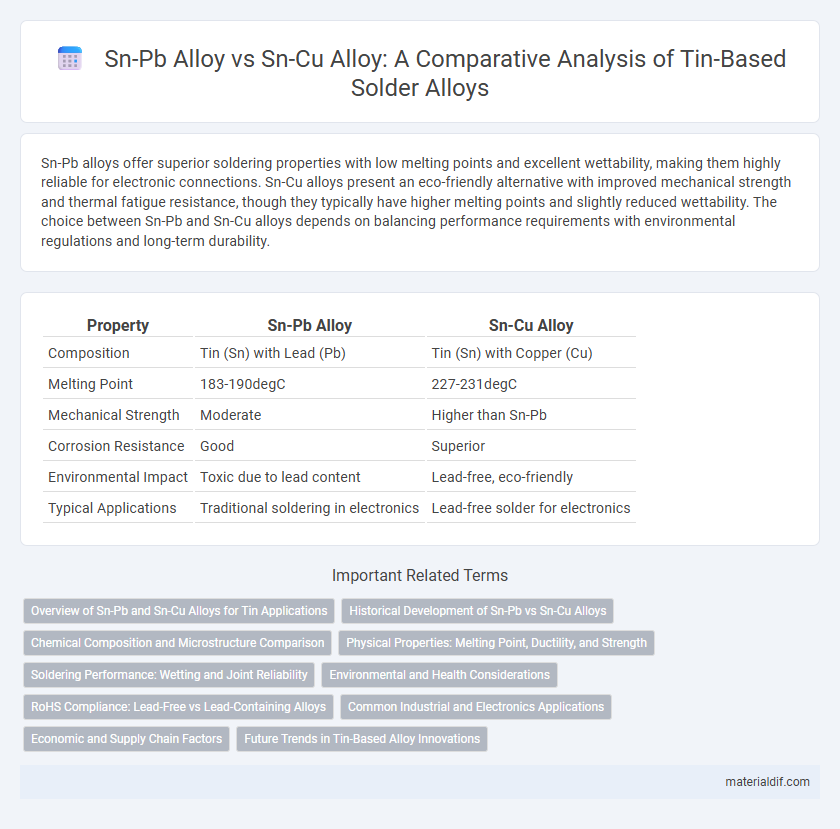

| Property | Sn-Pb Alloy | Sn-Cu Alloy |

|---|---|---|

| Composition | Tin (Sn) with Lead (Pb) | Tin (Sn) with Copper (Cu) |

| Melting Point | 183-190degC | 227-231degC |

| Mechanical Strength | Moderate | Higher than Sn-Pb |

| Corrosion Resistance | Good | Superior |

| Environmental Impact | Toxic due to lead content | Lead-free, eco-friendly |

| Typical Applications | Traditional soldering in electronics | Lead-free solder for electronics |

Overview of Sn-Pb and Sn-Cu Alloys for Tin Applications

Sn-Pb alloys, historically dominant in soldering due to their excellent wettability and low melting points around 183-190degC, offer reliable mechanical strength and good electrical conductivity in electronic applications. Sn-Cu alloys serve as lead-free alternatives with melting points near 227-230degC, providing improved environmental compliance and robust mechanical properties in solder joints, though they may show different wettability and thermal fatigue characteristics compared to Sn-Pb. Both alloy systems are critical in tin applications, with Sn-Pb valued for conventional electronics and Sn-Cu favored in lead-free solders aligned with RoHS regulations.

Historical Development of Sn-Pb vs Sn-Cu Alloys

The Sn-Pb alloy, historically dominant in soldering applications since the early 20th century, offered excellent mechanical and electrical properties but faced decline due to environmental regulations like RoHS restricting lead use. Sn-Cu alloys emerged as lead-free alternatives in the early 2000s, driven by growing demand for eco-friendly materials and improved thermal fatigue resistance. Continuous advancements in Sn-Cu alloy formulations have enhanced their wettability and mechanical robustness, enabling widespread adoption across electronics manufacturing.

