White tin and grey tin represent two distinct allotropes of tin with different physical properties and applications. White tin, stable at room temperature, exhibits a metallic luster and higher density, making it ideal for soldering and plating industries. Grey tin, a brittle non-metallic form appearing at low temperatures, transforms back to white tin when warmed, limiting its practical use but influencing tin's performance in cold environments.

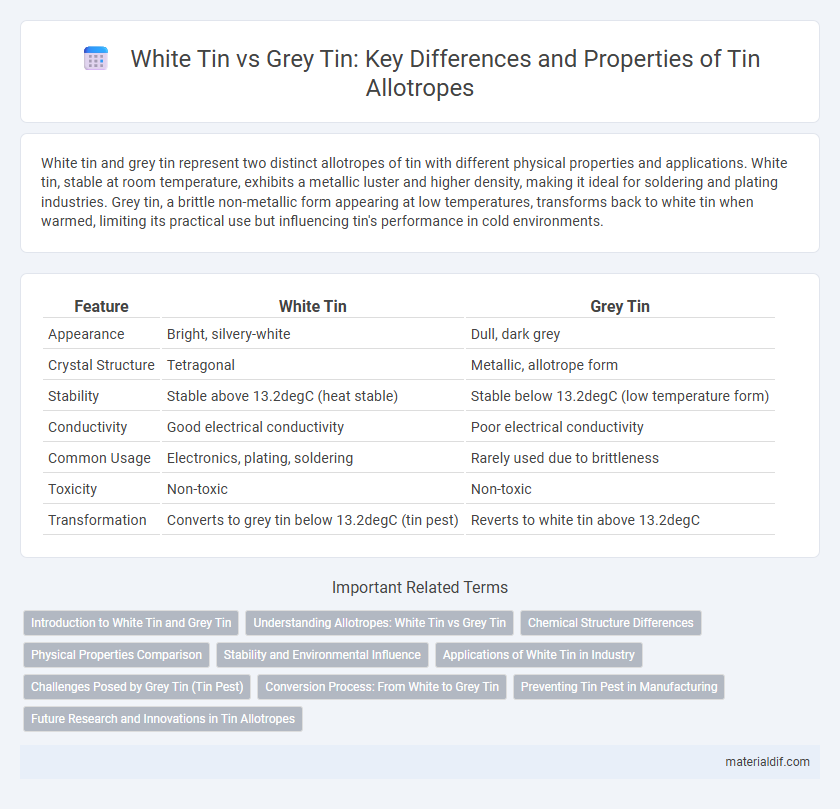

Table of Comparison

| Feature | White Tin | Grey Tin |

|---|---|---|

| Appearance | Bright, silvery-white | Dull, dark grey |

| Crystal Structure | Tetragonal | Metallic, allotrope form |

| Stability | Stable above 13.2degC (heat stable) | Stable below 13.2degC (low temperature form) |

| Conductivity | Good electrical conductivity | Poor electrical conductivity |

| Common Usage | Electronics, plating, soldering | Rarely used due to brittleness |

| Toxicity | Non-toxic | Non-toxic |

| Transformation | Converts to grey tin below 13.2degC (tin pest) | Reverts to white tin above 13.2degC |

Introduction to White Tin and Grey Tin

White tin, also known as beta tin, is a metallic allotrope of tin that is stable at temperatures above 13.2degC and exhibits a tetragonal crystal structure characterized by its silvery appearance and high ductility. Grey tin, or alpha tin, transforms from white tin below 13.2degC and features a diamond cubic crystal lattice, resulting in a nonmetallic, brittle form that resembles powdered tin. The transformation between white and grey tin, called tin pest, significantly affects tin's mechanical properties and is critical in applications requiring temperature stability.

Understanding Allotropes: White Tin vs Grey Tin

White tin (beta-tin) and grey tin (alpha-tin) are allotropes of tin that differ in crystal structure and physical properties. White tin has a tetragonal structure and is metallic, stable above 13.2degC, while grey tin has a diamond cubic structure, is non-metallic, and forms below 13.2degC through a process called tin pest. The transformation between these allotropes affects tin's applications in soldering and electronics due to changes in brittleness and conductivity.

