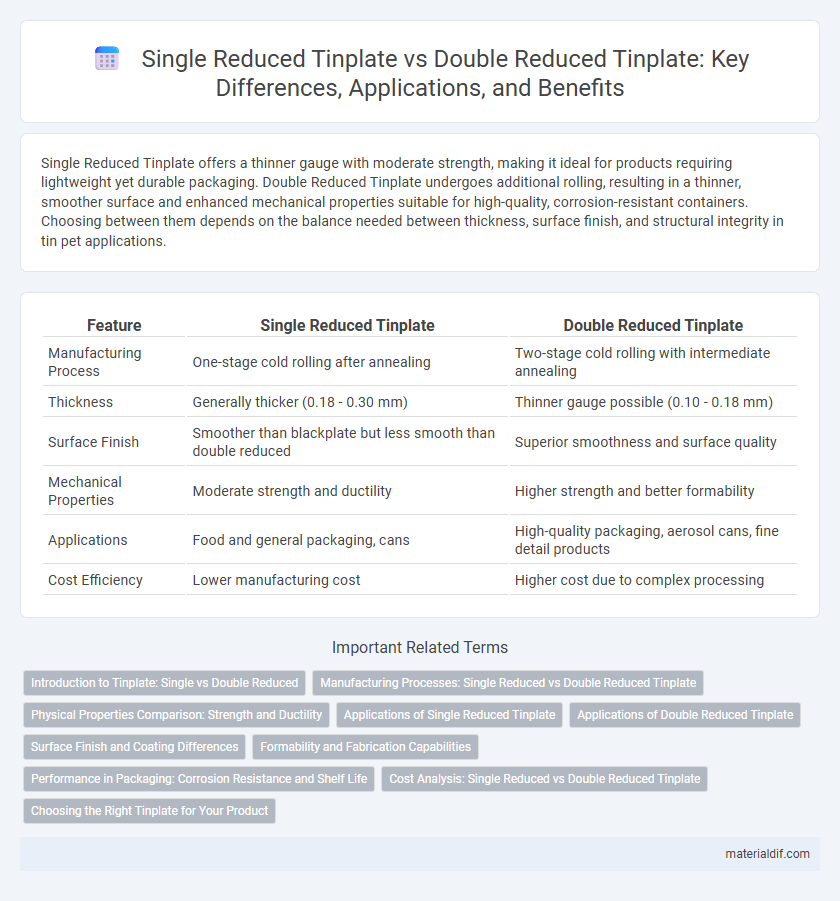

Single Reduced Tinplate offers a thinner gauge with moderate strength, making it ideal for products requiring lightweight yet durable packaging. Double Reduced Tinplate undergoes additional rolling, resulting in a thinner, smoother surface and enhanced mechanical properties suitable for high-quality, corrosion-resistant containers. Choosing between them depends on the balance needed between thickness, surface finish, and structural integrity in tin pet applications.

Table of Comparison

| Feature | Single Reduced Tinplate | Double Reduced Tinplate |

|---|---|---|

| Manufacturing Process | One-stage cold rolling after annealing | Two-stage cold rolling with intermediate annealing |

| Thickness | Generally thicker (0.18 - 0.30 mm) | Thinner gauge possible (0.10 - 0.18 mm) |

| Surface Finish | Smoother than blackplate but less smooth than double reduced | Superior smoothness and surface quality |

| Mechanical Properties | Moderate strength and ductility | Higher strength and better formability |

| Applications | Food and general packaging, cans | High-quality packaging, aerosol cans, fine detail products |

| Cost Efficiency | Lower manufacturing cost | Higher cost due to complex processing |

Introduction to Tinplate: Single vs Double Reduced

Single reduced tinplate undergoes a single rolling reduction, resulting in moderate strength and ductility suitable for general packaging applications. Double reduced tinplate involves an additional rolling pass, enhancing its surface finish, strength, and formability, making it ideal for more demanding uses such as severe drawing and forming. The choice between single and double reduced tinplate depends on specific mechanical properties and coating quality required in various industrial processes.

