Tin corrosion involves the chemical breakdown of tin due to environmental factors such as moisture and acids, often leading to the formation of tin salts that compromise the metal's integrity. Tin oxidation, on the other hand, is a surface reaction where tin reacts with oxygen to form a thin, protective oxide layer, commonly called tin oxide, which helps prevent further metal deterioration. Understanding the distinction between corrosion and oxidation is crucial for preserving tin pet materials in various industrial applications.

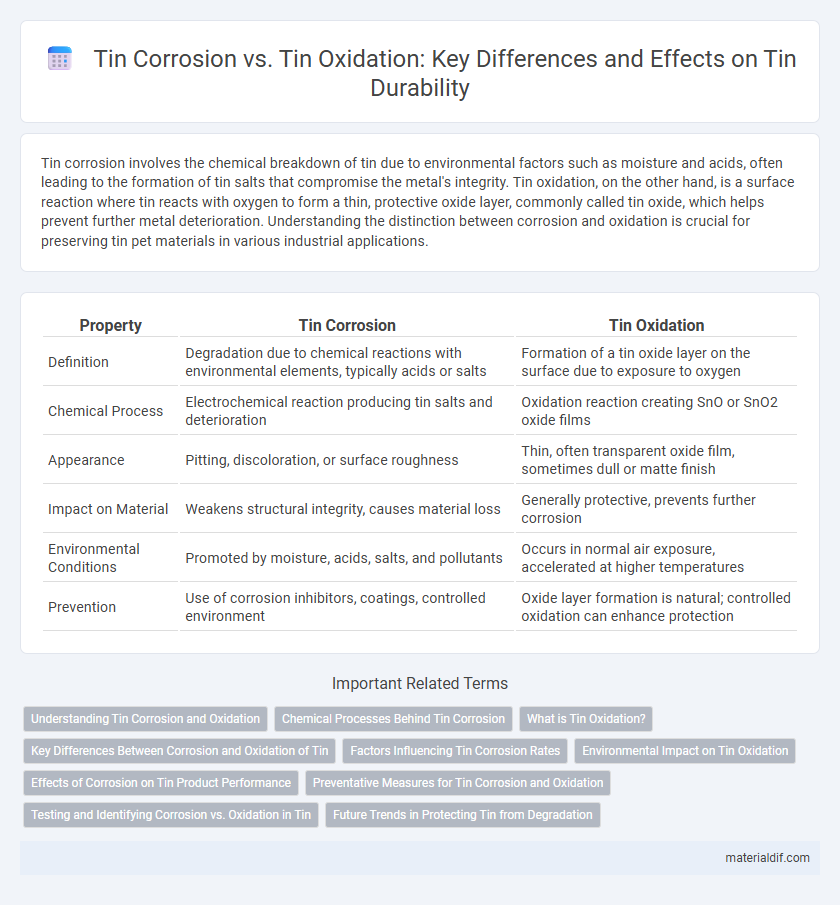

Table of Comparison

| Property | Tin Corrosion | Tin Oxidation |

|---|---|---|

| Definition | Degradation due to chemical reactions with environmental elements, typically acids or salts | Formation of a tin oxide layer on the surface due to exposure to oxygen |

| Chemical Process | Electrochemical reaction producing tin salts and deterioration | Oxidation reaction creating SnO or SnO2 oxide films |

| Appearance | Pitting, discoloration, or surface roughness | Thin, often transparent oxide film, sometimes dull or matte finish |

| Impact on Material | Weakens structural integrity, causes material loss | Generally protective, prevents further corrosion |

| Environmental Conditions | Promoted by moisture, acids, salts, and pollutants | Occurs in normal air exposure, accelerated at higher temperatures |

| Prevention | Use of corrosion inhibitors, coatings, controlled environment | Oxide layer formation is natural; controlled oxidation can enhance protection |

Understanding Tin Corrosion and Oxidation

Tin corrosion primarily occurs when tin reacts with acids, alkalis, or certain salts, leading to the formation of tin salts and material degradation. Tin oxidation is a surface phenomenon where tin forms a thin oxide layer, typically tin oxide (SnO2), that acts as a protective barrier against further corrosion. Understanding the differences between tin corrosion and oxidation is essential for improving the longevity and reliability of tin-coated materials in various industrial applications.

