Bare tin offers excellent solderability and corrosion resistance but is prone to oxidation over time, which can affect its conductivity and appearance. Coated tin, typically covered with a thin layer of inert material like nickel or a polymer, provides enhanced protection against oxidation and environmental factors, extending the lifespan and reliability of electronic components. The choice between bare and coated tin depends on the specific application requirements, balancing cost, durability, and performance.

Table of Comparison

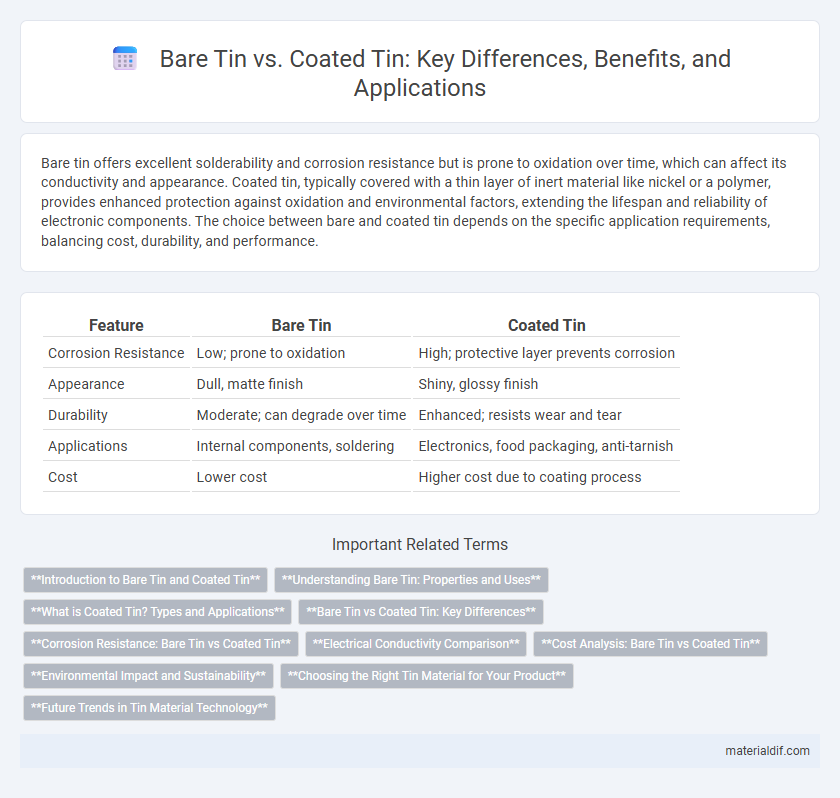

| Feature | Bare Tin | Coated Tin |

|---|---|---|

| Corrosion Resistance | Low; prone to oxidation | High; protective layer prevents corrosion |

| Appearance | Dull, matte finish | Shiny, glossy finish |

| Durability | Moderate; can degrade over time | Enhanced; resists wear and tear |

| Applications | Internal components, soldering | Electronics, food packaging, anti-tarnish |

| Cost | Lower cost | Higher cost due to coating process |

Introduction to Bare Tin and Coated Tin

Bare tin is a form of tin plating that provides excellent solderability and corrosion resistance without any additional protective layers, widely used in electronic and food packaging industries. Coated tin, on the other hand, involves a thin layer of protective material such as nickel or organic compounds applied over the tin to enhance durability, prevent tarnishing, and improve shelf life. The choice between bare tin and coated tin depends on application requirements such as environmental exposure, mechanical wear, and long-term performance.

Understanding Bare Tin: Properties and Uses

Bare tin offers excellent corrosion resistance, high electrical conductivity, and good solderability, making it ideal for electronic components and food packaging applications. Its natural metallic luster and softness facilitate easy appliance in thin layers or plating processes. Common uses include solder coatings, protective layers on steel, and applications requiring non-toxic, lead-free metal surfaces.

What is Coated Tin? Types and Applications

Coated tin refers to tin that has been treated with a protective layer to enhance corrosion resistance, solderability, and electrical conductivity for various industrial uses. Common types of coated tin include electroplated tin, tin-lead, tin-copper, and organic coatings such as polymer films, which cater to diverse applications in electronics, food packaging, and automotive parts. These coatings prevent oxidation and improve surface durability, making coated tin ideal for printed circuit boards, food cans, and connectors where long-term reliability and safety are critical.

Bare Tin vs Coated Tin: Key Differences

Bare tin consists of pure tin metal exposed directly to the environment, offering excellent solderability but prone to oxidation and corrosion over time. Coated tin features a protective layer, often of nickel or other alloys, which enhances corrosion resistance and extends the lifespan of electronic components. The key differences lie in durability and environmental protection, with bare tin favored for cost-efficiency and coated tin chosen for applications requiring higher reliability.

Corrosion Resistance: Bare Tin vs Coated Tin

Bare tin offers moderate corrosion resistance primarily through its natural oxide layer, which protects against mild environmental factors. Coated tin enhances corrosion resistance significantly by incorporating protective layers, such as nickel or polymer coatings, that prevent oxidation and chemical degradation in harsher environments. For applications requiring prolonged exposure to moisture or corrosive agents, coated tin provides superior durability and longevity compared to bare tin.

Electrical Conductivity Comparison

Bare tin exhibits higher electrical conductivity compared to coated tin due to the absence of additional material layers that can impede electron flow. Coated tin, often covered with nickel, silver, or organic layers, experiences slight resistance increases, affecting its performance in sensitive electronic applications. The choice between bare and coated tin depends on the balance between conductivity requirements and corrosion resistance needs.

Cost Analysis: Bare Tin vs Coated Tin

Bare tin offers a lower upfront cost compared to coated tin due to the absence of additional protective layers, making it economically advantageous for applications with minimal corrosion risk. Coated tin incurs higher expenses because of the extra materials and processes involved in applying protective coatings, which enhance durability and corrosion resistance. Long-term cost analysis must consider maintenance, lifespan, and potential failure rates, where coated tin often delivers better value despite its higher initial price.

Environmental Impact and Sustainability

Bare tin offers a lower environmental footprint due to its minimal processing requirements and higher recyclability compared to coated tin, which involves additional chemical treatments that may introduce toxic substances. Coated tin often uses organic or inorganic layers that can complicate recycling processes and increase waste management challenges. Sustainable practices favor bare tin for its reduced energy consumption during production and simpler end-of-life recovery, contributing to a smaller ecological impact.

Choosing the Right Tin Material for Your Product

Choosing the right tin material for your product depends on factors like corrosion resistance, conductivity, and cost. Bare tin offers excellent electrical conductivity and solderability but is prone to oxidation, affecting durability. Coated tin, often layered with protective metals or polymers, enhances corrosion resistance and extends product lifespan in harsh environments.

Future Trends in Tin Material Technology

Future trends in tin material technology emphasize the development of advanced coated tin layers to enhance corrosion resistance and electrical conductivity compared to bare tin. Innovations in nano-coating techniques and alloyed tin composites aim to improve solderability and reduce tin whisker formation in electronics. Increasing adoption of eco-friendly, lead-free tin coatings is driving sustainability in manufacturing processes.

Bare Tin vs Coated Tin Infographic

materialdif.com

materialdif.com