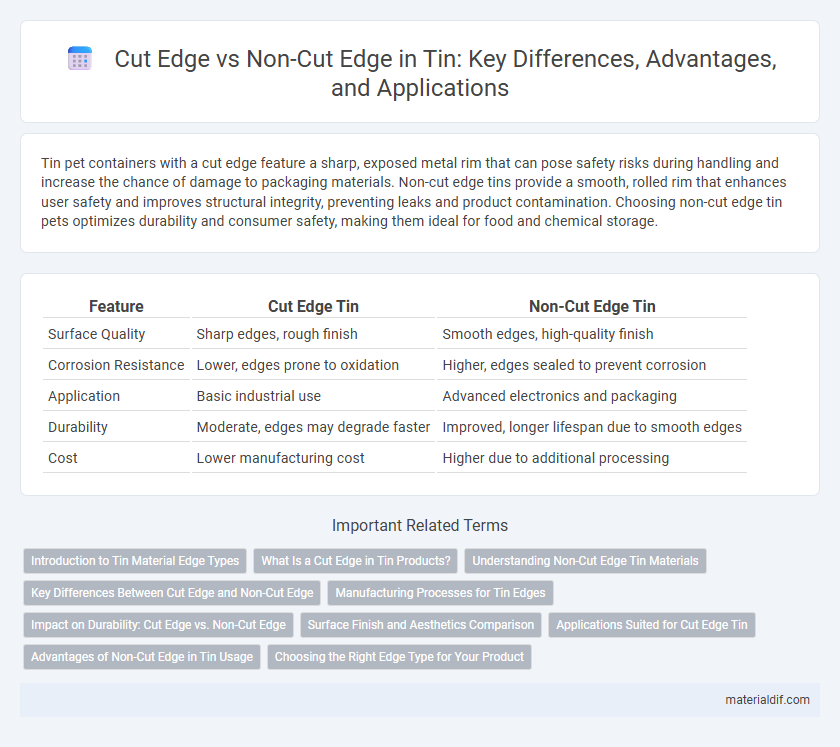

Tin pet containers with a cut edge feature a sharp, exposed metal rim that can pose safety risks during handling and increase the chance of damage to packaging materials. Non-cut edge tins provide a smooth, rolled rim that enhances user safety and improves structural integrity, preventing leaks and product contamination. Choosing non-cut edge tin pets optimizes durability and consumer safety, making them ideal for food and chemical storage.

Table of Comparison

| Feature | Cut Edge Tin | Non-Cut Edge Tin |

|---|---|---|

| Surface Quality | Sharp edges, rough finish | Smooth edges, high-quality finish |

| Corrosion Resistance | Lower, edges prone to oxidation | Higher, edges sealed to prevent corrosion |

| Application | Basic industrial use | Advanced electronics and packaging |

| Durability | Moderate, edges may degrade faster | Improved, longer lifespan due to smooth edges |

| Cost | Lower manufacturing cost | Higher due to additional processing |

Introduction to Tin Material Edge Types

Tin material edge types include cut edge and non-cut edge, which differ primarily in their formation and application. Cut edge tin refers to sheets trimmed to size, resulting in exposed and often sharper edges prone to oxidation and corrosion. Non-cut edge tin retains its original, untrimmed edge with a smoother, protective coating, enhancing durability in industrial and packaging uses.

What Is a Cut Edge in Tin Products?

A cut edge in tin products refers to the exposed metal surface created when the tin coating is sliced or trimmed, often occurring during manufacturing or fabrication processes. This exposed edge lacks the protective tin layer, making it more susceptible to corrosion, oxidation, and rust compared to non-cut edges that retain a continuous tin coating. Proper treatment or sealing of cut edges is essential to maintain the durability and corrosion resistance of tin-based materials.

Understanding Non-Cut Edge Tin Materials

Non-cut edge tin materials, also known as non-cut edge tinplate, feature a protective coating that extends over the entire surface without any exposed cut edges, enhancing corrosion resistance and durability in packaging applications. This type of tin maintains its integrity under mechanical stress and minimizes the risk of oxidation and contamination, which is critical for food and pharmaceutical containers. Understanding the properties of non-cut edge tin helps manufacturers select materials that ensure longer shelf life and superior product safety.

Key Differences Between Cut Edge and Non-Cut Edge

Cut edge refers to the freshly exposed surface of tin after it has been mechanically cut or sheared, which is typically more reactive and prone to oxidation and corrosion. Non-cut edge, in contrast, is the untouched, original surface of the tin that retains its protective oxide layer, providing better resistance to environmental factors. The key difference lies in their susceptibility to corrosion and the need for additional protective treatments on cut edges to maintain tin's durability.

Manufacturing Processes for Tin Edges

Cut edge tin surfaces commonly arise from stamping or cutting processes that expose bare metal, increasing susceptibility to oxidation and corrosion, which requires protective coatings in manufacturing to maintain solderability and durability. Non-cut edge tin finishes, achieved through plating or electro-deposition, provide uniform coverage and superior corrosion resistance by avoiding exposed edges, enhancing long-term reliability in electronic components. Selecting appropriate manufacturing processes for tin edges influences product performance, emphasizing precision in metal treatment and protective layer application to optimize conductivity and protection.

Impact on Durability: Cut Edge vs. Non-Cut Edge

Cut edge tin surfaces expose raw metal that is more susceptible to oxidation, leading to decreased corrosion resistance and reduced durability in electronic components. Non-cut edge tin maintains a continuous protective layer that minimizes exposure to environmental factors, thereby enhancing long-term reliability. The presence of cut edges often requires additional protective coatings to prevent premature failure in tin-plated parts.

Surface Finish and Aesthetics Comparison

Cut edge tin coatings exhibit a rougher surface finish compared to non-cut edge coatings due to exposure of the base metal, leading to potential corrosion and diminished visual appeal. Non-cut edge tin provides a smoother, more uniform surface finish that enhances the aesthetic quality and ensures better protection against environmental factors. Surface finish consistency in non-cut edge tin is critical for applications requiring superior appearance and durability.

Applications Suited for Cut Edge Tin

Cut edge tin excels in applications requiring strong adhesion and enhanced corrosion resistance, such as in printed circuit boards and electrical contacts. Its exposed tin edges provide superior solderability and improved mechanical bonding compared to non-cut edge tin surfaces. Industries relying on high-reliability electronic components prefer cut edge tin for consistent performance under thermal and environmental stress.

Advantages of Non-Cut Edge in Tin Usage

Non-cut edge tin offers superior corrosion resistance by eliminating exposed metal edges prone to oxidation, enhancing the longevity of coated surfaces. This feature improves the integrity of tin-plated components in electronics and food packaging, reducing contamination risks. The seamless finish also provides better solderability and mechanical strength compared to cut edge surfaces, optimizing performance in industrial applications.

Choosing the Right Edge Type for Your Product

Cut edge tin provides a clean, sharp finish ideal for products requiring precise sealing and aesthetic appeal, enhancing durability against corrosion. Non-cut edge tin offers a smoother, safer edge, reducing the risk of injury during handling and assembly, making it suitable for consumer goods and packaging. Selecting between cut edge and non-cut edge tin depends on balancing product safety, functionality, and manufacturing requirements.

Cut edge vs Non-cut edge Infographic

materialdif.com

materialdif.com