Chemical Processes Behind Tin Corrosion

Tin corrosion primarily involves electrochemical reactions where tin interacts with environmental factors such as moisture and oxygen, forming tin oxides and hydroxides. The chemical process includes the oxidation of tin metal (Sn) to tin ions (Sn2+ or Sn4+) in the presence of water and oxygen, leading to corrosion products like tin oxide (SnO2) that compromise the metal's integrity. Unlike simple oxidation, corrosion of tin also involves ionic exchange and dissolution processes, accelerating material degradation in harsh environments.

What is Tin Oxidation?

Tin oxidation is a chemical reaction where tin metal reacts with oxygen in the environment, forming a thin layer of tin oxide (SnO or SnO2) on its surface. This oxide layer acts as a protective barrier, preventing further corrosion and maintaining the metal's integrity. Unlike tin corrosion, which involves more aggressive degradation processes, tin oxidation primarily results in a stable, passivating coating that enhances tin's durability.

Key Differences Between Corrosion and Oxidation of Tin

Tin corrosion involves the chemical deterioration of tin primarily due to environmental factors such as moisture, acids, or salts, leading to the formation of tin salts or other compounds that degrade the metal's integrity. Tin oxidation refers specifically to the reaction of tin with oxygen forming a stable tin oxide (SnO or SnO2) layer that can provide a protective barrier against further damage. Unlike corrosion, which often causes weakening and material loss, tin oxidation typically results in a passivating film that enhances resistance to further corrosion.

Factors Influencing Tin Corrosion Rates

Tin corrosion rates are significantly influenced by environmental factors such as humidity, temperature, and the presence of aggressive ions like chlorides and sulfides. Oxidation of tin forms a protective oxide layer that can slow corrosion, but this layer's effectiveness diminishes in acidic or saline conditions where corrosion accelerates. Surface treatments, alloy composition, and exposure duration also play critical roles in determining the overall corrosion behavior of tin.

Environmental Impact on Tin Oxidation

Environmental factors such as humidity, temperature, and atmospheric pollutants significantly accelerate tin oxidation, leading to the formation of tin oxide layers that can alter the metal's surface properties and reduce its effectiveness in electronic applications. Unlike tin corrosion, which often involves electrochemical reactions with water and acids, tin oxidation primarily occurs through direct exposure to oxygen and environmental oxidants, resulting in a more controlled but persistent degradation process. The buildup of tin oxide not only affects material performance but also contributes to environmental concerns by influencing the recyclability and lifespan of tin-containing components in various industries.

Effects of Corrosion on Tin Product Performance

Corrosion significantly degrades tin product performance by causing surface pitting and loss of electrical conductivity, which is critical in electronic applications. Unlike simple oxidation that forms a protective tin oxide layer, corrosion leads to the formation of tin salts and other compounds that compromise mechanical integrity and solderability. These effects result in increased resistance, reduced lifespan, and failure of tin-coated components in harsh environments.

Preventative Measures for Tin Corrosion and Oxidation

Preventative measures for tin corrosion and oxidation include applying protective coatings such as lacquers or polymers to create a barrier against moisture and oxygen. Maintaining controlled environmental conditions like low humidity and minimal exposure to corrosive agents significantly reduces the risk of tin surface degradation. Utilizing alloying techniques with elements like copper or silver enhances tin's resistance by improving its microstructure and reducing susceptibility to oxidation and corrosion.

Testing and Identifying Corrosion vs. Oxidation in Tin

Testing and identifying corrosion versus oxidation in tin involves analyzing surface morphology and chemical composition using techniques such as scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX). Corrosion typically presents as localized pitting or intergranular attack with tin compounds like tin chloride or oxides with contaminants, while oxidation results in a uniform tin oxide (SnO or SnO2) layer. Electrochemical impedance spectroscopy (EIS) and X-ray photoelectron spectroscopy (XPS) provide quantitative data distinguishing corrosion products from passive oxide films on tin surfaces.

Future Trends in Protecting Tin from Degradation

Future trends in protecting tin from degradation emphasize advanced coatings that enhance resistance to both corrosion and oxidation, including the development of nano-engineered surface treatments and alloying with elements like silver or copper to improve durability. Innovations in environmentally friendly inhibitors derived from sustainable materials are gaining traction to minimize ecological impact while maintaining effectiveness. Research also targets smart, self-healing coatings capable of repairing microscopic damage, extending the lifespan of tin in electronic and industrial applications.

Tin corrosion vs Tin oxidation Infographic

materialdif.com

materialdif.com