Chemical Structure Differences

White tin, also known as beta-tin, features a tetragonal crystal structure with atoms arranged in a compact, metallic lattice that provides stability at room temperature. Grey tin, or alpha-tin, exhibits a diamond cubic structure similar to silicon, resulting in a brittle, nonmetallic form that occurs below 13.2degC. The chemical bonding in white tin is metallic with delocalized electrons, whereas grey tin possesses covalent bonding leading to its semiconducting properties.

Physical Properties Comparison

White tin exhibits a metallic luster, greater hardness, and a crystalline tetragonal structure, making it more stable at room temperature compared to grey tin, which has a non-metallic appearance, softer texture, and a diamond cubic crystalline structure. The density of white tin is approximately 7.31 g/cm3, whereas grey tin, or "tin pest," has a significantly lower density around 5.77 g/cm3 due to its expanded lattice. White tin is ductile and malleable, whereas grey tin is brittle and prone to disintegration under cold conditions.

Stability and Environmental Influence

White tin, or beta-tin, exhibits greater stability at room temperature, maintaining its metallic properties, while grey tin, or alpha-tin, is less stable and tends to form under cold, moist environmental conditions, often leading to a brittle, powdery structure. Environmental factors such as low temperature and humidity accelerate the allotropes' transition from white to grey tin, a process known as "tin pest," which compromises the metal's mechanical integrity and electrical conductivity. Controlling temperature and moisture is critical to preserving white tin's stability, especially in applications requiring consistent performance and durability.

Applications of White Tin in Industry

White tin, the metallic form of tin, is widely used in soldering due to its excellent conductivity and low melting point, making it essential in electronics manufacturing. Its corrosion resistance makes it a preferred coating for steel in food packaging and automotive components, extending durability and preventing contamination. The malleability and non-toxic nature of white tin also allow its application in alloys such as bronze and pewter, enhancing strength and workability in industrial processes.

Challenges Posed by Grey Tin (Tin Pest)

Grey tin, known as tin pest, presents significant challenges due to its transformation from metallic white tin at low temperatures, resulting in a brittle, non-metallic form that compromises structural integrity. This phase change causes expansion and disintegration, leading to the failure of tin-based components in cold environments. Preventing tin pest requires alloying white tin with elements like antimony or bismuth to stabilize the metallic phase and enhance durability.

Conversion Process: From White to Grey Tin

The conversion process from white tin (b-tin) to grey tin (a-tin) involves a phase transformation that occurs below 13.2degC, where the metallic white tin structure changes into a brittle, non-metallic grey tin with a diamond cubic lattice. This allotropic transformation causes a volume expansion and disintegration of the material, often referred to as "tin pest" or "tin disease," leading to structural degradation. The process can be accelerated by impurities, temperature fluctuations, and mechanical stresses, severely impacting tin-based components' durability and performance.

Preventing Tin Pest in Manufacturing

White tin, also known as beta tin, remains stable at temperatures above 13.2degC and is preferred in manufacturing for its durability and corrosion resistance. Grey tin, or alpha tin, forms below this temperature and causes tin pest--a degradation phenomenon leading to brittleness and disintegration of tin components. Preventing tin pest involves alloying tin with small amounts of antimony, bismuth, or copper, which stabilizes white tin and ensures product reliability in cold environments.

Future Research and Innovations in Tin Allotropes

Future research in tin allotropes focuses on stabilizing white tin's metallic phase at lower temperatures to enhance its electrical conductivity for advanced electronic applications. Innovations explore alloying techniques and nanostructuring to prevent the transition to grey tin, which degrades material performance due to its brittle, semiconducting nature. Emerging studies investigate dopants and pressure treatments to tailor tin's phase behavior, aiming to develop more durable, high-performance tin-based components for flexible electronics and energy storage devices.

White tin vs Grey tin Infographic

materialdif.com

materialdif.com