Manufacturing Processes: Single Reduced vs Double Reduced Tinplate

Single reduced tinplate undergoes a single rolling reduction process during manufacturing, resulting in a thicker and less uniform tin coating with moderate mechanical strength. Double reduced tinplate is subjected to two successive rolling reductions, producing a thinner, more uniform tin coating with enhanced surface smoothness and improved mechanical properties. The double reduction process also increases the steel substrate's strength and ductility, making it more suitable for applications requiring precise forming and superior corrosion resistance.

Physical Properties Comparison: Strength and Ductility

Single Reduced Tinplate offers moderate strength and higher ductility due to its less intensive rolling process, making it suitable for applications requiring flexibility. Double Reduced Tinplate exhibits increased tensile strength and reduced ductility as a result of additional rolling, enhancing its resistance to deformation under stress. The choice between single and double reduced tinplate depends on the balance needed between strength and pliability in industrial applications.

Applications of Single Reduced Tinplate

Single Reduced Tinplate is primarily used in food and beverage can manufacturing due to its excellent corrosion resistance and ease of fabrication. It is ideal for applications requiring moderate mechanical strength and good solderability, such as aerosol containers and general packaging. Single Reduced Tinplate also serves well in electrical components and decorative items where surface finish and protective coating are crucial.

Applications of Double Reduced Tinplate

Double Reduced Tinplate, characterized by its thinner gauge and enhanced surface smoothness compared to Single Reduced Tinplate, finds extensive use in producing lightweight, high-quality packaging materials such as food and beverage cans. Its superior mechanical properties and corrosion resistance make it ideal for applications requiring strict hygiene standards and durability, including aerosol containers and pharmaceutical packaging. The enhanced formability and excellent printability of Double Reduced Tinplate support its widespread adoption in decorative and consumer goods packaging.

Surface Finish and Coating Differences

Single reduced tinplate undergoes one rolling process, resulting in a thicker tin coating and a slightly rougher surface finish suited for general packaging applications. Double reduced tinplate experiences two rolling stages, producing a smoother surface finish with a thinner, more uniform tin coating ideal for high-quality printing and enhanced corrosion resistance. The double reduction enhances mechanical strength and appearance, making it preferable for premium food and beverage cans requiring superior surface properties.

Formability and Fabrication Capabilities

Single Reduced Tinplate exhibits superior formability due to its thicker gauge, allowing easier shaping and bending without cracking, making it ideal for intricate fabrication processes. Double Reduced Tinplate offers enhanced strength and surface smoothness, beneficial for applications requiring finer finishes but may present challenges in complex forming operations. Manufacturers often select Single Reduced Tinplate for products needing high ductility, while Double Reduced Tinplate suits components demanding precision and durability.

Performance in Packaging: Corrosion Resistance and Shelf Life

Single Reduced Tinplate offers good corrosion resistance suitable for standard packaging applications, but Double Reduced Tinplate provides superior performance with enhanced corrosion resistance and longer shelf life due to its finer grain structure and increased mechanical strength. The double reduction process refines the metal surface, resulting in a denser tin coating that better protects against acidic and humid environments commonly encountered in food and beverage packaging. Consequently, Double Reduced Tinplate is preferred for products requiring extended preservation and enhanced durability during transportation and storage.

Cost Analysis: Single Reduced vs Double Reduced Tinplate

Single Reduced Tinplate typically offers a lower production cost due to its simpler rolling process, making it more cost-effective for applications requiring moderate strength and thickness. Double Reduced Tinplate undergoes an additional rolling pass, increasing manufacturing expenses but providing enhanced surface finish, strength, and uniformity suitable for high-quality packaging. The cost analysis favors Single Reduced Tinplate for budget-sensitive projects, whereas Double Reduced Tinplate justifies higher costs through improved performance and durability in demanding environments.

Choosing the Right Tinplate for Your Product

Single Reduced Tinplate offers a durable and cost-effective solution for packaging lighter or less corrosive products, providing sufficient strength with a thinner gauge. Double Reduced Tinplate, produced through an additional rolling process, boasts enhanced surface smoothness and higher strength, making it ideal for products requiring superior protection and aesthetic appeal. Selecting the right tinplate depends on the product's packaging requirements, balancing factors like corrosion resistance, mechanical properties, and budget constraints.

Single Reduced Tinplate vs Double Reduced Tinplate Infographic

materialdif.com

materialdif.com