Chemical Composition and Microstructure Comparison

Sn-Pb alloys typically consist of approximately 60-63% Sn and 37-40% Pb, forming a eutectic microstructure with distinct Sn and Pb phases that provide good mechanical properties and corrosion resistance. Sn-Cu alloys, often containing around 0.7-1.0% Cu with the remainder Sn, exhibit a microstructure characterized by the formation of intermetallic compounds such as Cu6Sn5, which enhance hardness and thermal fatigue resistance. The chemical composition differences directly influence the microstructural features, where Sn-Pb alloys show a more ductile lamellar eutectic structure while Sn-Cu alloys present a more brittle but stronger intermetallic phase dispersion.

Physical Properties: Melting Point, Ductility, and Strength

Sn-Pb alloys typically exhibit a lower melting point around 183degC due to the eutectic composition, providing excellent solderability. Sn-Cu alloys have a higher melting point ranging from 227degC to 235degC but offer enhanced mechanical strength and corrosion resistance. While Sn-Pb alloys offer superior ductility making them ideal for delicate electronic connections, Sn-Cu alloys provide greater tensile strength suitable for high-stress mechanical applications.

Soldering Performance: Wetting and Joint Reliability

Sn-Pb alloys exhibit superior wetting properties and consistently form strong metallurgical bonds, ensuring high joint reliability in traditional soldering applications. Sn-Cu alloys, while environmentally friendly and lead-free, tend to have slower wetting dynamics and slightly reduced joint strength, which can impact long-term reliability under thermal cycling. Optimization of flux chemistry and process parameters is crucial to enhance wetting behavior and ensure robust solder joints in Sn-Cu based Pb-free soldering systems.

Environmental and Health Considerations

Sn-Pb alloys pose significant environmental and health risks due to lead's toxicity, causing neurological damage and bioaccumulation in ecosystems. Sn-Cu alloys offer a safer alternative with lower toxicity, reducing hazardous waste and minimizing exposure-related health problems. Regulatory bodies increasingly restrict Sn-Pb use, promoting Sn-Cu alloys to meet environmental compliance and workplace safety standards.

RoHS Compliance: Lead-Free vs Lead-Containing Alloys

Sn-Cu alloys are fully RoHS compliant as lead-free alternatives, eliminating toxic lead content found in traditional Sn-Pb alloys. Lead-containing Sn-Pb alloys fail to meet RoHS standards due to hazardous lead levels exceeding 0.1%. Switching to Sn-Cu alloys ensures environmental safety and regulatory adherence in electronic soldering applications.

Common Industrial and Electronics Applications

Sn-Pb alloys remain prevalent in electronics soldering due to their excellent wetting properties, low melting point, and reliability in creating airtight joints for printed circuit boards (PCBs). Sn-Cu alloys serve as lead-free alternatives with improved mechanical strength and corrosion resistance, widely utilized in automotive electronics and consumer devices to meet environmental regulations like RoHS. Both alloys are crucial in industrial manufacturing, with Sn-Pb preferred for legacy systems and Sn-Cu favored in modern green electronics production.

Economic and Supply Chain Factors

Sn-Pb alloys are often more cost-effective due to the lower price and widespread availability of lead, but increasing environmental regulations are driving demand for lead-free alternatives like Sn-Cu alloys. Sn-Cu alloys benefit from a more stable and sustainable supply chain, relying on abundant copper deposits that reduce supply risk and price volatility. Economic factors favor Sn-Cu in markets emphasizing environmental compliance and long-term stability despite potentially higher initial costs.

Future Trends in Tin-Based Alloy Innovations

Sn-Cu alloys are gaining traction as environmentally friendly alternatives to traditional Sn-Pb alloys due to stricter regulations on lead use in electronics. Innovations in tin-based alloys emphasize enhancing mechanical strength, thermal fatigue resistance, and solder joint reliability, with Sn-Cu compositions being optimized for advanced electronics packaging. Future trends include developing lead-free solder materials with improved performance through microalloying and nanostructured modifications in Sn-Cu systems to meet growing demand in automotive and consumer electronics industries.

Sn-Pb alloy vs Sn-Cu alloy Infographic

materialdif.com

materialdif.com